Method for synthesizing spherical gradient lithium-rich anode material

A lithium-rich positive electrode material and synthesis method technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as low tap density, harsh hydrothermal synthesis method, and poor rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. In order to coat manganese on the surface of the existing commercial spherical precursor [Ni0.4Co0.2Mn0.4](OH)2, use manganese sulfate as manganese source, according to MnSO4: [Ni0.4Co0.2Mn0. 4] (OH) 2 (Molar ratio)=0.2:0.8, weigh the existing commercial spherical precursor [Ni 0.4 co 0.2 mn 0.4 ](OH) 2 and manganese sulfate, add deionized water to form a suspension, and then stir in a 60°C water bath;

[0031] Weigh the existing commercial spherical precursor [Ni 0.4 co 0.2 mn 0.4 ](OH) 2 After adding manganese sulfate, add deionized water to dissolve, the concentration of the cationic solution is 0.05mol / L, ultrasonically disperse for 1-2h, and place it in a 60°C water bath and stir for 1-2h.

[0032] 2. Prepare 0.05mol / L NaCO 3 solution, the Na with a peristaltic pump 2 CO 3 The solution was added dropwise to the MnSO in 1 4 In the solution, a certain drop rate is controlled so that Na 2 CO 3 solution with Mn adsorbed on the surface of the precursor ...

Embodiment 2

[0039] 1-3 steps are the same as embodiment 1;

[0040] 4. Mix the spherical precursor with a dry coating obtained in step 3 with lithium hydroxide at a molar ratio of 1:1.25 and grind them in an agate mortar for 1 hour. Place it in a tube furnace and heat treat at 450°C for 3 hours, then slowly heat up for 25 hours at 800°C for 12 hours to obtain the desired material.

