A positive electrode composite material, coating device, preparation method and application

A technology of positive electrode material and composite material, which is applied in the fields of coating device, positive electrode composite material and preparation, can solve the problems of complex preparation process, influence on battery performance, large internal resistance of materials, etc., so as to increase the reaction activity and improve the structural stability. , the effect of increasing the capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

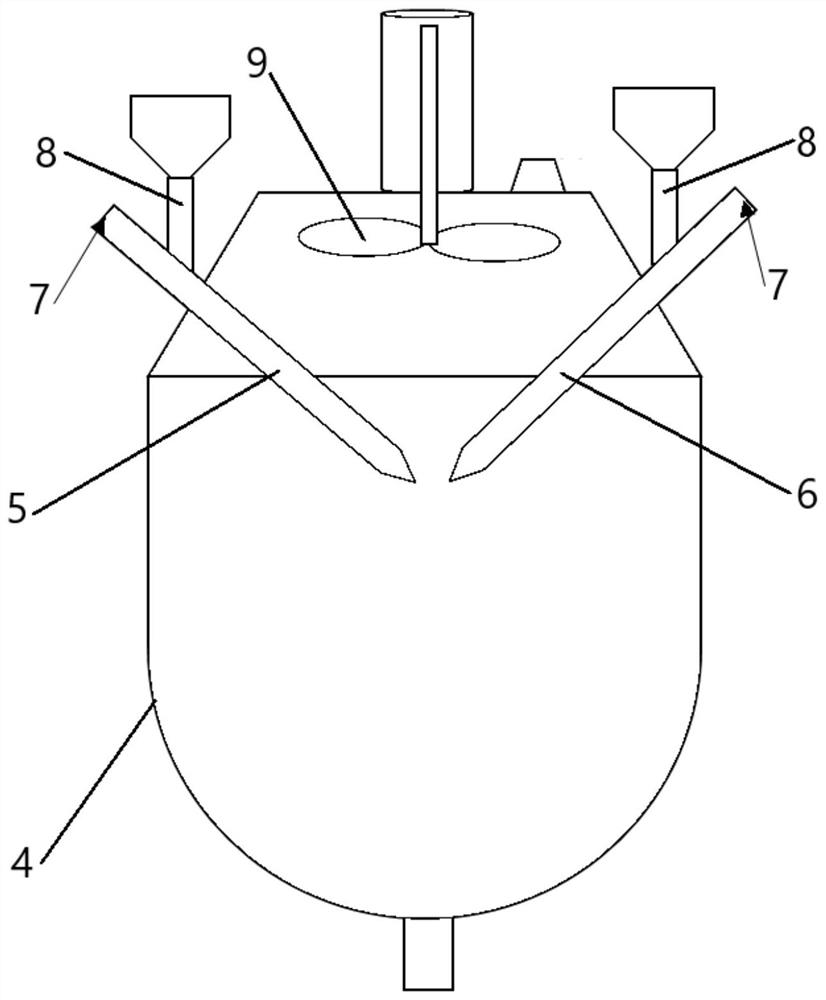

[0068] In a specific embodiment, the present invention provides a coating device, such as image 3 As shown, the coating device includes a casing 4, and the top of the casing 4 is provided with a first feeding port 5 and a second feeding port 6 opposite and inclined at the top. The first feeding port 5 and the second feeding port 6 The feeding ports 6 are all externally connected with a feeding pipe 8, and the feeding pipe 8 is externally connected with an air intake branch pipe 7; the inner top of the casing 4 is also provided with a cyclone 9; the coating device is used for positive electrode compounding The graphene 3 coating step in the preparation method of the material.

[0069] Exemplarily, a method for coating the graphene 3 and the positive electrode material 2 by the above-mentioned coating device is provided, and the method specifically includes:

[0070] The positive electrode material 2 and the graphene 3 solid powder are blown into the housing 4 with nitrogen th...

Embodiment 1

[0072] This embodiment provides a preparation method of a positive electrode composite material, and the preparation method specifically includes the following steps:

[0073] (I) Weigh the precursor of the positive electrode material 2 and the catalytic material with a mass ratio of 100:1.5. The average particle size of the precursor of the catalytic material is 0.6 μm. After mechanical stirring for 20 minutes, calcined at 600 °C for 5 hours to prepare the catalytic material. Coated positive electrode material 2;

