Production and calcination process and equipment of spontaneous-combustion environmental-protection zinc oxide

A production process, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of high labor intensity, time-consuming, high production cost, etc., to reduce labor intensity and improve production Environmental and energy-saving effects are obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

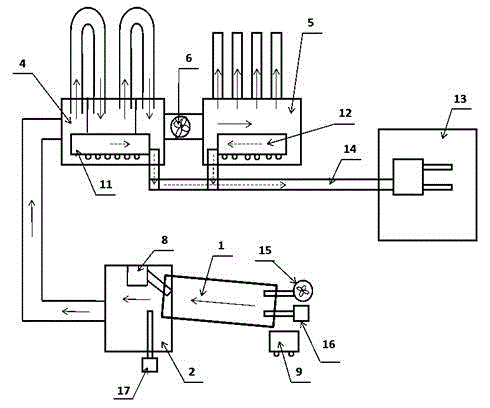

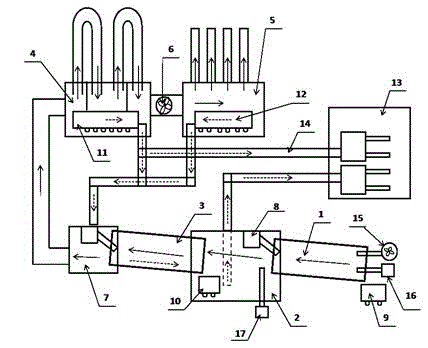

[0031] In conjunction with the accompanying drawings, the following examples of the present invention are given, but the present invention is not limited to the following examples.

[0032] The production and calcination process of zinc oxide described in this embodiment is to place zinc raw materials in the oxidation furnace, heat the oxidation furnace through external heat, and close the external heat after the temperature in the oxidation furnace reaches above 900 ° C. This temperature can make the oxidation furnace The zinc raw material inside reacts with oxygen. The negative pressure continuous production method is adopted. After the zinc raw material and oxygen are fully mixed and reacted in the oxidation furnace, the zinc raw material and oxygen undergo a redox reaction to generate zinc oxide and release a large amount of heat to burn the raw material to form a gaseous raw material. Zinc oxide is obtained after cooling process and powder collecting process. In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com