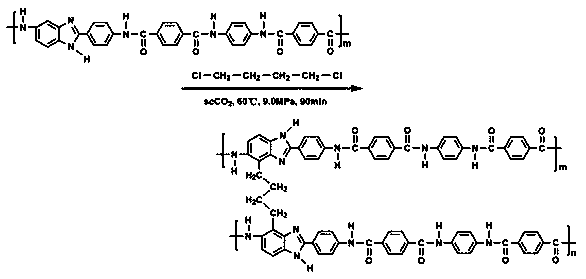

Method modifying aramid fibers in supercritical carbon dioxide environment to increase mechanical performance and surface performance

A carbon dioxide, modified aramid fiber technology, applied in fiber processing, fiber types, textiles and papermaking, etc., can solve the problems of low lateral strength of aramid fiber skin-core structure, achieve improved mechanical properties, larger grain size, Crystallized perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

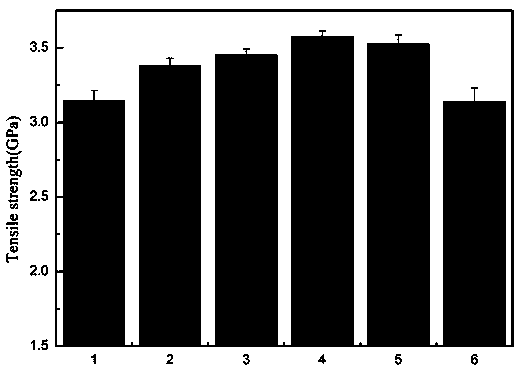

Examples

Embodiment 1

[0024] The present embodiment provides a method for modifying aramid fibers in a supercritical carbon dioxide environment to improve mechanical properties and surface properties, the method comprising the following steps:

[0025] (1) Surface cleaning of F12 fiber: put the F12 fiber to be cleaned in a Soxhlet extractor for extraction and cleaning, the cleaning solution is acetone, the cleaning temperature is 75°C, and the cleaning time is 24h; then in a constant temperature blast drying oven at 40°C Dry at constant temperature for 4h.

[0026] (2) Put the washed F12 fiber and the reaction reagent 1,4-dichlorobutane into the reactor, the mass ratio of the two is 1:70, do not touch each other, and keep the F12 fiber at 12N tension.

[0027] (3) Close the reaction kettle, cool it down to 13.9°C in an ice-water bath, pass in carbon dioxide to exhaust the air in the kettle, and continue to inflate until the pressure remains constant.

[0028] (4) Heating in an oil bath, raising th...

Embodiment 2

[0032]The present embodiment provides a method for modifying aramid fibers in a supercritical carbon dioxide environment to improve mechanical properties and surface properties, the method comprising the following steps:

[0033] (1) Surface cleaning of F12 fiber: put the F12 fiber to be cleaned in a Soxhlet extractor for extraction and cleaning, the cleaning solution is acetone, the cleaning temperature is 75°C, and the cleaning time is 24h; then in a constant temperature blast drying oven at 40°C Dry at constant temperature for 4h.

[0034] (2) Put the washed F12 fiber and the reaction reagent 1,4-dichlorobutane into the reactor, the mass ratio of the two is 1:60, and they are not in contact with each other, and the F12 fiber is kept at 6N tension.

[0035] (3) Close the reaction kettle, cool down to 13.0°C in an ice-water bath, pass in carbon dioxide to exhaust the air in the kettle, and continue to inflate until the pressure remains constant.

[0036] (4) Heating in an oi...

Embodiment 3

[0040] The present embodiment provides a method for modifying aramid fibers in a supercritical carbon dioxide environment to improve mechanical properties and surface properties, the method comprising the following steps:

[0041] (1) Surface cleaning of Kevlar 49 fibers: put the Kevlar 49 fibers to be cleaned in a Soxhlet extractor for extraction and cleaning, the cleaning solution is acetone, the cleaning temperature is 75°C, and the cleaning time is 24 hours; Dry at 40°C for 4 hours.

[0042] (2) Put the washed Kevlar 49 fiber and the reaction reagent 1,2-dichloroethane into the reaction kettle, the mass ratio of the two is 1:60, and they are not in contact with each other.

[0043] (3) Close the reaction kettle, cool down to 15.0°C in an ice-water bath, pass in carbon dioxide to exhaust the air in the kettle, and continue to inflate until the pressure remains constant.

[0044] (4) Heating in an oil bath, increasing the temperature and pressure to 80.0°C and 12.0Mpa, main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com