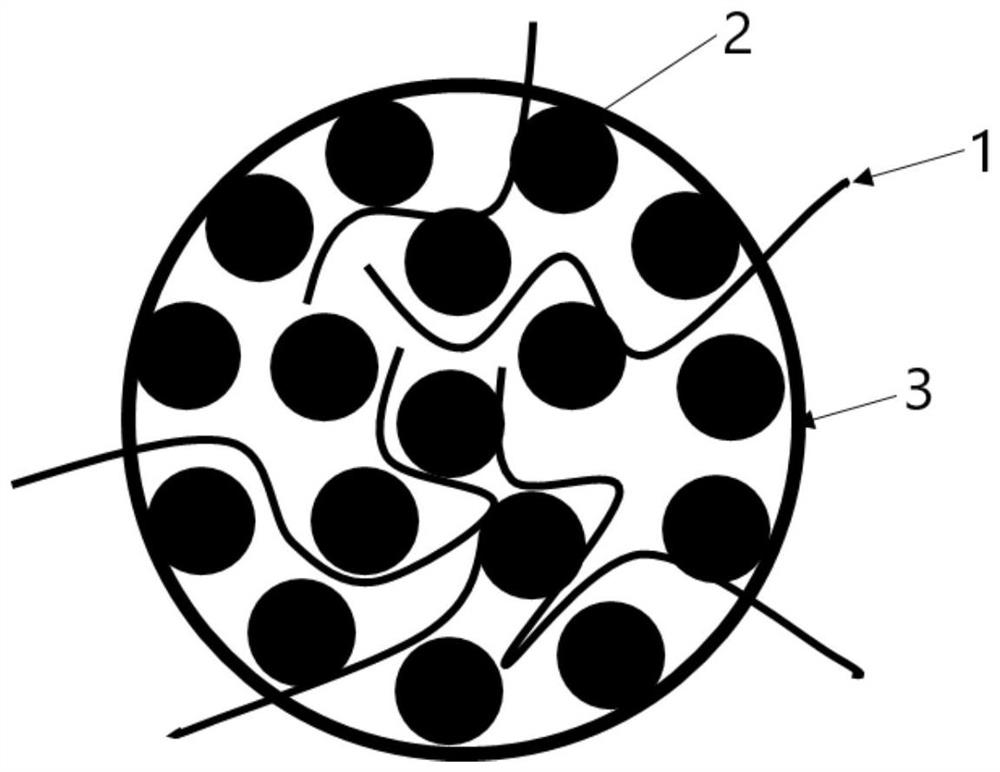

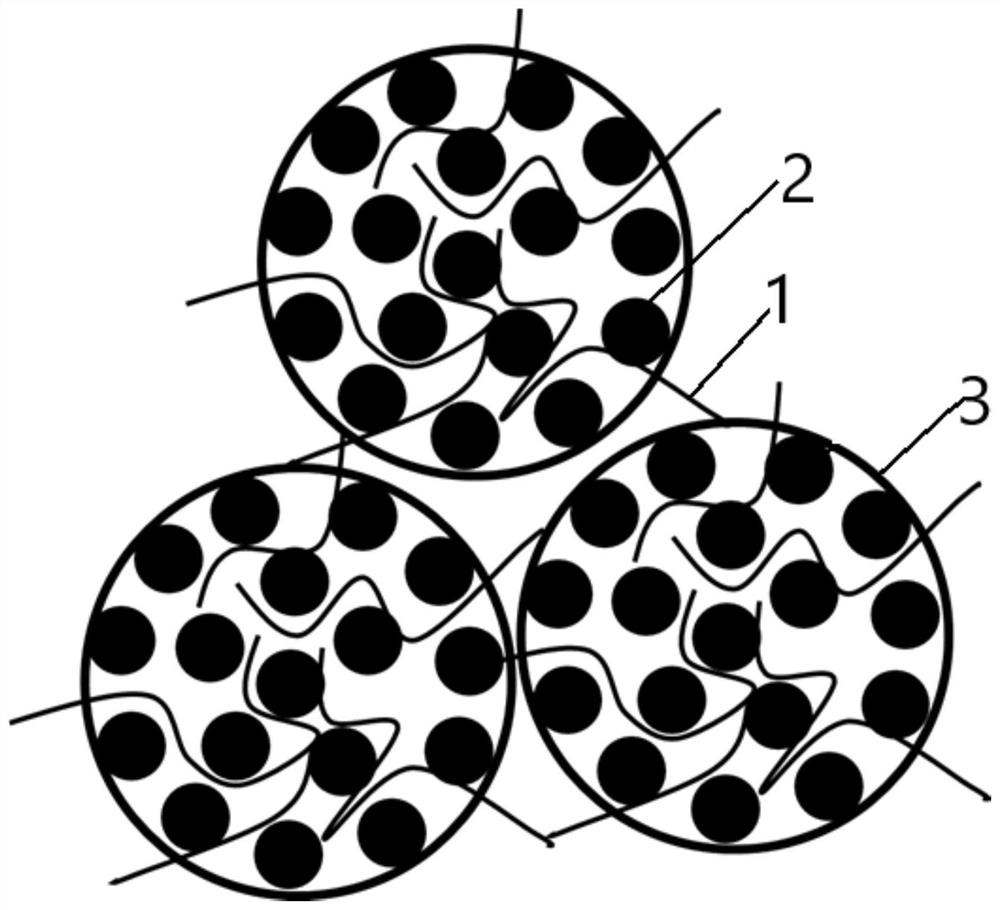

[0074](II) The cathode material 2 coated with the catalytic material in step (I) is heated for 2 hours in a carbon source gas atmosphere, the heating temperature is 700°C, and the carbon source gas atmosphere includes a carbon source gas and protective The carbon nanotubes 1 are formed on the positive electrode material 2, and the carbon nanotubes 1 are formed on the positive electrode material 2. At 190 ° C, after cyclone stirring and coating with graphene 3 with ...

Embodiment 2

[0077] This embodiment provides a preparation method of a positive electrode composite material, and the preparation method specifically includes the following steps:

[0078] (I) Weigh the precursor of the positive electrode material 2 and the catalytic material with a mass ratio of 100:1. The average particle size of the precursor of the catalytic material is 0.2 μm. After mechanical stirring for 15 minutes, calcined at 550 ° C for 6 hours to prepare the catalytic material Coated positive electrode material 2;

[0079] (II) The cathode material 2 coated with the catalytic material in step (I) is heated for 1.5 hours in a carbon source gas atmosphere, and the heating temperature is 750° C. The carbon source gas atmosphere includes carbon source gas and a volume ratio of 1:12. Protective gas, carbon source gas generates carbon nanotubes 1 on the positive electrode material 2, and at 180 ° C, after cyclone stirring and coating with graphene 3 with a transverse sheet diameter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com