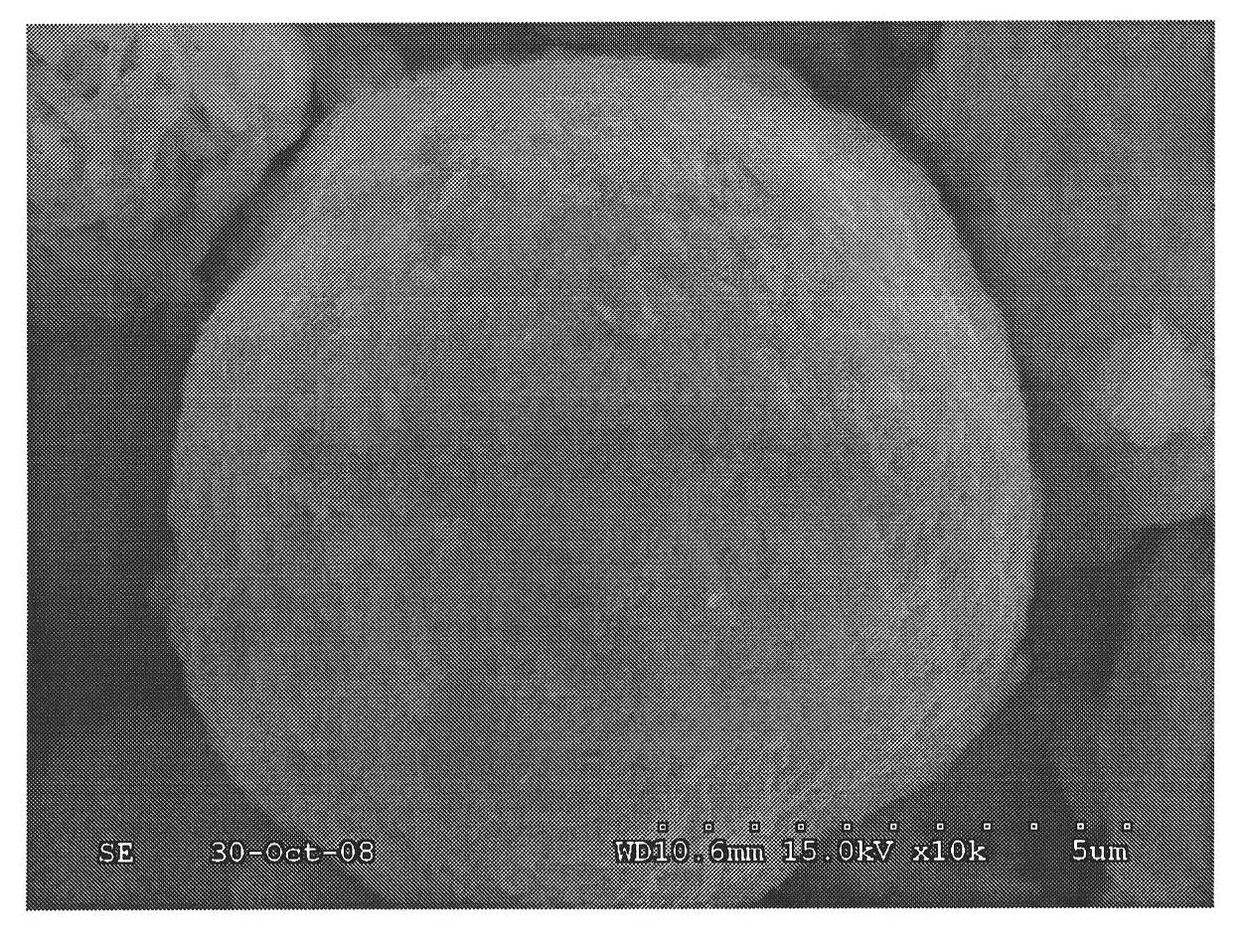

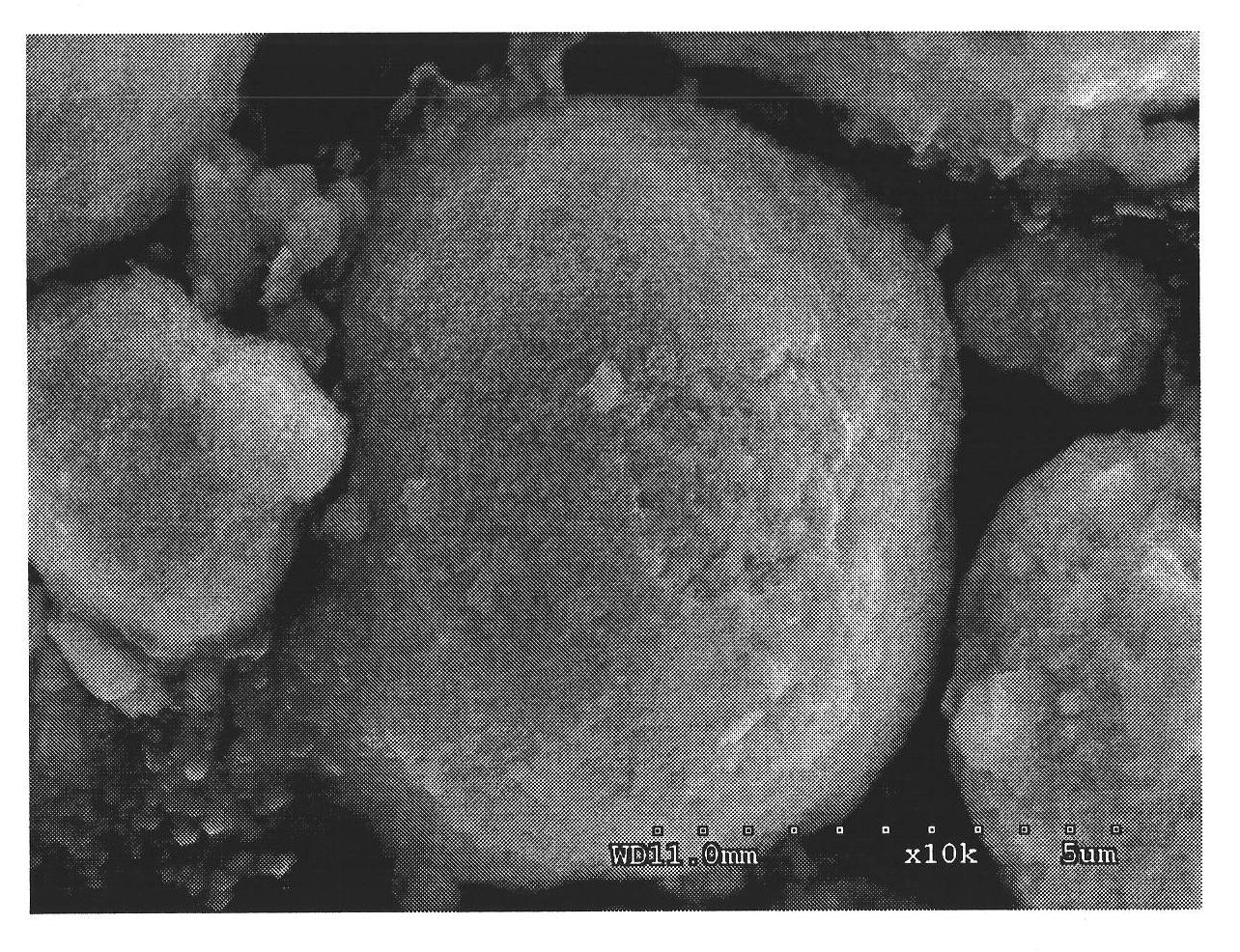

[0041] It can be seen from the morphology that the sample obtained at 800°C is a solid spherical particle with a diameter of about 10 μm. From the EDS energy spectrum to the concentration distribution of Mn element in the particle, it can be concluded that the concentration of Mn element in the sample treated at 800°C is along the The particle diameter gradually decreases from the outside to the inside, showing a certain gradient, but the difference between the surface Mn ion concentration and the internal concentration is slightly lower than that of the sample at 750 °C.

