Manufacturing method of positive aluminum foil material for pure aluminum-based battery tab

A technology of battery lugs and manufacturing methods, which is applied in the field of aluminum-based batteries, can solve the problems of increased pinholes in processed sheets, prone to pinholes, and increased product failure rate, so as to reduce the difficulty of cutting and avoid sticking knives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

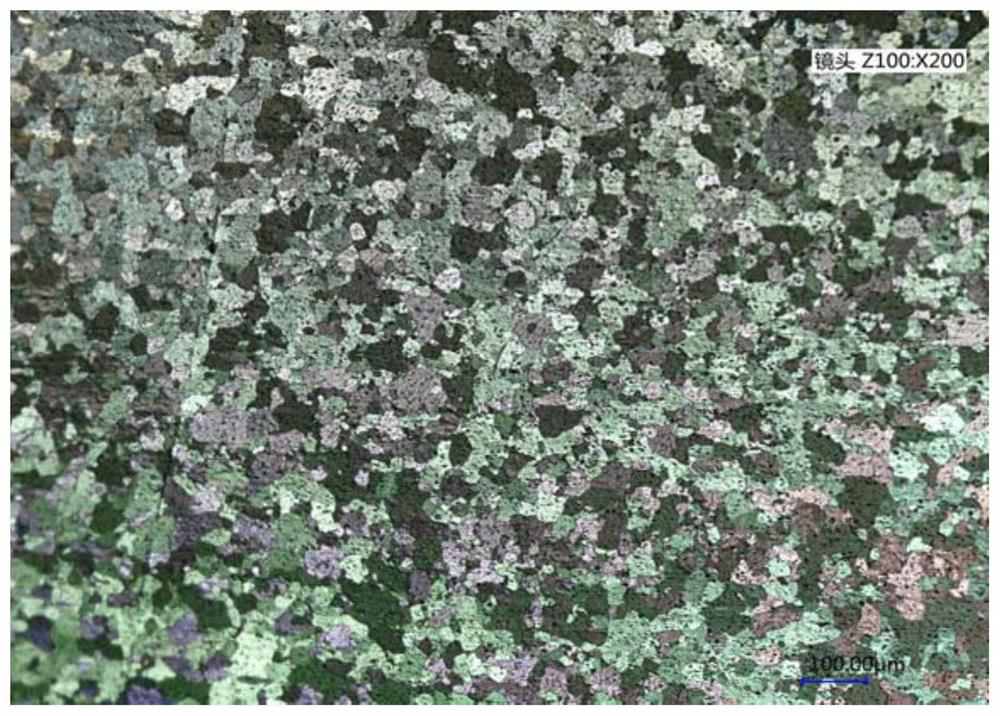

Image

Examples

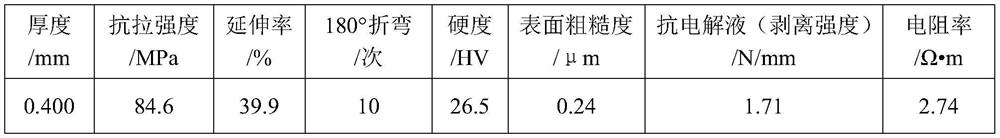

Embodiment 1

[0042] The process of preparing pure aluminum battery pole ears for the positive aluminum foil material is as follows:

[0043] 1. The average heating treatment of the plate ingot: According to the composition of Table 1, the ingot is made at 605 ° C for an average heating insulation of 8h, and then cooled to 550 ° C for 4h.

[0044] Table 1 ingot composition (wt. %)

[0045] FE SI CU Mn Zn MG GA TI Al% 0.4415 0.1469 0.0006 0.0006 0.0017 0.0008 0.0087 0.0218 ≥99.30

[0046] 2. Hot rolling: The opening and rolling temperature of the ingot is 540 ° C, the thickness of 19 streams to 7.0mm, the number of rolled lanes is 40 % -60 %, the rolling speed is 60m / min-100m / min, and the final rolling temperature is obtained. Hot -rolled rolling rolled at 285 ° C.

[0047] 3. A cold rolling: The hot rolling roll is obtained by two -time cold rolling rolling band, the roll roughness is 0.45 μm, and the rolling speed is 300m / min. The band is cleaned, and the steel...

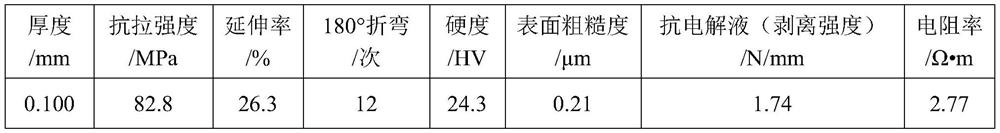

Embodiment 2

[0056] 1. The average heat treatment of the tablet: According to the component of Table 3, the ingot is made at 605 ° C for an average heating heat -insulating 8h, and then the temperature of the heating to 550 ° C is 4h.

[0057] Table 3 ingots ingredients (wt. %)

[0058] FE SI CU Mn Zn MG GA TI Al% 0.4356 0.1382 0.0006 0.0006 0.0019 0.0007 0.0091 0.0215 ≥99.30

[0059] 2. Hot rolling: The opening and rolling temperature of the ingot is 540 ° C, the thickness of 19 streams to 7.0mm, the number of rolled lanes is 40 % -60 %, the rolling speed is 60m / min-100m / min, and the final rolling temperature is obtained. Hot -rolled rolling rolled at 285 ° C.

[0060] 3. A cold rolling: The hot rolling roll is obtained by two -time cold rolling rolling band, the roll roughness is 0.45um, the rolling speed is 300m / min, and the 60#clean oil panel is used before the middle annealing. The band is cleaned, and the steel belt is tightened.

[0061] 4. Intermediate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com