Electrode foil feed liquid, and manufacturing method for high strength and low pressure formed foil

A manufacturing method and electrode foil technology, applied in anodizing and other directions, can solve the problems of affecting mechanical strength and low production efficiency, and achieve high production efficiency and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

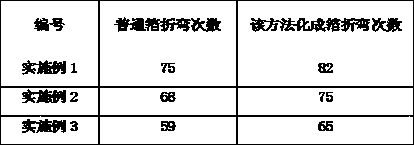

Examples

Embodiment 1

[0012] a) Put the low-pressure corrosion foil in 7wt% ammonium adipate solution at a temperature of 70°C and a current density of 20mA / cm 2 , the voltage is 5v, and anodized for 5 minutes to obtain a primary formed foil;

[0013] b) Place the primary formed foil in 7wt% ammonium adipate solution at a temperature of 70°C and a current density of 20mA / cm 2 , the voltage is 10v, and anodized for 5 minutes to obtain a secondary foil, and the first two stages are powered by conductive rollers;

[0014] c) Place the secondary formed foil in a solution of 5wt% ammonium adipate and 0.005wt% sodium phosphate in the feed tank at a temperature of 30°C and a current density of 30mA / cm 2 , the foil is the cathode, and after 5 minutes of treatment, the feeder tank supplies electricity to the third, fourth and fifth formation tanks in the latter stage;

[0015] d) Place the fed formed foil in a 7wt% ammonium adipate solution at a temperature of 70°C and a current density of 20mA / cm 2 , th...

Embodiment 2

[0023] a) Put the low-pressure corrosion foil in 10wt% ammonium adipate solution at a temperature of 75°C and a current density of 30mA / cm 2 , the voltage is 10v, and anodized for 7 minutes to obtain a primary formed foil;

[0024] b) Place the primary formed foil in 10wt% ammonium adipate solution at a temperature of 75°C and a current density of 30mA / cm 2 , the voltage is 20v, and anodized for 7 minutes to obtain a secondary foil;

[0025] c) Place the secondary formed foil in a 10wt% ammonium adipate solution at a temperature of 75°C and a current density of 30mA / cm 2 , the voltage is 30v, and anodized for 7 minutes to obtain a three-stage forming foil, and the first three stages of formation are powered by conductive rollers;

[0026] d) Place the tertiary formed foil in 7wt% ammonium adipate and 0.01wt% sodium tetraborate and potassium phosphate solution at a temperature of 30°C and a current density of 50mA / cm 2 , the foil is the cathode, and after 3 minutes of treatm...

Embodiment 3

[0034] a) Put the low-pressure corrosion foil in 15wt% ammonium adipate solution, temperature 80°C, current density 50mA / cm 2 , the voltage is 20v, anodized for 10min to obtain a primary foil, and the primary is powered by a conductive roller;

[0035] b) Place the first-grade formed foil in a solution of 5wt% ammonium adipate and 0.03wt% sodium adipate and sodium phosphate in the feed tank at a temperature of 30°C and a current density of 80mA / cm 2 , the foil is the cathode, and it is treated for 3 minutes. The feeder slot supplies electricity to the second and third formation slots in the rear stage;

[0036] c) Place the formed foil in 15wt% ammonium adipate solution at a temperature of 80°C and a current density of 50mA / cm 2 , the voltage is 40v, and anodized for 10min to obtain secondary foil;

[0037] d) Place the secondary formed foil in a 15wt% ammonium adipate solution at a temperature of 80°C and a current density of 50mA / cm 2 , the voltage is 60v, and anodized f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com