Method for low-pressure soft-state corrosion of aluminum foil

A technology of corroding aluminum foil and soft state, which is applied in the field of corroding foil electrodes, can solve the problems of low cost, inability to use for a long time, nitrogen and phosphorus emissions, etc., and achieve the effects of low cost, environmental protection and reduction of nitrogen and phosphorus emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

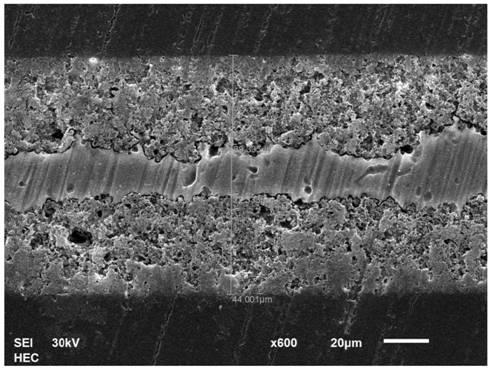

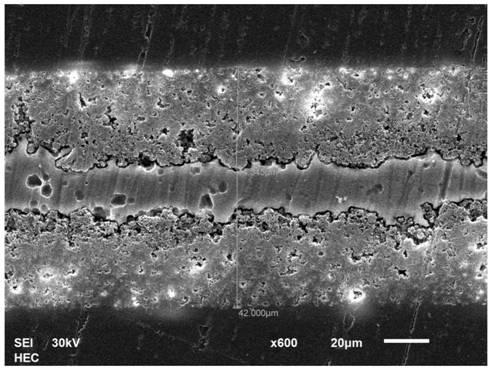

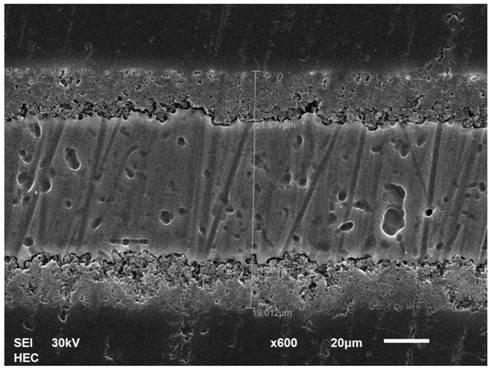

Image

Examples

Embodiment 1

[0047] A method for low-pressure soft-state corrosion of aluminum foil, comprising the steps of:

[0048] S1. Prepare an aluminum foil, and perform degreasing treatment for 1 min in phosphoric acid or nitric acid with a temperature of 60-80° C. and a concentration of 1 wt % to 15 wt %. Specifically, in this embodiment, the aluminum foil is a 105 micron low-voltage light foil, and the sample area is 5.5 cm×13 cm; the acid solution is specifically phosphoric acid, the temperature is 70° C., and the concentration is 1.5 wt%.

[0049] S2. Electrochemical corrosion: In the mixed solution of 3wt%~15wt% hydrochloric acid and 0.001wt%~2wt% sulfuric acid, use alternating current and specific frequency to conduct galvanic corrosion, and the current density is 0.05~0.3A / cm 2 , wash with water after the corrosion is completed. Specifically, in this embodiment, in a mixed solution of 10wt% hydrochloric acid and 0.02wt% sulfuric acid, the current density is 0.25A / cm 2 , Corrosion time 60s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com