Polyetheretherketone hollow fiber preparation method

A polyetheretherketone and polyetheretherketone resin technology is applied in the field of preparation of polyetheretherketone hollow fibers, which can solve the problem that the uniformity of hollowness of hollow fibers cannot be completely guaranteed, and the consistency of hollow fibers cannot be fully guaranteed. It can completely guarantee and easily destroy the hollow shape of the hollow fiber, and achieve the effect of reducing surface defects, good uniformity and wear resistance, and perfect crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

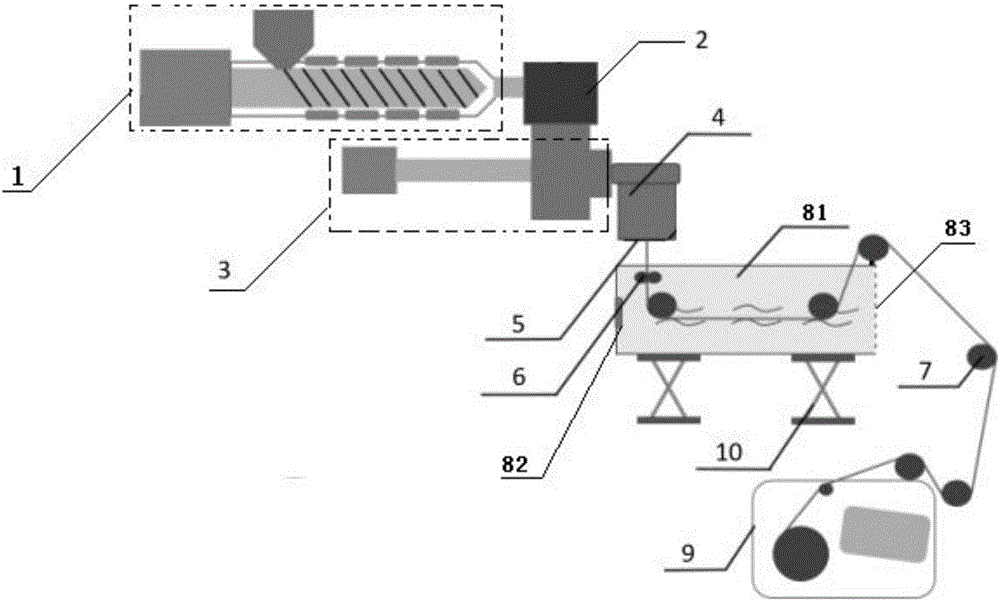

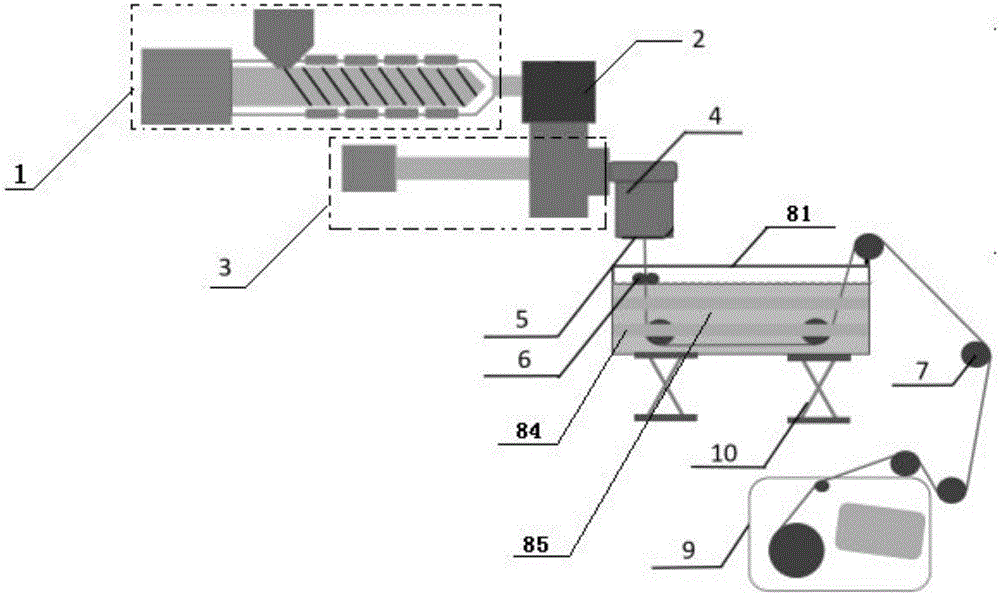

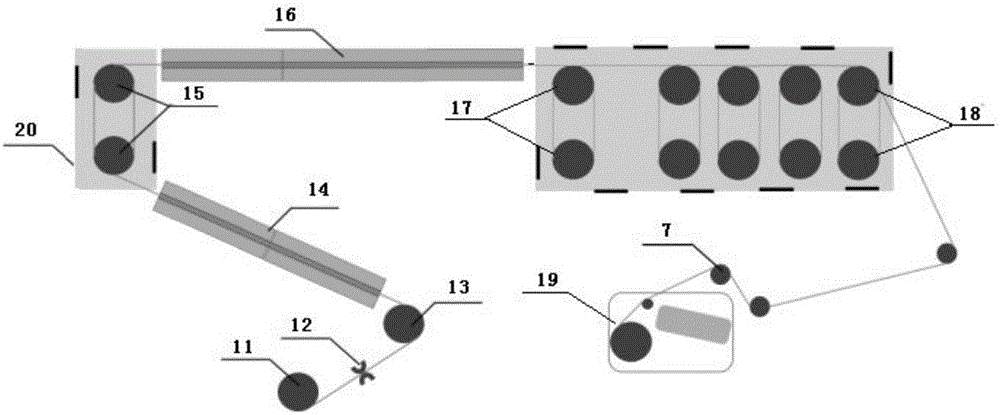

[0046] Such as Figure 1-3 Shown, a kind of preparation method of polyether ether ketone hollow fiber, the steps are as follows:

[0047] Step 1. Dry the special material for spinning grade polyetheretherketone resin. The drying temperature is 100-160°C and the time is 2-12 hours. After drying, add it to extruder 1. Melt in the temperature range of 280-430°C to obtain a melt, which is transported to the metering pump box 3 through the melt pipeline 2, and the metering pump 31 in the metering pump box 3 is accurately metered and output to the spinning machine under constant pressure conditions. The amount of melt in the component 4, and the melt is sent to the spinning component 4, the melt is in the spinning component 4, first filtered through the filter system, and then spun through the hollow spinneret 5 to obtain the polyether ether ketone hollow fiber Melt strips.

[0048] In step one, the special material for spinning grade polyether ether ketone resin is the prior art ...

Embodiment 1

