Electrolyte of wide-temperature aluminium electrolytic capacitor and manufacturing method thereof

A technology for aluminum electrolytic capacitors and manufacturing methods, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve problems such as large loss value, poor stability, blasting, etc., achieve great social and economic benefits, stable performance, and save foreign exchange.

Inactive Publication Date: 2010-08-25

HENGYANG CHUANGJI ELECTRONICS

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current production of wide temperature aluminum electrolytic capacitors has a working environment temperature in the range of -40°C to 105°C. When the working temperature exceeds 105°C, the leakage current of the capacitor increases rapidly, the air pressure in the aluminum shell increases, and even explodes and fails. The main reason is that the electrolyte solution of the current wide temperature aluminum electrolytic capacitor has poor stability, large loss value and high leakage current in a high temperature environment above 105 °C.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

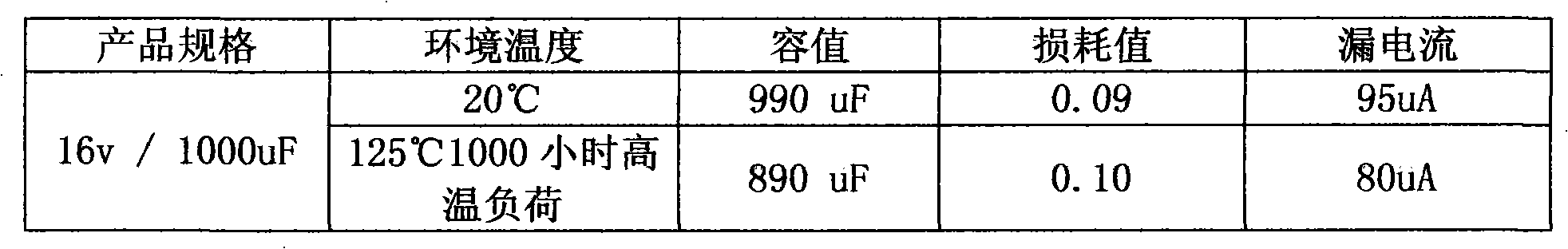

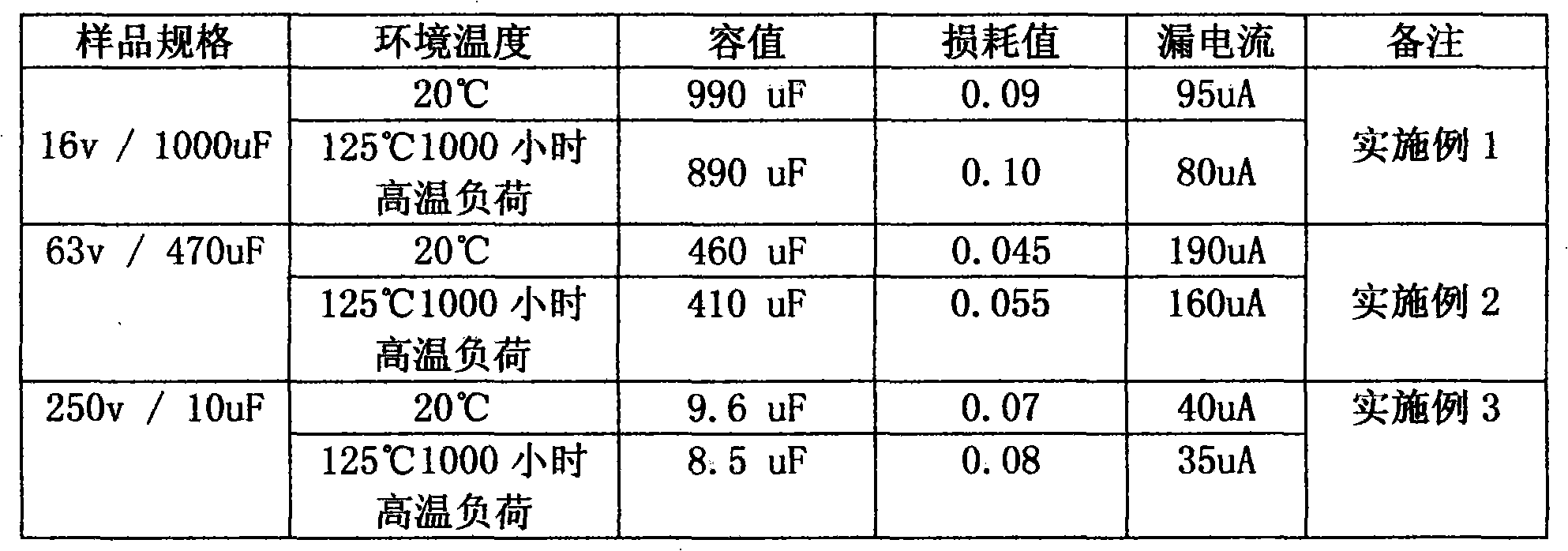

Embodiment 1

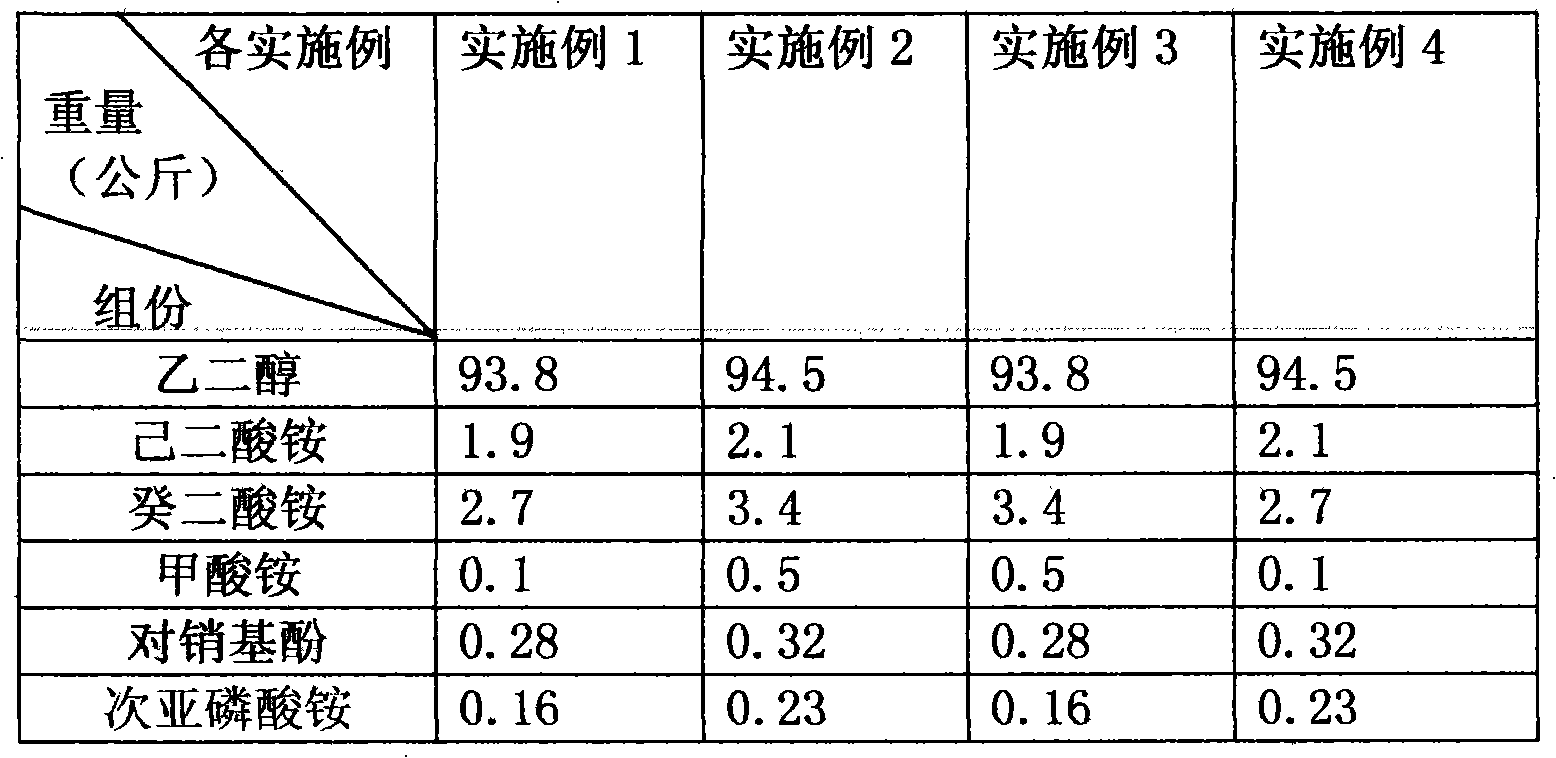

Embodiment 2、 Embodiment 3、 Embodiment 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a manufacturing method for electrolyte of a wide-temperature aluminium electrolytic capacitor, comprising the raw materials of ethanediol, ammonium adipate, ammonium sebacate, ammonium formate, p-nitrophenol and ammonium hypophosphite. The method comprises the following steps of heating the ethanediol in parts by weight to 50-60 DEG C, adding the other raw materials in parts by weight in the ethanediol, heating to 130-135 