Macromolecule nucleating agent modified polyethylene glycol terephthalate

A technology of polyethylene terephthalate and ethylene terephthalate, which is applied in the field of polymer nucleating agent modified polyethylene terephthalate, can solve the problem of polymer crystallization. The molecular weight of the nucleating agent should not be too large, the ability to promote crystallization is weakened, and the mobility of the molecular chain is reduced, so as to achieve good dispersion, reduce crystal defects, and improve melt fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

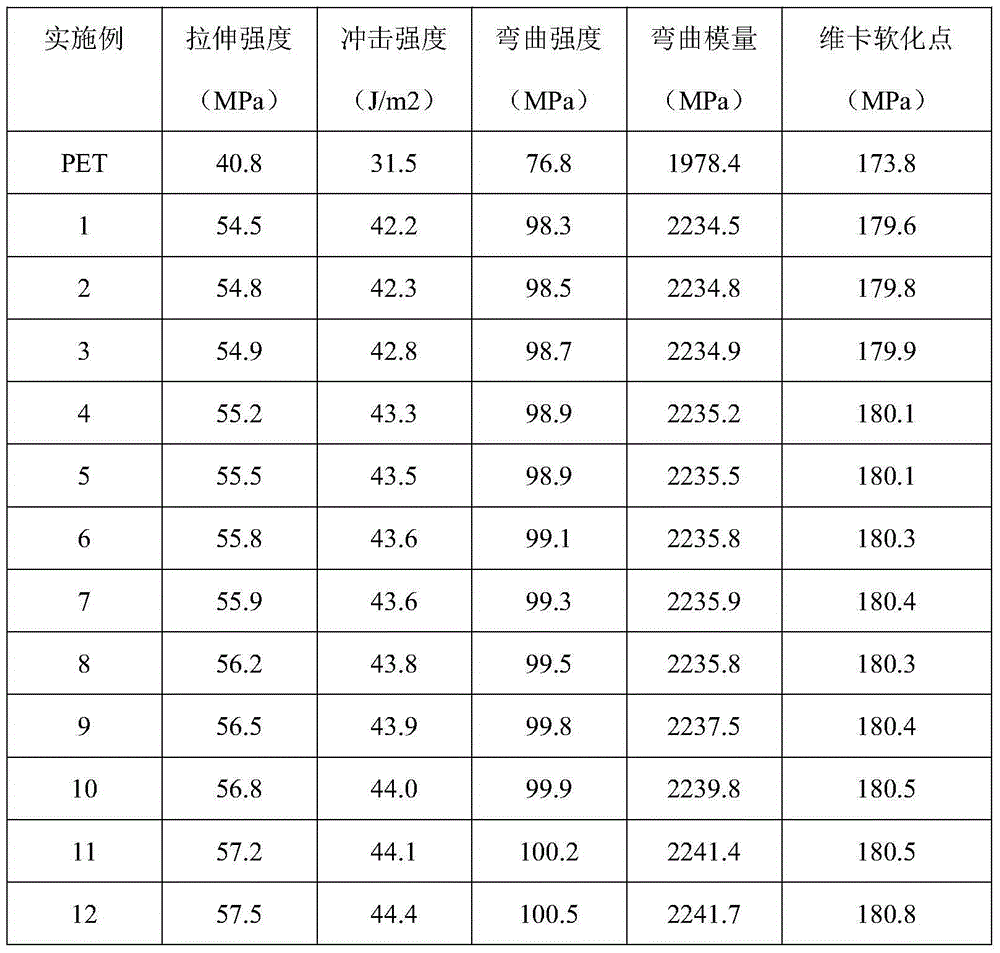

[0023] Example 1: (using polymer nucleating agent: poly-3-methylbutene-1)

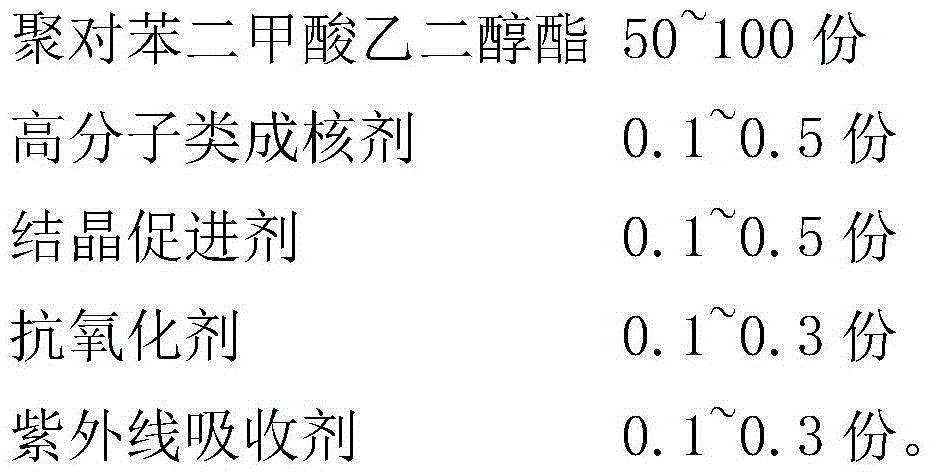

[0024] A polymer nucleating agent modified polyethylene terephthalate, comprising the following raw materials in parts by weight: PET: 50kg, polymer nucleating agent (poly-3-methylbutene-1): 0.1kg; crystallization accelerator (polyethylene glycol): 0.1kg; antioxidant DLTP: 0.1kg; ultraviolet absorber UV-P: 0.1kg.

