ZnO transparent conductive film and preparing method thereof

A transparent conductive film and thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of increased resistivity, increased resistivity, and low resistivity of transparent conductive films, and achieve high Electrical conductivity, improve electrical conductivity, solve the effect of high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

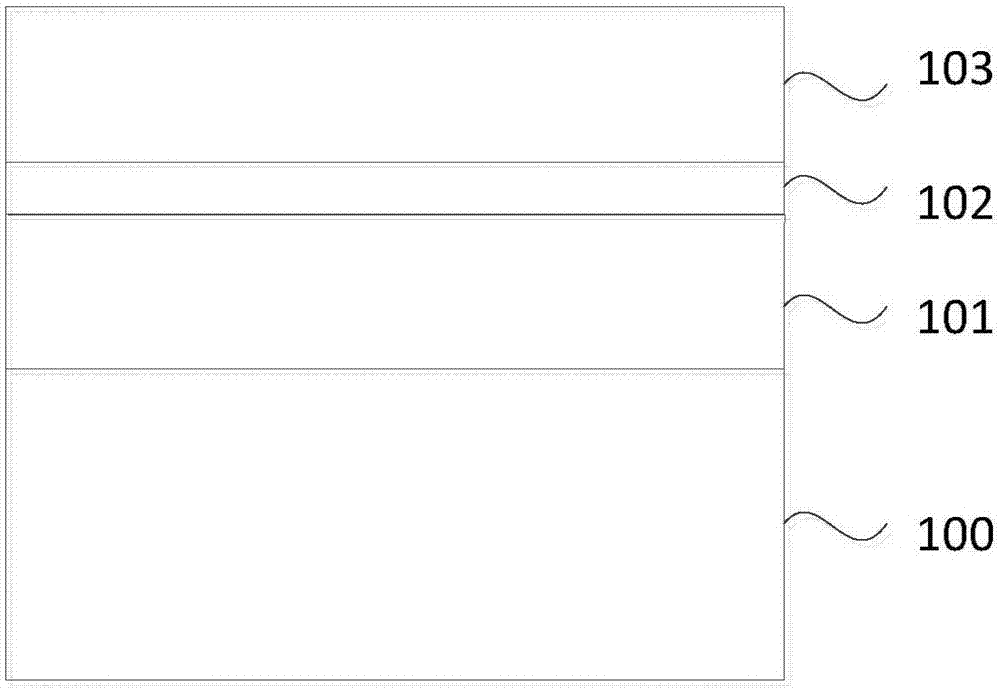

[0039] figure 1 The structural diagram of the ZnO thin film provided in Embodiment 1 of the present invention, this embodiment can be applied to the application fields of transparent conductive thin films specifically include:

[0040] substrate 100;

[0041] a first type epitaxial layer 101 located on the substrate 100;

[0042] An Au plated structural layer 102, located on the side of the first type epitaxial layer 101 away from the substrate 100;

[0043] The second type epitaxial layer 103 is located on the side of the Au-plated structure layer 102 away from the Au-plated structure layer 102 .

[0044] Compared with the pure ZnO film, the film resistivity of the sandwich structure is much lower under the same film thickness. Due to the existence of the Au-plated structure layer, in the thin film of the sandwich structure, there are a large number of free-moving electrons in the metal Au. When the metal and the semiconductor are in contact, the electrons will enter the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com