Production method of special aluminum foil for solid-state capacitor

A production method and capacitor technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of increased capacitor cost, large leakage voltage, poor quality, etc., and can improve the temperature of the roaster, improve the hydration resistance, and the hydration resistance time. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

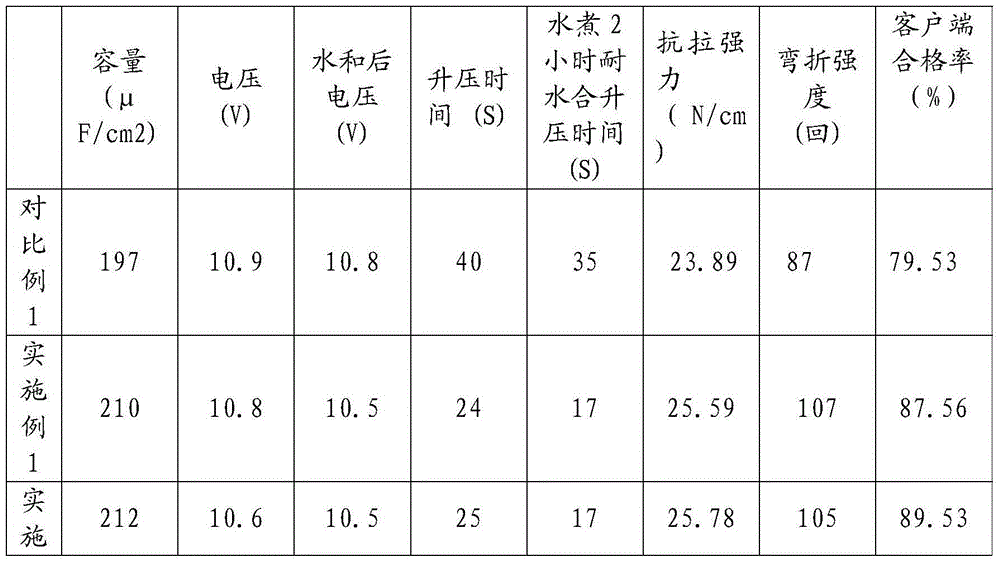

Embodiment 1

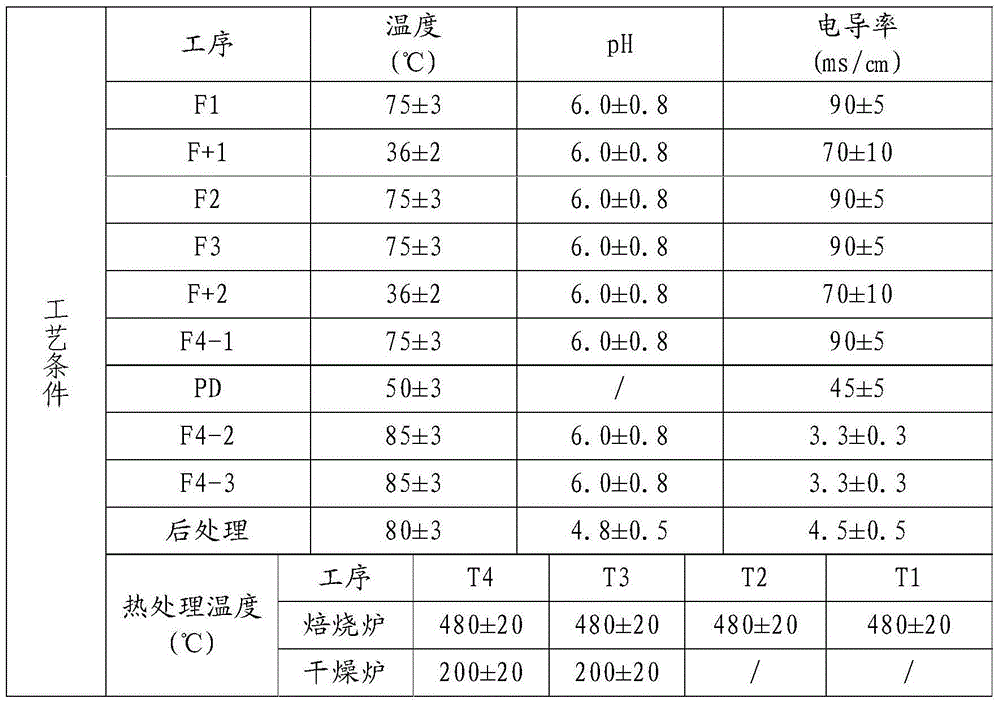

[0028] A method for producing aluminum foil for solid capacitors, comprising the steps of:

[0029] 1) Primary chemical conversion treatment (F1): Add aluminum foil to ammonium adipate solution with a concentration of 63% for chemical conversion treatment. ±2V, the current is 800±200A, the formation time is 4 minutes, and the first-grade aluminum foil is obtained;

[0030] 2) Secondary chemical conversion treatment (F+1): Add the primary chemically formed aluminum foil to the ammonium adipate solution with a concentration of 63% to carry out the chemical conversion treatment by means of power supply in the liquid. The controlled temperature is 34°C, the pH is 5.2, and the conductivity The rate is 70±10ms / ㎝, the voltage is 22±3V, the current is 600±200A, and the formation time is 4 minutes, and the secondary formation aluminum foil is obtained;

[0031] 3) Three-stage chemical conversion treatment (F3): add two-stage chemical-formation aluminum foil into ammonium adipate solut...

Embodiment 2

[0046] A method for producing aluminum foil for solid capacitors, comprising the steps of:

[0047] 1) Primary chemical conversion treatment (F1): add aluminum foil to ammonium adipate solution with a concentration of 63% for chemical conversion treatment, control the temperature at 75°C, pH at 6.0, conductivity at 90±5ms / cm, and voltage at 10 ±2V, the current is 800±200A, the formation time is 4 minutes, and the first-grade aluminum foil is obtained;

[0048] 2) Secondary chemical conversion treatment (F+1): Add the primary chemically formed aluminum foil to the ammonium adipate solution with a concentration of 63% to carry out the chemical conversion treatment by means of power supply in the liquid. The controlled temperature is 36°C, the pH is 6.0, and the conductivity The rate is 70±10ms / ㎝, the voltage is 22±3V, the current is 600±200A, and the formation time is 4 minutes, and the secondary formation aluminum foil is obtained;

[0049]3) Three-stage chemical conversion tr...

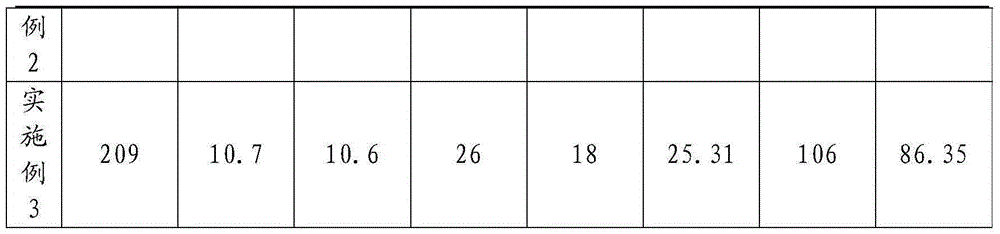

Embodiment 3

[0064] A method for producing aluminum foil for solid capacitors, comprising the steps of:

[0065] 1) Primary chemical conversion treatment (F1): Add aluminum foil to ammonium adipate solution with a concentration of 63% for chemical conversion treatment. ±2V, the current is 800±200A, the formation time is 4 minutes, and the first-grade aluminum foil is obtained;

[0066] 2) Secondary chemical conversion treatment (F+1): Add the primary chemically formed aluminum foil to the ammonium adipate solution with a concentration of 63% to carry out the chemical conversion treatment by means of power supply in the liquid. The controlled temperature is 38°C, the pH is 6.8, and the conductivity The rate is 70±10ms / ㎝, the voltage is 22±3V, the current is 600±200A, and the formation time is 4 minutes, and the secondary formation aluminum foil is obtained;

[0067] 3) Three-stage chemical conversion treatment (F3): add two-stage chemical-formation aluminum foil to ammonium adipate solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com