A suspension device and method for controlling release by using hydraulic pressure difference

A technology for controlling release and suspension devices, applied in the field of drilling, which can solve problems such as increased chance of rework, polluted wellhead, unrecoverable steel balls, etc., and achieves the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

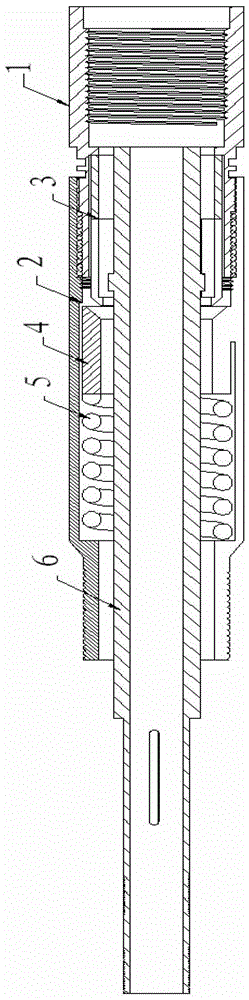

[0018] Such as figure 1 As shown, a suspension device controlled and released by hydraulic pressure difference is composed of upper joint 1, device body 2, slips 3, differential pressure sliding sleeve 4, spring 5, and load bearing joint 6, upper joint 1 and device body 2. The tubing buckle is connected by the tubing buckle. The slip 3 is nested in the upper joint 1, the differential pressure sliding sleeve 4 and the spring 5 are nested in the device body 2, and the outer diameter of the bearing joint 6 is connected with pressure Differential sliding sleeve 4, spring 5, bearing joint 6 are positioned and suspended at slip 3, and the design suspension weight is 30KN;

[0019] The outer diameters of the upper joint 1 and the device body 2 are both φ95mm or greater than φ95mm;

[0020] The upper joint 1 and the device body 2 are connected by a φ73mm tubing buckle, or a tubing buckle larger than φ73mm;

[0021] The outer diameter of the bearing connector 6 is φ46mm or greater than φ46m...

Embodiment 2

[0024] A controlled release method using hydraulic pressure difference, including the following steps:

[0025] After the downhole tool is connected to the suspension device controlled and released by hydraulic pressure difference, the suspension device released by hydraulic pressure difference control is lowered into the predetermined position in the well, and the workover fluid is pumped from the tubing. When the pressure difference reaches 3-4Mpa, the pressure When the differential sliding sleeve 4 goes down and the driving force of the differential sliding sleeve 4 exceeds the starting force of the spring 5, the differential sliding sleeve 4 moves down to the supporting surface that is separated from the supporting slips. At this time, the slips 3 are opened, and the bearing joint 6 is in contact with the phase. The connecting tools are released and dropped together to achieve the expected purpose. The differential pressure sliding sleeve 4 is automatically returned to the pos...

Embodiment 3

[0029] A suspension device that uses hydraulic pressure difference to control and release is composed of upper joint 1, device body 2, slips 3, differential pressure sliding sleeve 4, spring 5, and load bearing joint 6. The outer diameters of upper joint 1 and device body 2 Both are φ95mm. The upper joint 1 and the device body 2 are connected by a φ73mm tubing buckle through a connecting thread. The bearing joint 6 has an outer diameter of φ46mm and an inner diameter of φ28mm. The slip 3 is nested in the upper joint 1, the differential pressure sliding sleeve 4, spring 5 It is nested in the device body 2, the diameter of the device body 2 is φ52mm, the bearing joint 6 is positioned and hung at the slip 3, and the design suspension weight is 30KN.

[0030] The slip 3 is connected to the upper joint 1 in a rotary movable connection.

[0031] A differential pressure sliding sleeve 4 and a spring 5 are nested inside the body 2 of the device. One side of the differential pressure slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com