[0025] Improve polyethylene terephthalate according to the polymeric nucleating agent described above, the preparation method comprises the following steps: (1) poly-3-methylbutene-1, polyethylene glycol, PET are respectively added Dry in an oven at 80-150°C for 4-6 hours before use;

[0026] (2) Mix poly 3-methylbutene-1 and PET evenly, then add polyethylene glycol, antioxidant DLTP and ultraviolet absorber UV-P in sequence, mix in a high-speed mixer for 2 to 8 minutes, and use a twin-screw The extruder performs melt blending extrusion granulation. The temperature setting of the extruder...

Embodiment 2-27

[0027] Embodiment 2-27, use macromolecule class nucleating agent: poly-3-methylbutene-1, the parts by weight of other raw materials that adopt is as follows: unit kg

[0028] Example 2 3 4 5 6 7 8 9 10 11 PET 50 50 50 50 50 50 50 50 80 80 poly-3-methylbutene-1 0.3 0.5 0.1 0.3 0.5 0.1 0.3 0.5 0.1 0.3 polyethylene glycol 0.1 0.1 0.3 0.3 0.3 0.5 0.5 0.5 0.1 0.1 DLTP 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.2 0.2 UV-P 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.1 0.2 0.2

[0029] Example 12 13 14 15 16 17 18 19 20 21 PET 80 80 80 80 80 80 80 100 100 100 poly-3-methylbutene-1 0.5 0.1 0.3 0.5 0.1 0.3 0.5 0.1 0.3 0.5 polyethylene glycol 0.1 0.3 0.3 0.3 0.5 0.5 0.5 0.1 0.1 0.1 DLTP 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.3 0.3 0.3 UV-P 0.2 0.2 0.2 0.2 0.2 0.2 0.2 0.3 0.3 0.3

[0030] Example 22 23 24 25 26 27...

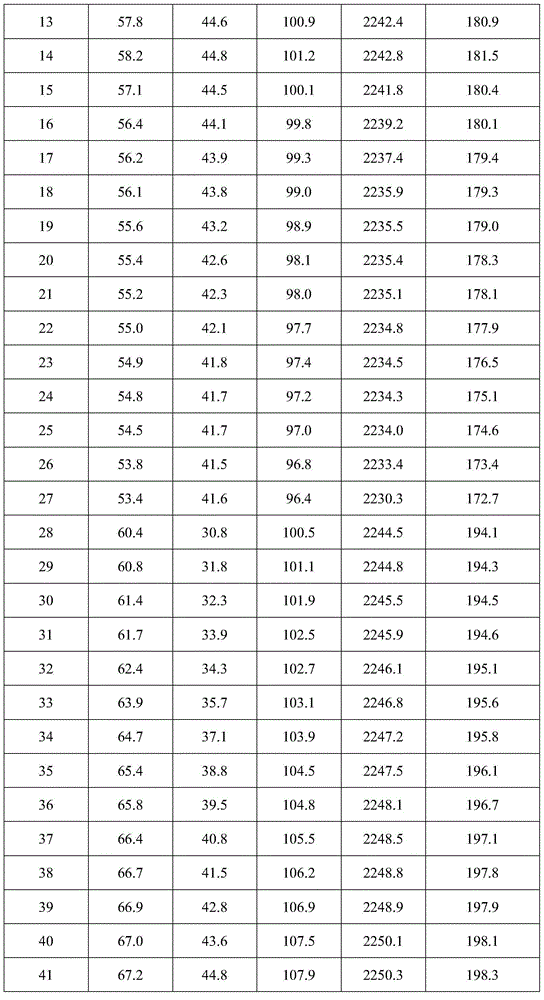

example 28

[0031] Example 28: (using polymer nucleating agent: polyvinylcyclosilane)

[0032] A polymer nucleating agent modified polyethylene terephthalate, comprising the following raw materials in parts by weight: PET: 50kg, polymer nucleating agent (polyvinylcyclosilane): 0.1kg; crystallization Accelerator (polyethylene glycol): 0.1kg; antioxidant DLTP: 0.1kg; ultraviolet absorber UV-P: 0.1kg.

[0033] According to the polymer nucleating agent described above to improve polyethylene terephthalate, the preparation method comprises the following steps: (1) respectively mixing polyvinylcyclosilane, polyethylene glycol, and PET at 80-150° C. Dry in the oven for 4-6 hours before use;

[0034] (2) Mix polyvinylcyclosilane and PET evenly, then add polyethylene glycol, antioxidant DLTP and ultraviolet absorber UV-P in sequence, mix in a high-speed mixer for 2 to 8 minutes, and use a twin-screw extruder to process Melt blending extrusion granulation. The temperature setting of the extruder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com