[0064] Step 1. Dry the spinning-grade polyether ether ketone resin special material (99wt% PEEK pure resin and 1wt% high-temperature lubricant). The drying temperature is 160°C and the time is 5h. In the machine 1, the melt is obtained, and the melt is transported to the metering pump box 3 through the melt pipeline 2, and the metering pump 31 in the metering pump box 3 (gear metering pump, its working temperature can reach 500 ℃, and the nominal output The amount is 0.6cc / r,) the melt is output to the spinning assembly 4 at an output speed of 14r / min under 10MPa, and the heating temperatures from the feed port of the extruder 1 to the front of the metering pump 31 are 280°C, 340°C, and 380°C respectively. ℃, 390°C, 393°C, the pressure of the spinning assembly is 13-15MPa, and the temperature is 403°C. The melt is in the spinning assembly 4, and it is first filtered through the filter system (60-500 mesh multi-layer stainless steel mesh and 20- 200 mesh quartz sand particles),...

Embodiment 2

[0070] The output speed of the metering pump 31 is 18r / min, the specification of the hollow spinneret 5 is 12 holes, D1 is 0.8mm, D2 is 0.5mm, d1 is 0.15mm, and the pressure of the spinning assembly 4 is 16-19MPa. Cold system, the winding speed of the first winding device 9 is 10m / min, the temperature of the godet hot roller 13 is 130°C, the temperature of the first heating slit 14 is 180°C, and the temperature of the first drafting hot roller 15 is 180°C, the temperature of the second heating slit 16 is 230°C, the temperature of the second drafting hot roller 17 is 180°C, the temperature of the shaping hot roller 18 is 180°C, the draw ratio is 3.2, and the relaxation setting ratio is 0.95 : 1, other conditions are all identical with embodiment 1.

[0071] After testing, the diameter of the obtained polyether ether ketone hollow fiber is 0.188mm, the hollow rate is 52.34%, the linear density is 203.64dtex, and the fiber strength is 4.12cN / dtex. The picture of the scanning elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com