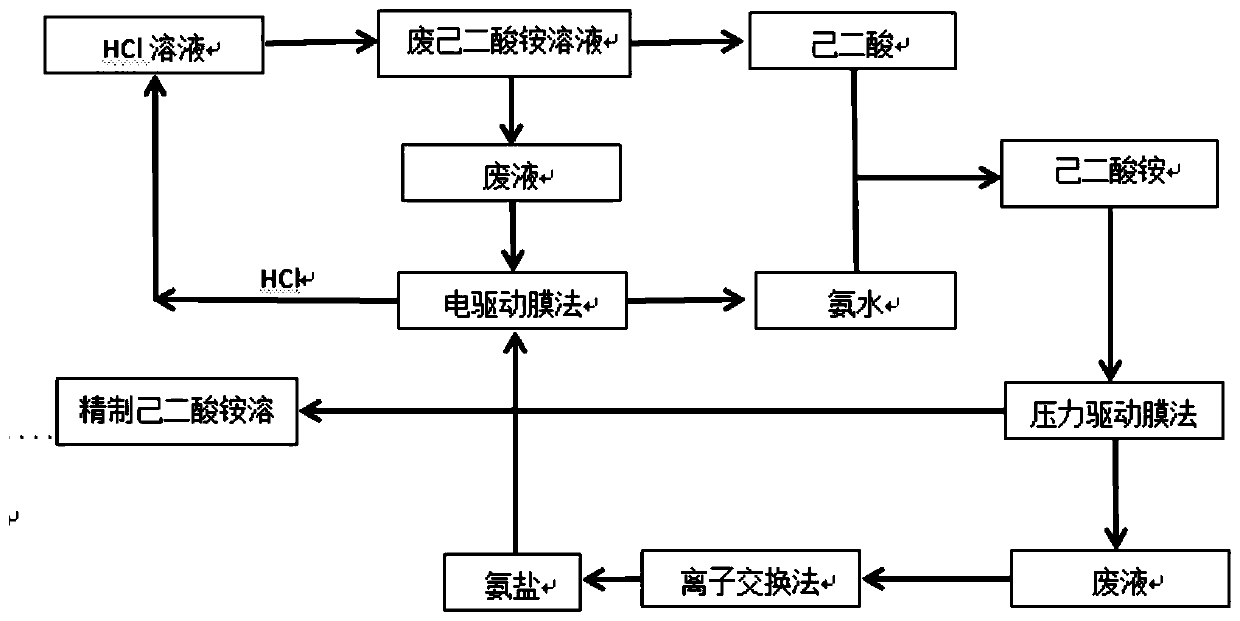

Zero-discharge treatment method for recycling and utilization of aluminum foil formation ammonium adipate wastewater

An ammonium adipate and recycling technology, applied in the field of capacitor aluminum foil production, can solve the problems of waste water discharge process, complexity, and inability to achieve low-cost zero-discharge, etc., to achieve the effect of zero-discharge treatment for recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0021] This process was used to treat the ammonium adipate waste liquid of an aluminum foil company's chemical production line, and the concentration of ammonium adipate was about 0.5mol.L through detection -1 , first add ammonia water to adjust the pH value between 6.5 and 8.0, stir to precipitate alumina and filter through a 2-micron PP cotton core to reduce the concentration of aluminum ions in the waste liquid, and then add 1mol.L to the ammonium adipate waste liquid -1 The HCl solution was stirred while adding a small amount of adipic acid crystals as seeds. Then, adipic acid is separated by filtration, and the waste liquid is processed by bipolar membrane electrodialysis, and the concentration of HC obtained by bipolar membrane electrodialysis treatment is 0.45mol.L -1 , In addition, react the obtained ammonia water with adipic acid to obtain ammonium adipate, dissolve the obtained ammonium adipate and use diffusion dialysis to purify, the flow intensity is 10L / (h m 2 )...

Embodiment example 2

[0023] This process was used to treat the ammonium adipate waste liquid of an aluminum foil company's chemical production line, and the concentration of ammonium adipate was about 0.4mol.L through detection. -1 , first add ammonia water to adjust the pH value between 6.5 and 8.0, stir to precipitate alumina and filter through a 2-micron PP cotton core to reduce the concentration of aluminum ions in the waste liquid, and then add 0.5mol.L to the ammonium adipate waste liquid -1 The HCl solution was stirred while adding a small amount of adipic acid crystals. Then adipic acid is separated by filtration, and the waste liquid is processed by bipolar membrane electrodialysis, and the concentration of HC obtained by bipolar membrane electrodialysis treatment is 0.35mol.L -1 , In addition, react the obtained ammonia water with adipic acid to obtain ammonium adipate, dissolve the obtained ammonium adipate and use diffusion dialysis to purify, the flow intensity is 10L / (h m 2 ), initi...

Embodiment example 3

[0025] This process was used to treat the ammonium adipate waste liquid of an aluminum foil company's chemical production line, and the concentration of ammonium adipate was about 0.65mol.L through detection. -1 , first add ammonia water to adjust the pH value between 6.5 and 8.0, stir to precipitate alumina and filter through a 2-micron PP cotton core to reduce the concentration of aluminum ions in the waste liquid, and then add 1mol.L to the ammonium adipate waste liquid -1 The HCl solution was stirred while adding a small amount of adipic acid crystals. Then adipic acid is separated by filtration, and the waste liquid produced is treated by bipolar membrane electrodialysis, and the concentration of HC obtained by bipolar membrane electrodialysis treatment is 0.5mol.L -1 , In addition, the obtained ammonia water and adipic acid are reacted to obtain ammonium adipate, and after the obtained ammonium adipate is dissolved, the diffusion dialysis method is used for purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com