Novel early strength agent for concrete and method for preparing novel early strength agent

A technology of concrete and early strength agent, applied in the field of new concrete early strength agent and its preparation, can solve the problems of unsatisfactory concrete strength, restrict the development of early strength agent, increase the cost of preparation, etc., achieve strength improvement and wide application range , Improve the effect of early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

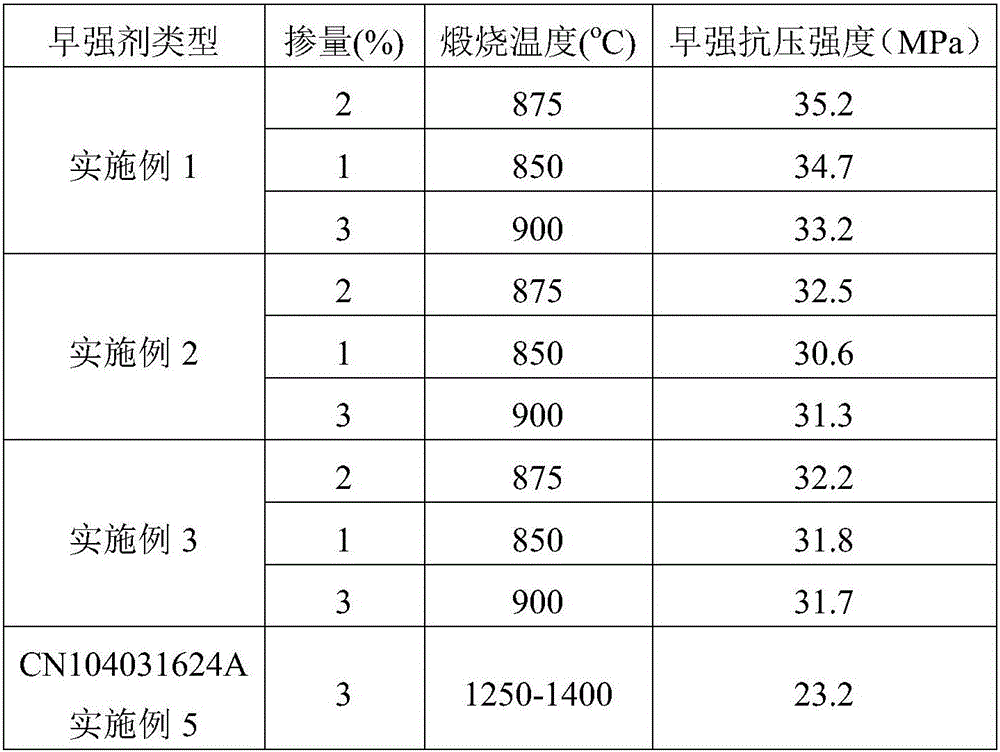

Examples

preparation example Construction

[0022] The present invention provides a novel concrete early-strength agent and its preparation method. In order to achieve the purpose, technical scheme and effect of the present invention to be clearer and clearer, the present invention will be further described in detail below.

[0023] A new type of concrete early strength agent is made of the following components in proportion by weight: 20-25 parts of CaO, 25 parts of Al 2 o 3 20~25 parts, Nb 2 o 5 4~6 parts, MgSO 4 3-7 parts, barite powder 15-20 parts, zeolite powder 15-20 parts, Bi 2 o 3 0.3~0.7 parts, Li 2 CO 3 1 to 3 parts, 0.2 to 0.4 parts of NaCl, 0.2 to 0.4 parts of KCl;

[0024] The preparation method of described novel concrete accelerator comprises the following steps:

[0025] 1) The above-mentioned components are divided into components according to the weight ratio: absolute ethanol: zirconia ball = 1:1:3, and the material is placed on a ball mill with a rotating speed of 200-300 rpm for 6-8 hour...

Embodiment 1

[0033] A new type of concrete early strength agent is made of the following components by weight: 22 parts of CaO, 22 parts of Al 2 o 3 23 parts, Nb 2 o 5 5 parts, MgSO 4 5 parts, barite powder 18 parts, zeolite powder 18 parts, Bi 2 o 3 0.5 parts, Li 2 CO 3 2 parts, 0.3 parts of NaCl, 0.3 parts of KCl.

Embodiment 2

[0035] A new type of concrete early strength agent is made of the following components in proportion by weight: 20 parts of CaO, 20 parts of Al 2 o 3 20 parts, Nb 2 o 5 4 parts, MgSO 4 3 parts, barite powder 15 parts, zeolite powder 15 parts, Bi 2 o 3 0.3 parts, Li 2 CO 3 1 part, NaCl 0.2 part, KCl 0.2 part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com