Process for preparing polymer ultra-fine particles by applying supercritical fluid

A technology of supercritical fluid and ultrafine particles, applied in the production of bulk chemicals, etc., to achieve the effect of perfect crystallization, pure polymer particles, and stable crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

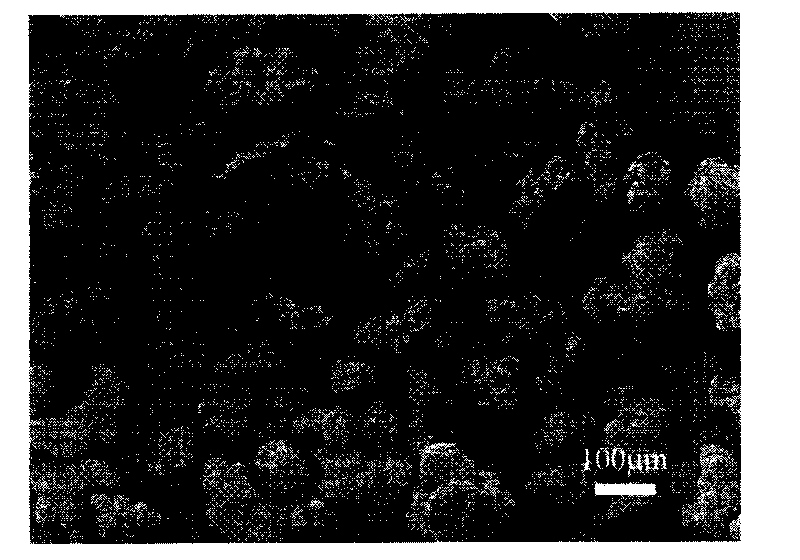

[0054] Embodiment 1, supercritical carbon dioxide prepares ultra-high molecular weight polyethylene ultrafine particles

[0055] (1) 1g of ultra-high molecular weight (weight-average relative molecular mass is 3.8×10 6 g / mol, relative molecular mass distribution is 6.8) polyethylene joins in the 50ml reactor, utilizes pump to join carbon dioxide gas in the reactor, and make the pressure in the reactor after adding carbon dioxide gas stabilize at 10MPa;

[0056] (2) Heating the reactor of step (1) to 300°C, maintaining the temperature of 300°C and the pressure of 10MPa for 2 hours, then cooling the reactor to 100°C and maintaining it for 1 hour;

[0057] (3) Release the pressure after the reaction kettle of step (2) is cooled to room temperature in a water bath at room temperature, and at the same time use the sample bottle equipped with ethanol as a collection device to collect the CO emitted from the outlet of the reaction kettle. 2 For the carried substances, the remaining ...

Embodiment 2

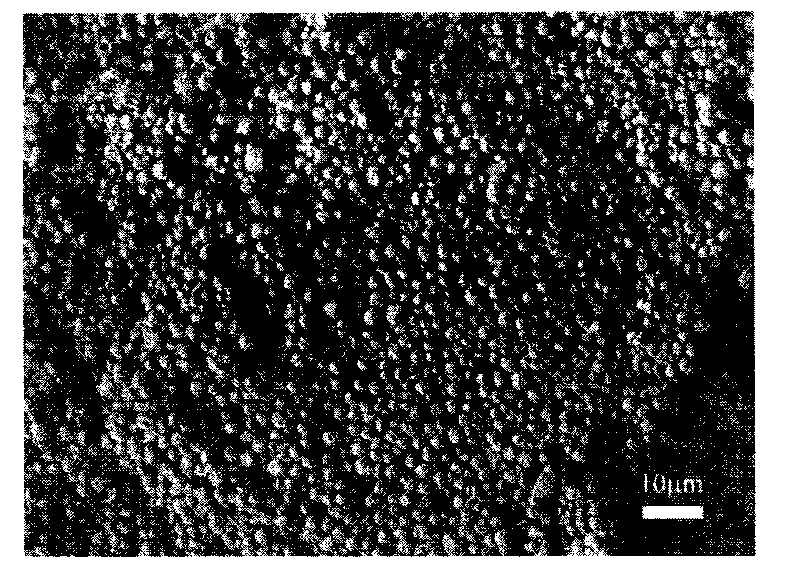

[0059] Embodiment 2, supercritical carbon dioxide prepares ultra-high molecular weight polyethylene ultrafine particles

[0060] (1) 10g ultra-high molecular weight (weight-average relative molecular mass is 3.8×10 6g / mol, relative molecular mass distribution is 6.8) polyethylene joins in 1 liter reactor, utilizes pump to join carbon dioxide gas in reactor, and make the pressure in the reactor after adding carbon dioxide gas stabilize at 20MPa;

[0061] (2) Heating the reaction kettle of step (1) to 250°C, maintaining the temperature of 250°C and the pressure of 20MPa for 2 hours, then naturally cooling to 121°C for 50 minutes at a constant temperature;

[0062] (3) Naturally cool the reactor in step (2) to 90°C for 30 minutes, then cool the reactor to room temperature in the air and release the pressure, and at the same time use the sample bottle containing ethanol as a collection device to collect the outlet of the reactor Ejected CO 2 For the carried substances, the remai...

Embodiment 3

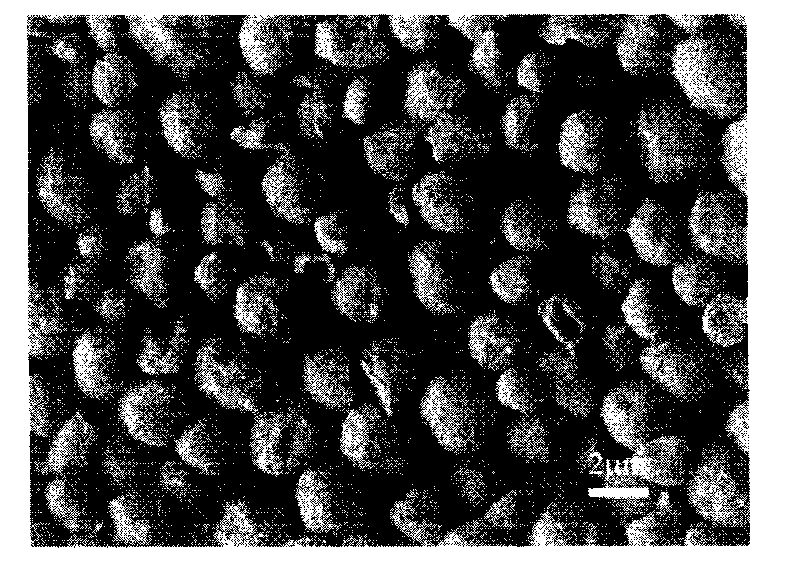

[0064] Embodiment 3, supercritical ethanol prepares ultra-high molecular weight polyethylene ultrafine particles

[0065] (1) 0.1g ultra-high molecular weight (weight-average relative molecular mass is 3.8×10 6 g / mol, relative molecular mass distribution is 6.8) polyethylene joins in the 10ml reactor, and fills up ethanol in the reactor;

[0066] (2) Heating the reactor of step (1) to 300° C., making the pressure produced by the ethanol in the reactor be 45 MPa, maintaining the temperature of 300° C. and the pressure of 45 MPa for 2 hours, then naturally cooling to 130° C. for 4 hours at a constant temperature;

[0067] (3) After the reaction kettle in step (2) is cooled to room temperature in a water bath at room temperature, directly use a device equipped with ethanol to collect the material in the reaction kettle, and take out the remaining polyethylene that has not produced polyethylene ultrafine particles for reuse ; Then vacuum-dry the obtained polyethylene ultrafine pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com