Thermal contraction and antistatic composite master batch, preparation and use thereof

An antistatic and thermal shrinkage technology, which is applied in the field of composite masterbatch and its preparation, can solve the problems of reduced film dimensional stability, low film mechanical properties, low thermal shrinkage rate of cigarette film, etc., and achieves reduced gloss and transparency. , Long-lasting antistatic effect, perfect crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment: the preparation of composite masterbatch

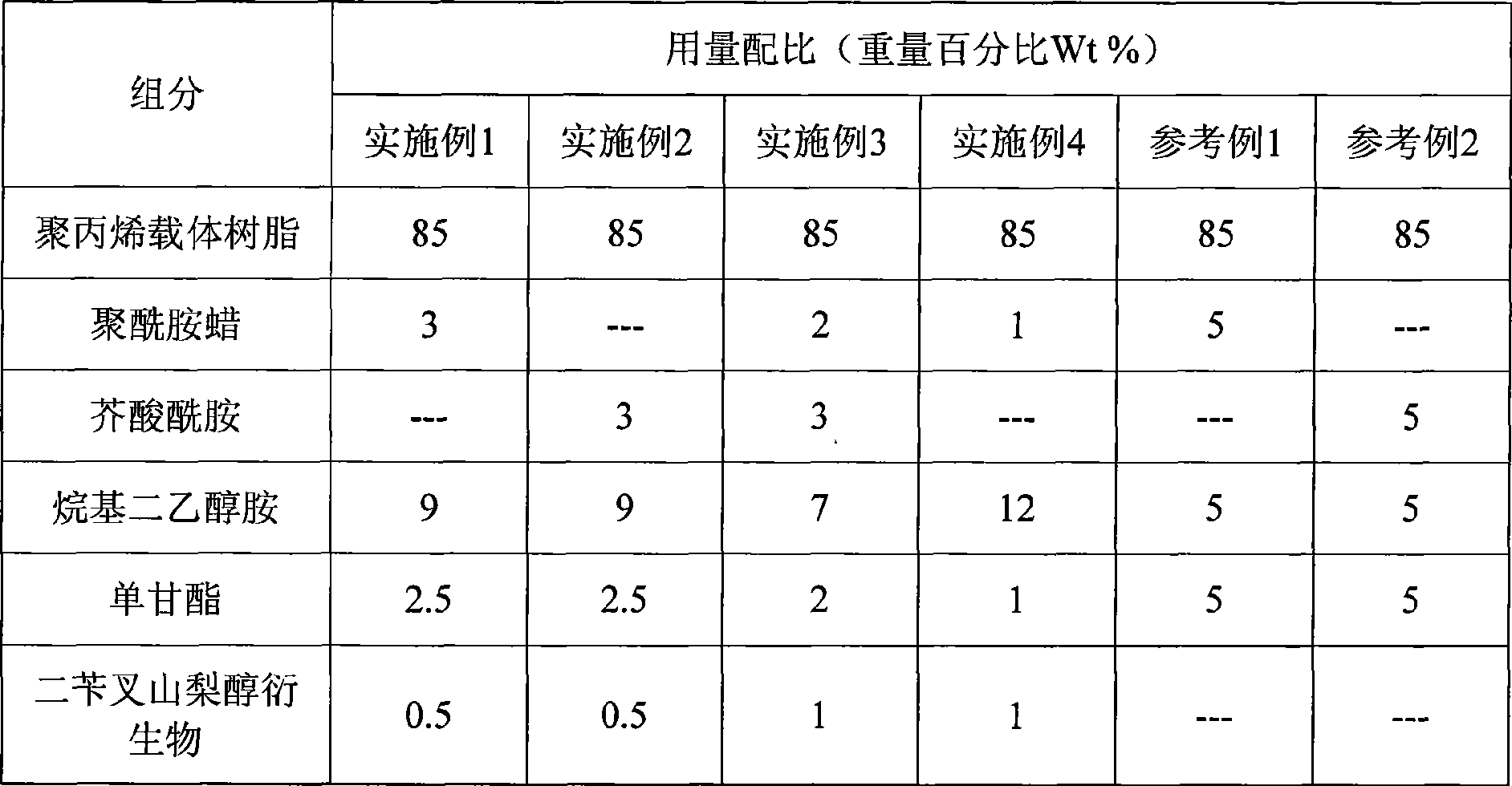

[0030] Prepare the polypropylene carrier resin and various additives according to the formula design in Table 1.

[0031] Table 1 Composite masterbatch formula

[0032]

[0033] Composite masterbatches were prepared according to the ratio in Table 1. Among them, the polypropylene carrier resin is added to the twin-screw extruder through the granular material metering and feeding equipment; the powder additive is weighed according to the designed formula and mixed evenly in the mixer, and then added to the twin-screw extruder through the powder material metering and feeding equipment. In the screw extruder; the gel additive is melted and the liquid additive is fed into the twin-screw extruder through liquid metering and feeding equipment.

[0034] The rotational speed of the twin-screw extruder is set at 200-500 rpm, and the temperature is set between 180°C and 200°C.

[0035] The polypropylene carrier resin an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com