DEG C while stirring, maintaining the constant temperature of 130-135 DEG C for 20-30min, and cooling to the room temperature to prepare the electrolyte of the wide-temperature aluminium electrolytic capacitor. The invention is mainly applied in electric products, electricity control systems, multifunctional meters, power supply parts of computers, various home appliances and other fields. The aluminium electrolytic capacitor prepared from the electrolyte obtained in the invention can produce no high atmospheric pressure and has stable performance in the environment with the temperature no more than 125 DEG C.

Description

technical field The invention relates to an electrolytic solution of an electrolytic capacitor and a manufacturing method thereof, in particular to an electrolytic solution of a wide-temperature aluminum electrolytic capacitor and a manufacturing method thereof. Background technique The current production of wide temperature aluminum electrolytic capacitors has a working environment temperature in the range of -40°C to 105°C. When the working temperature exceeds 105°C, the leakage current of the capacitor increases rapidly, the air pressure in the aluminum shell increases, and even explodes and fails. The main reason is that the electrolyte solution of the current wide temperature aluminum electrolytic capacitor has poor stability, large loss value and high leakage current in a high temperature environment above 105 °C. Contents of the invention The object of the present invention is to overcome the above-mentioned deficiencies of the prior art and provide a kind of elect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G9/035

Inventor 陈继芳

Owner HENGYANG CHUANGJI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com