A thin-film electronic device with a vertical structure on a silicon carbide substrate and a manufacturing method thereof

A technology for silicon carbide substrates and electronic devices, which is applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc. It can solve the problems of difficult removal of high-temperature annealing and the inability to use mechanical polishing for ion damage layers, so as to avoid the difficulty of mechanical processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

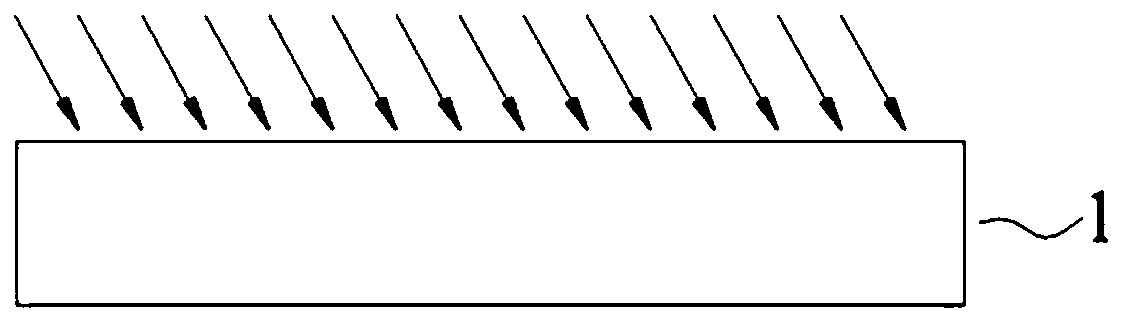

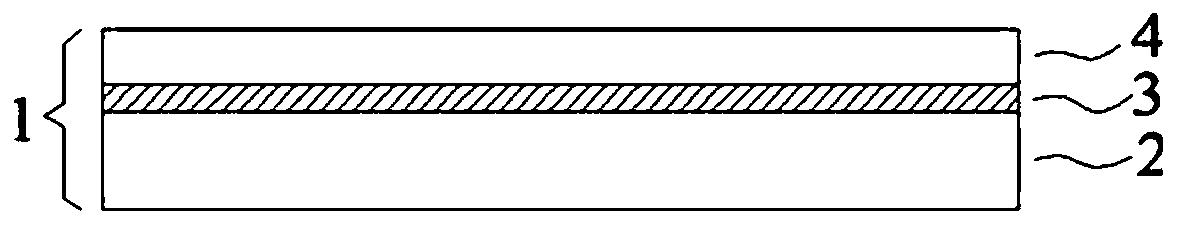

[0060] Such as Figure 1-5 As shown, ion implantation is performed on the upper surface of the n-type conductive silicon carbide semiconductor substrate layer 1, preferably 5 μm or 10 μm; after ion implantation, a layer of ion damage layer 3 is generated under the surface of the semiconductor substrate layer 1, so that the n-type conductive silicon carbide semiconductor The substrate layer 1 is divided into the substrate main body layer 2, the ion damage layer 3 and the silicon carbide film layer 4 located on the upper surface of the ion damage layer 3 from bottom to top; For the n-type silicon carbide epitaxial layer 5 with a low bottom, aluminum ions are implanted on the surface of the epitaxial layer to form p-type conductive points, and nickel is electroplated on the epitaxial layer as a Schottky barrier layer 6 (stress introduction layer). Separate the epitaxial layer and the silicon carbide film layer under the epitaxial layer from the silicon carbide substrate, and use ...

Embodiment 2

[0063] Perform ion implantation on the upper surface of the silicon carbide substrate layer 1, the ion implantation depth is 0.5 μm-20 μm, preferably 5 μm, 10 μm, and 15 μm; after the ion implantation, a layer of ion damage layer 3 is generated under the surface of the silicon carbide substrate layer 1, thereby The n-type conductive silicon carbide semiconductor substrate layer 1 is divided into the substrate main body layer 2, the ion damage layer 3 and the silicon carbide film layer 4 located on the upper surface of the ion damage layer 3 from bottom to top; the ion implantation surface of the silicon carbide film layer 4 Prepare the functional layer (electronic device layer), the electronic device in this embodiment is a semiconductor epitaxial layer 5 grown epitaxially on the upper surface of the silicon carbide substrate 1, or a semiconductor epitaxial layer grown epitaxially on the upper surface of the semiconductor substrate layer 1 5 and the semiconductor electronic dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com