Preparation method of electrolyte for capacitor, electrolyte and application thereof

An electrolyte and capacitor technology, applied in the field of electrolyte, can solve the problems of high frequency, low impedance, low leakage, long life, short storage life, large leakage current of capacitors, etc. High rate, inhibiting hydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

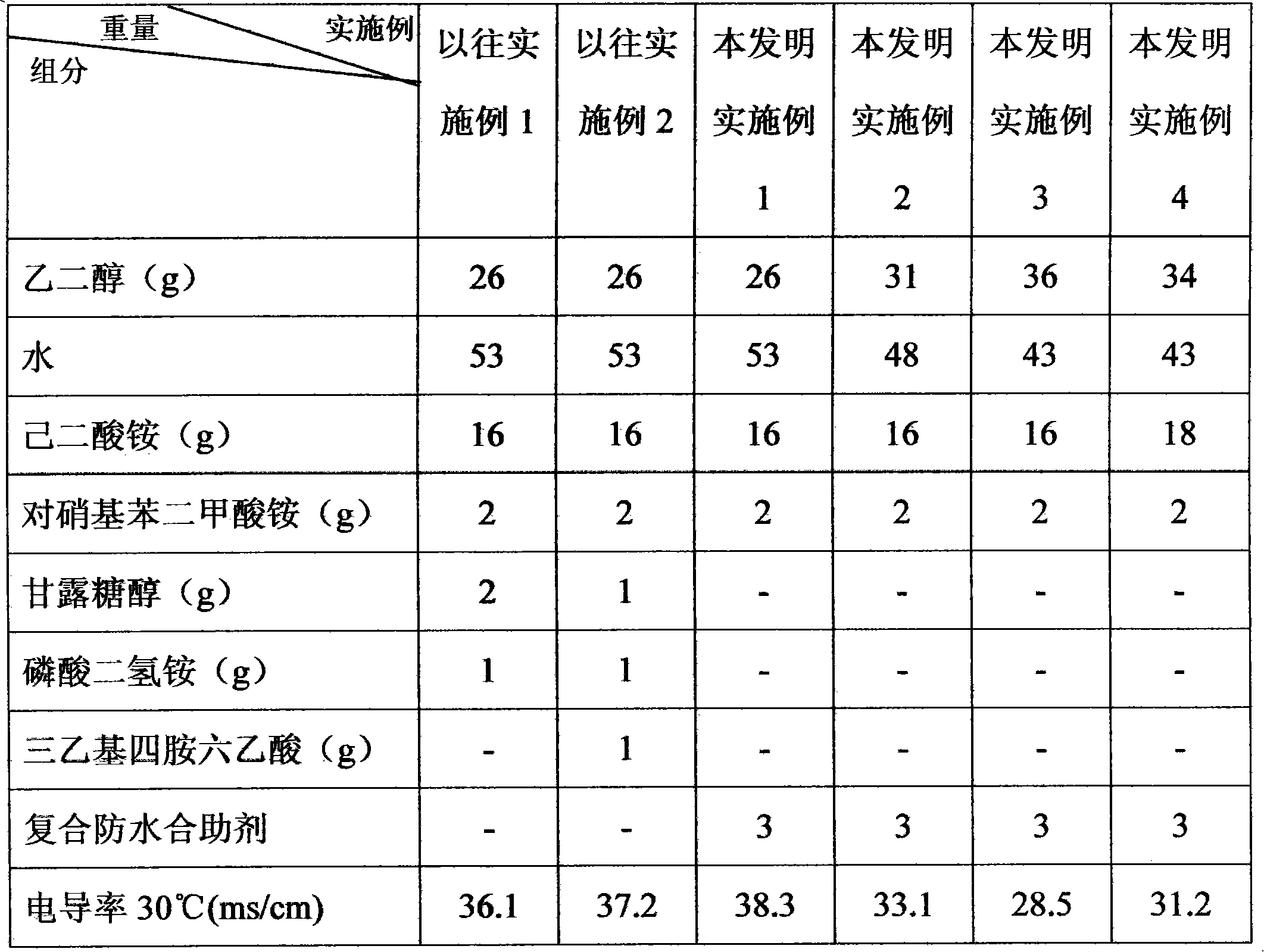

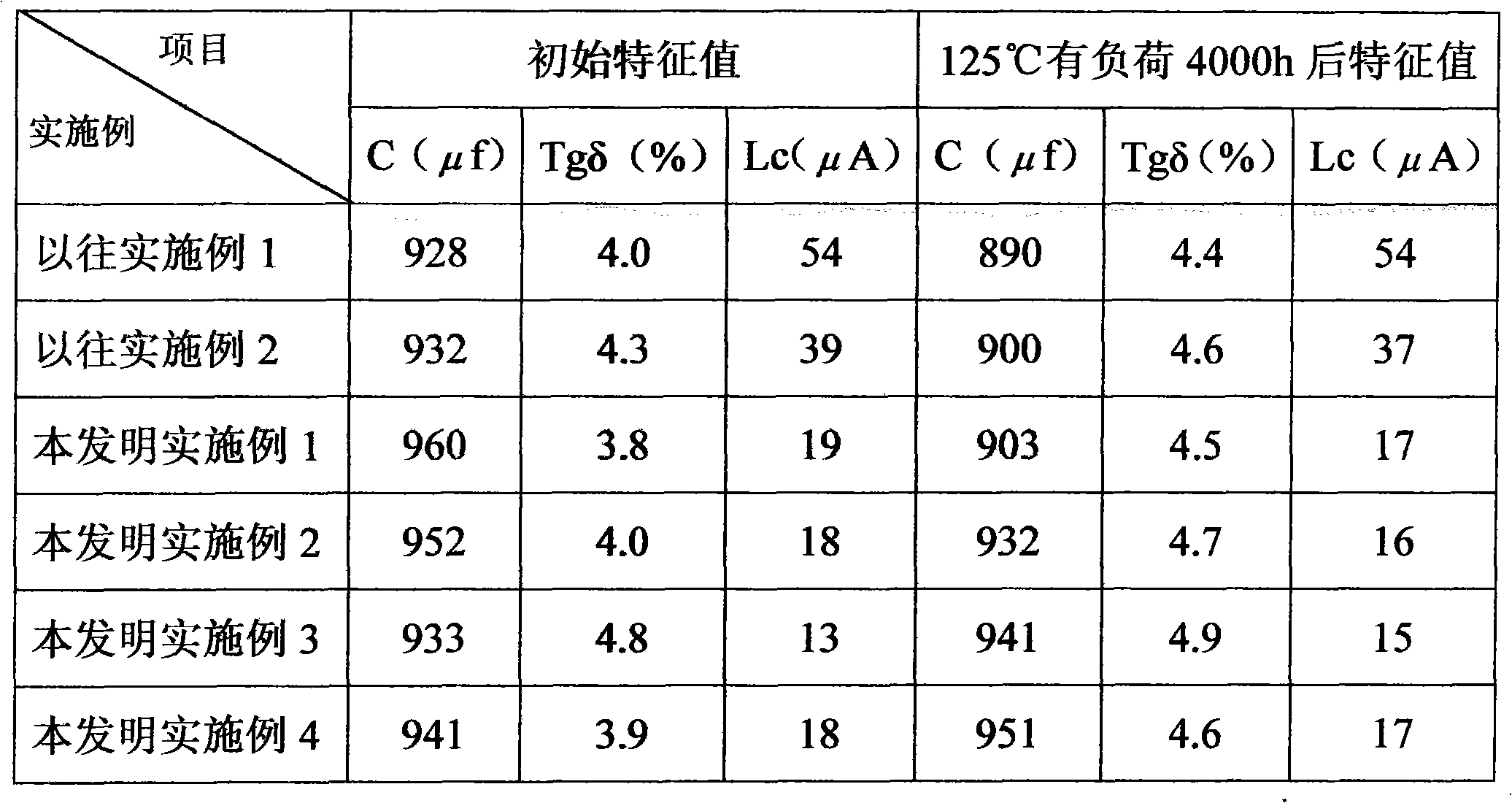

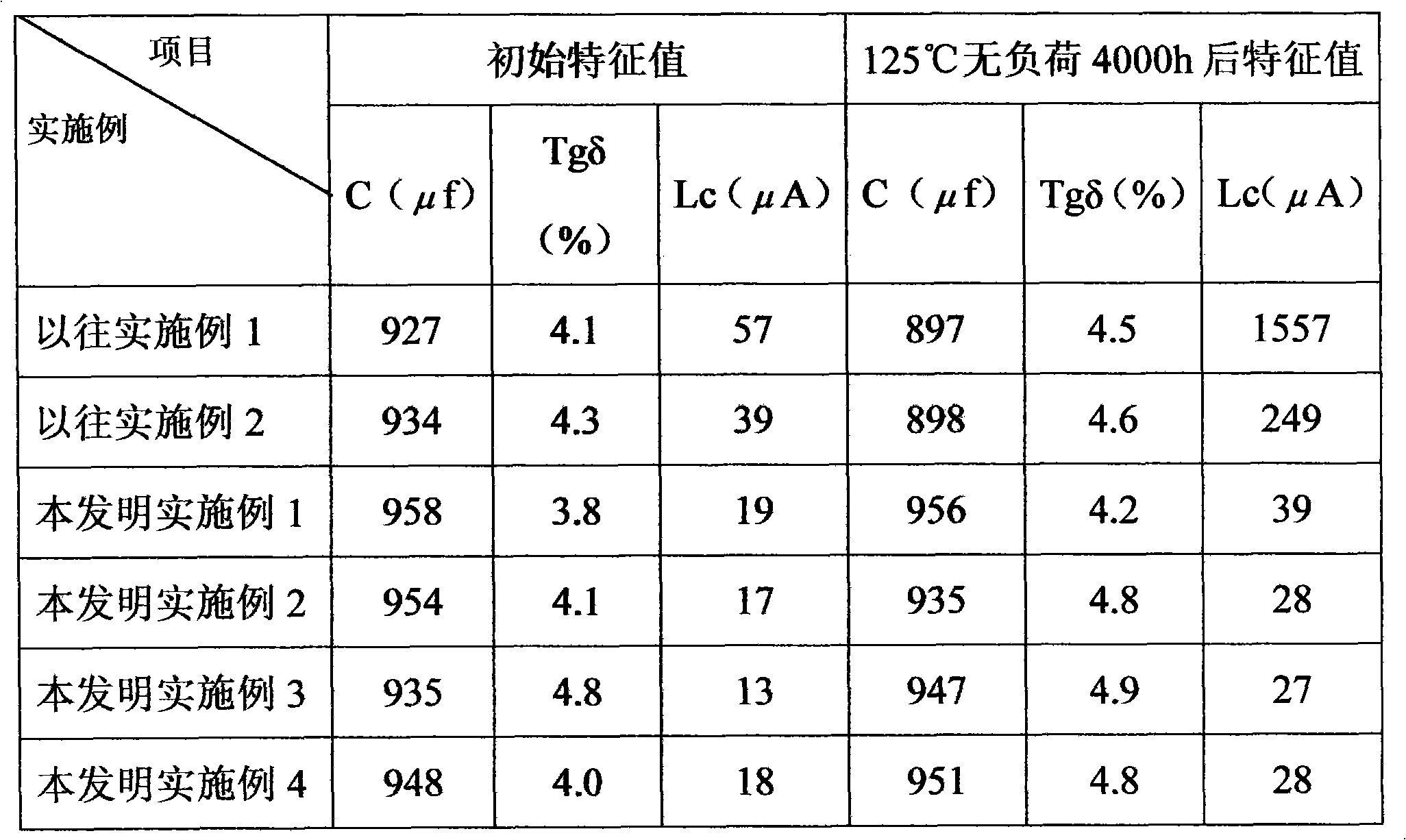

[0037] A preparation method for an electrolyte for a low-voltage electrolytic capacitor, comprising the following process steps:

[0038] (1) Weigh the raw materials according to the formula given in Example 1-4 in Table 1, and prepare the electrolyte according to the following steps (2)-(4) respectively;

[0039] (2) Feeding: Add ethylene glycol, water, ammonium adipate, ammonium p-nitrobenzoate, and water-repellent adjuvants in sequence in the liquid mixing pot;

[0040] (3) Dissolving: heating, controlling the temperature to be 50-60°C, and stirring for 1-2 hours to dissolve the compound added in step (1);

[0041] (4) Adjusting PH: cooling the completely dissolved compound in step (2) to 30-40° C., adjusting the pH value to 6.5-7.0 with ammonia gas or ammonia water, and discharging to obtain an electrolyte for low-voltage electrolytic capacitors.

[0042] The present invention uses a composite waterproofing auxiliary agent containing phosphorus, polyhydric alcohols and am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com