Beta-PPR tube and preparation method thereof

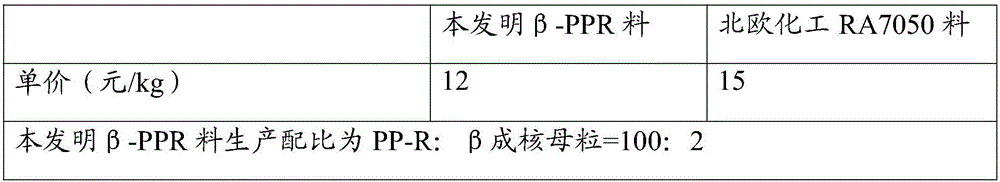

A PP-R and pipe technology, which is applied in the field of β-PPR pipe and its preparation, can solve the problems of difficulty in general popularization, high price, complicated synthesis process, etc., and achieves the advantages of general popularization and use, reduction of raw material costs, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

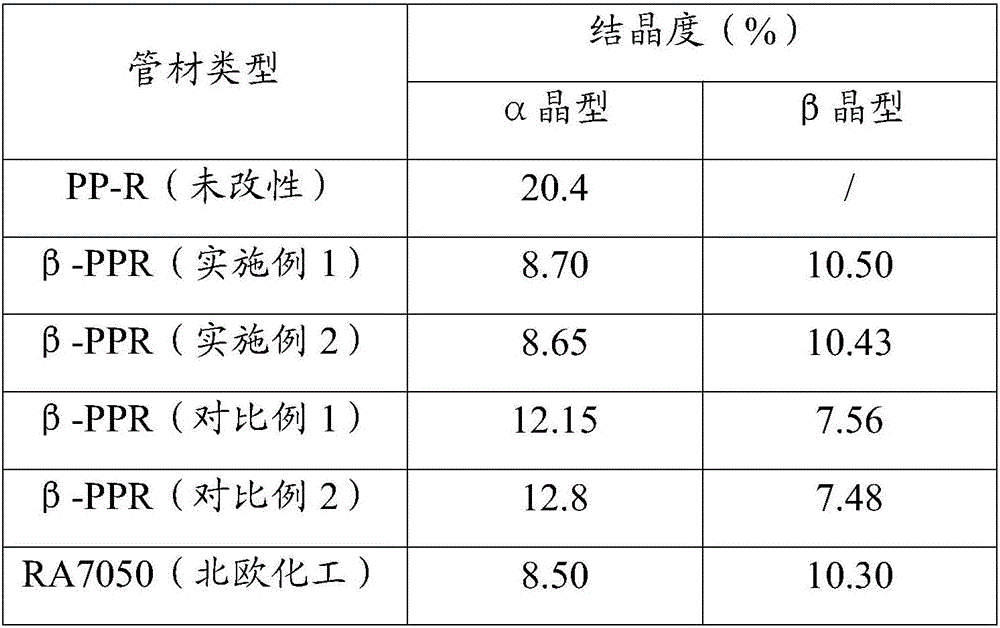

Embodiment 1

[0041] A preparation method of a β-PPR pipe in this embodiment comprises the following steps:

[0042] (1) β nucleating agent surface treatment

[0043] Mix the coupling agent (KH-550) and the β-nucleating agent in a ratio of 1:100 parts by mass, and mix them evenly through a high-speed mixer, the speed of the mixer is 500-1000rpm, and the mixing time is 10-20min;

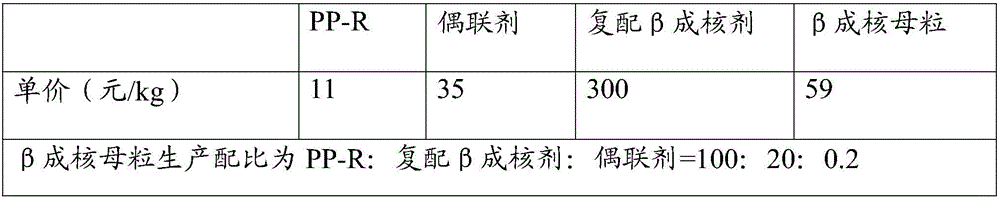

[0044] (2) Preparation of β-nucleating masterbatch

[0045] Mix the random copolymerized polypropylene resin (PP-R) with the β-nucleating agent obtained in step (1) according to the mass fraction of 100:20, fully stir with a high-speed mixer for 5-10min, and put it into the twin-screw extruder to extrude Granulation, barrel section temperature range: 170-200°C, mold section temperature range: 200-230°C, to obtain β-nucleation masterbatch;

[0046] The β-nucleating agent is TMB4 and WBG in a weight ratio of 1:0.2

[0047] (3) Preparation of β-PPR pipe

[0048] Mix random copolymerized polypropylene resin (PP-R),...

Embodiment 2

[0051] A preparation method of a β-PPR pipe in this embodiment comprises the following steps:

[0052] (1) β nucleating agent surface treatment

[0053] Mix the coupling agent (KR-TTS) and the β-nucleating agent in a ratio of 1:50 parts by mass, and mix them evenly through a high-speed mixer, the speed of the mixer is 500-1000rpm, and the mixing time is 10-20min;

[0054] (2) Preparation of β-nucleating masterbatch

[0055] Mix the random copolymer polypropylene resin (PP-R) with the β-nucleating agent after the surface treatment in step (1) according to the mass ratio of 100:20, fully stir with a high-speed mixer for 5-10min, and put it into the twin-screw extruder Extrusion granulation, the temperature range of the barrel section: 170-200°C, the temperature range of the mold section: 200-230°C, and the die temperature is 220-230°C to obtain β-nucleation masterbatch;

[0056] The β-nucleating agent is TMB5 and WBG in a weight ratio of 1:0.5.

[0057] (3) Preparation of β-PPR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com