Thermotropic liquid crystal polyarylater monofilament heat treatment device and heat treatment method

A technology of heat treatment device and heat treatment method, which is applied in the direction of heat treatment of rayon filaments, textile and papermaking, and complete sets of equipment for producing man-made threads, etc. Stability and other issues, to achieve the effect of low processing cost, perfect crystallization, improved strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

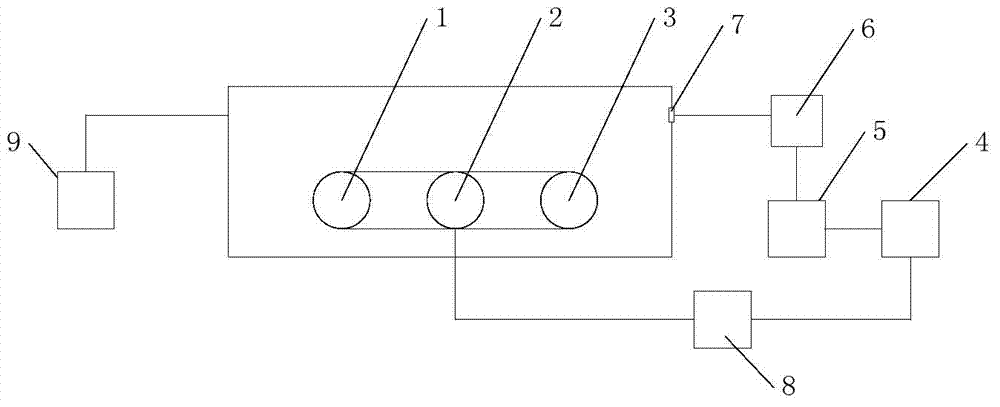

Image

Examples

Embodiment 1

[0031] The strength of the thermotropic liquid crystal polyarylate monofilament is 12.1cN / detx. The heat treatment process is that the temperature of the box and the tension roller is 270°C, the circulating wind speed is 0.5m / s, the vacuum degree is 76mm Hg, and the unwinding roller The speed is 0.01m / min, the winding roller speed is 0.02m / min, the tension roller tension is 0.1MPa, and the heat treatment time is 18h. After heat treatment, the strength of the thermotropic liquid crystal polyarylate fiber increases to 16.8cN / detx, the elongation at break is 2.4%, the strength unevenness is 0.9%, and the elongation unevenness is 1.2%.

Embodiment 2

[0033] The strength of the thermotropic liquid crystal polyarylate monofilament is 12.1cN / detx, the heat treatment process is that the temperature of the box body and the tension roller is 280°C, the circulating wind speed is 0.3m / s, the vacuum degree is 76mm Hg, and the unwinding roller The speed is 0.01m / min, the winding roller speed is 0.05m / min, the tension roller tension is 0.1MPa, and the heat treatment time is 20h. After heat treatment, the strength of the thermotropic liquid crystal polyarylate fiber increases to 18.1cN / detx, the elongation at break is 1.8%, the strength unevenness is 0.9%, and the elongation unevenness is 1.1%.

Embodiment 3

[0035] The strength of the thermotropic liquid crystal polyarylate monofilament is 13.9cN / detx. The heat treatment process is that the temperature of the box and the tension roller is 280°C, the circulating wind speed is 0.8m / s, the vacuum degree is 76mm Hg, and the unwinding roller The speed is 0.1m / min, the winding roller speed is 0.2m / min, the tension roller tension is 0.4MPa, and the heat treatment time is 28h. After heat treatment, the strength of the thermotropic liquid crystal polyarylate fiber increases to 20.6cN / detx, the elongation at break is 3.1%, the strength unevenness is 0.8%, and the elongation unevenness is 0.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com