Aperture adjustable composite inorganic oxide nanopore fiber with communication pores and single-spray head electro-spinning preparation method thereof

A technology of inorganic oxides and connected pores, which is applied in fiber processing, chemical characteristics of fibers, rayon of inorganic raw materials, etc., to achieve the effect of broadening the control range, avoiding preparation conditions and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

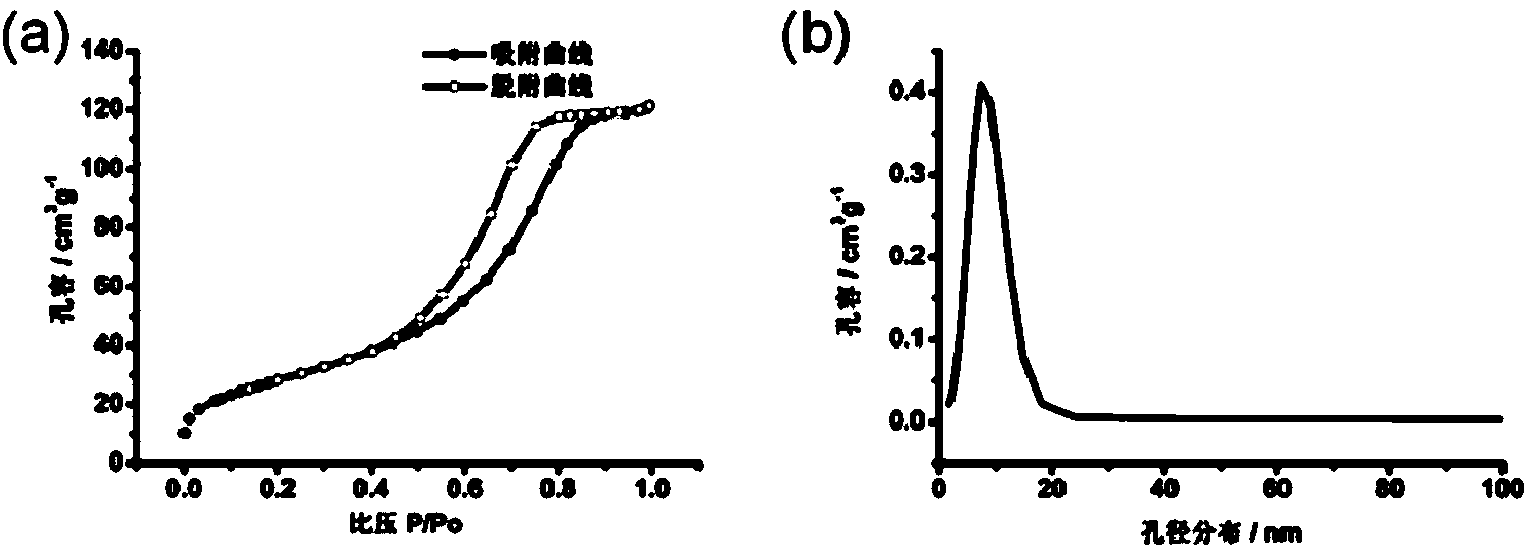

[0085] Example 1: Ti / Si-1

[0086] Mesoporous TiO 2 / SiO 2 Preparation of nanofibers:

[0087] (1) Preparation of spinning solution: at a humidity of 10% RH and a temperature of 20°C, add 2g of polyvinylpyrrolidone to a mixture of 10g of absolute ethanol and 2g of glacial acetic acid, stir until clear, and then add 5.5g of titanium Acetate tetrabutyl ester and 0.5g ethyl orthosilicate, continue to stir for 1h to obtain a viscous spinning solution.

[0088] (2) Mesoporous TiO 2 / SiO 2 Fiber spinning preparation: control the flow rate to 4ml / h, inject the electrospinning solution prepared above into a syringe equipped with a stainless steel dispensing needle with an inner diameter of 1.37mm, the spinning distance is 30cm, the electrospinning humidity is 10%RH, and the temperature is Electrospinning was carried out under the spinning conditions of 20°C and a voltage of 13KV to obtain TiO 2 / SiO 2 / PVP composite fiber, and then dried in a drying oven at 60°C for 6h, put the...

Embodiment 2

[0089] Example 2: Ti / Si-2

[0090] Mesoporous-Macroporous Secondary Porous TiO 2 / SiO 2 Preparation of nanofibers:

[0091] Similar to Example 1, when adjusting the preparation and spinning, the amount of tetrabutyl titanate added is 2.5g, the amount of tetraethyl orthosilicate is 3.5g, other conditions are similar, the flow rate is controlled at 6ml / h, and the above prepared The electrospinning solution is injected into a syringe equipped with a stainless steel dispensing needle with an inner diameter of 1.55 mm, the spinning distance is 25 cm, the electrospinning humidity is 30% RH, the temperature is 24 ° C, and the electrospinning voltage is 16 KV under the spinning conditions to obtain TiO 2 / SiO 2 / PVP composite fiber, then dried in a drying oven at 30°C for 10 hours, put the dried fiber in a muffle furnace, raised the temperature to 700°C at 5°C / min, kept it warm for 6 hours, and cooled down naturally to obtain a medium Pore-Macropore Secondary Pore TiO 2 / SiO 2 C...

Embodiment 3

[0092] Example 3: Ti / Si-3

[0093] Microporous-mesoporous-macroporous tertiary TiO 2 / SiO 2 Preparation of nanofibers:

[0094] Similar to Example 1, when adjusting the preparation and spinning, the amount of tetrabutyl titanate added is 0.5g, the amount of tetraethyl orthosilicate is 5.5g, other conditions are similar, the flow rate is controlled at 8ml / h, and the above prepared The electrospinning solution was injected into a syringe equipped with a stainless steel needle with an inner diameter of 1.23 mm, the spinning distance was 30 cm, the electrospinning humidity was 30% RH, the temperature was 30 ° C, and the electrospinning voltage was 18 KV under the spinning conditions to obtain TiO 2 / SiO 2 / Dry the PVP composite fiber in a drying oven at 60°C for 8 hours, put the dried fiber in a muffle furnace, raise the temperature to 1000°C under programmed temperature control at 20°C / min, keep it warm for 10 hours, and cool down naturally to obtain micropores- Mesoporous-Ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com