Bidirectional compression die, and implementation method and application thereof

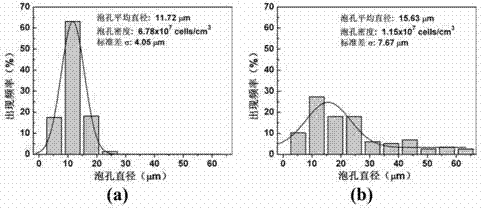

A technology of lateral compression and longitudinal compression, applied in the field of molds, can solve the problems of unsatisfactory control of microcellular foaming, and achieve the effects of good interchangeability, compact and reasonable overall structure, large flexibility and scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

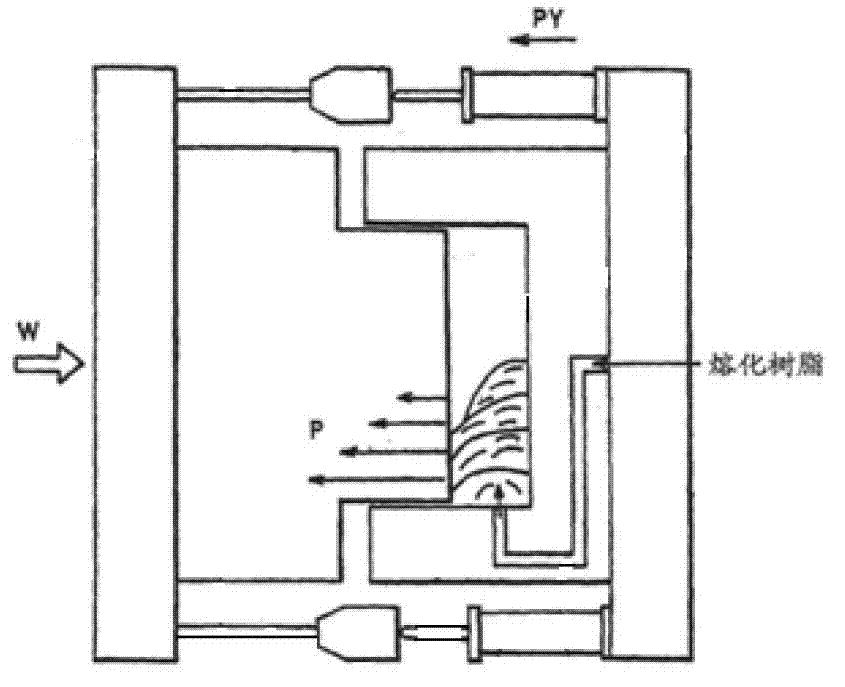

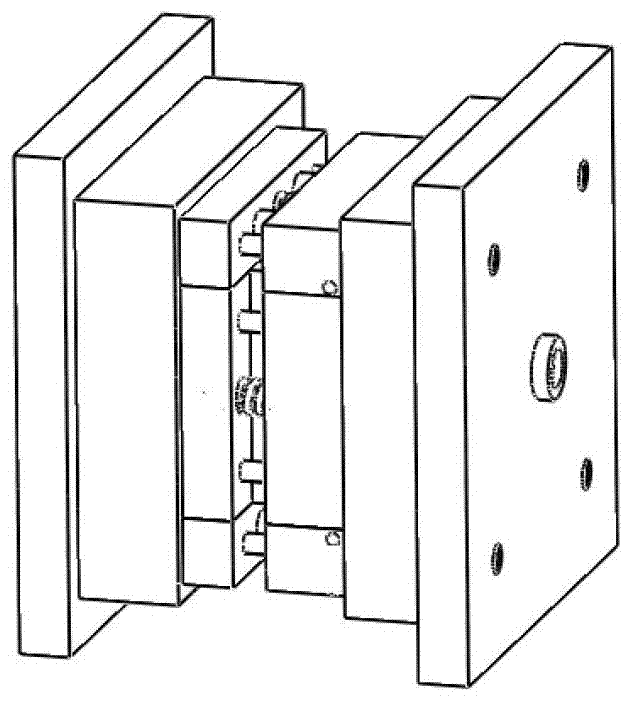

[0048] Figure 2 ~ Figure 4 shows the concrete structure of the present invention, by Figure 2 ~ Figure 4 It can be seen that the two-way compression mold of the present invention includes a movable template 1, a movable mold fixed plate 3, a fixed template 16, a fixed mold fixed plate 15, a cavity block assembly, and a compression block assembly; the cavity block assembly includes a longitudinal cavity block ( 71, 72, 74, 141, 142 and 144) and transverse cavity blocks (73 and 143); the compression block assembly includes a longitudinal compression block 8 and a transverse compression block 9; the fixed mold fixing plate 15, cavity block Assembly and compression block assembly constitutes a closed cavity 23, and through the longitudinal cavity block (71, 72, 74, 141, 142 and 144), the longitudinal compression block 8 and the transverse cavity block (73 and 143), the transverse The relative movement of the compression block 9 in the longitudinal and transverse directions real...

Embodiment 2

[0064] The polymer product is molded according to the two-way compression method described in Example 1, but the transverse compression speed is set to zero, so that the polymer melt 27 in the mold cavity 23 is only subject to longitudinal compression.

Embodiment 3

[0066] The polymer product is molded according to the two-way compression method described in Example 1, but the longitudinal compression speed is set to zero, so that the polymer melt 27 in the mold cavity 23 is only subjected to transverse compression.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com