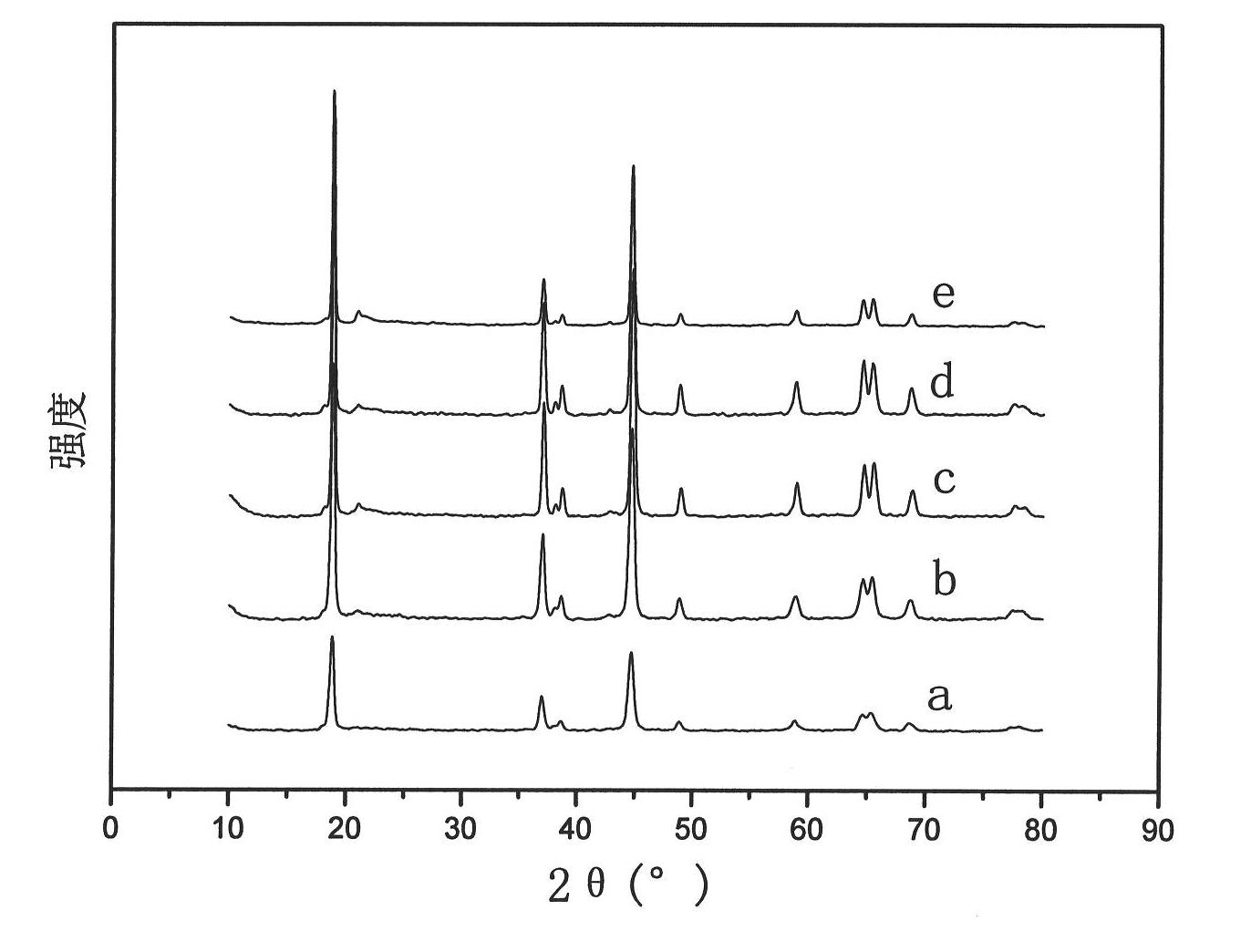

[0042] X-ray diffraction (XRD) anal...

Embodiment 3

[0045] 1-3 steps are the same as embodiment 1;

[0046] 4. Mix the spherical precursor with a dry coating obtained in step 3 with lithium hydroxide at a molar ratio of 1:1.25 and grind them in an agate mortar for 1 hour. Place it in a tube furnace and heat-treat at 450°C for 3 hours, then heat-treat at 850°C for 15 hours after 28 hours of slow temperature rise to obtain the desired material.

[0047] It can be seen from the morphology that the sample obtained at 850°C is a solid spherical particle with a diameter of about 10 μm. From the EDS energy spectrum to the concentration distribution of Mn element in the particle, it can be concluded that the concentration of Mn element in the sample treated at 850°C is along the The gradient of the particle diameter from the outside to the inside is not obvious, and the surface Mn ion concentration is almost equal to the internal concentration. This shows that the increase of sintering temperature makes the distribution of Mn element ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com