Alkaline earth metal tungstate/ molybdate red fluorescent powder and preparation method thereof

A technology of red fluorescent powder and alkaline earth metal, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of complicated follow-up process, large particle size of phosphor powder, irregular shape, etc., and achieve good crystallinity and coating performance , Uniform particles and stable reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

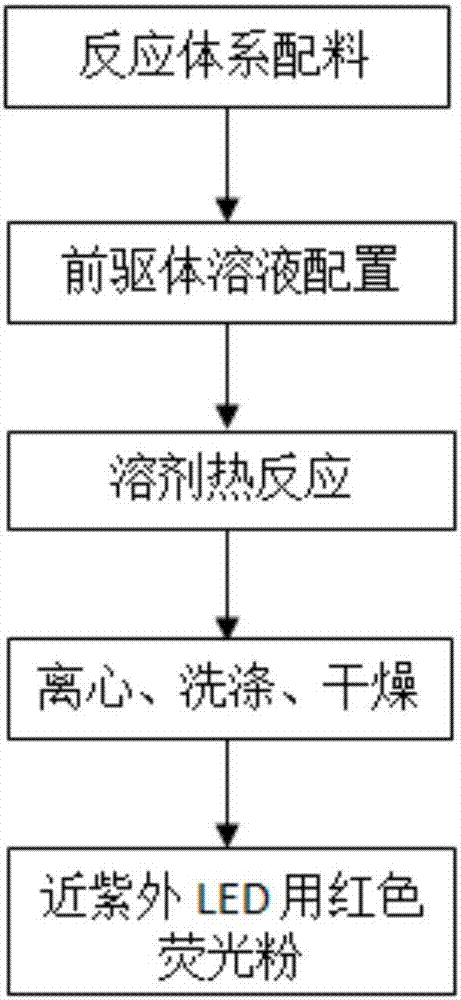

Method used

Image

Examples

Embodiment 1

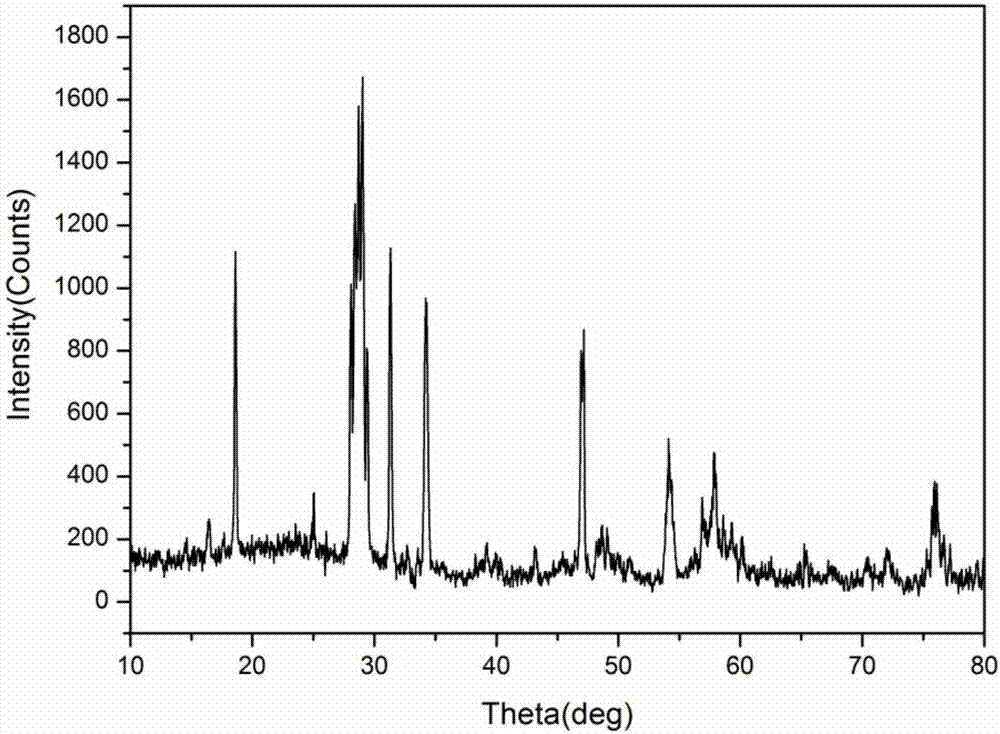

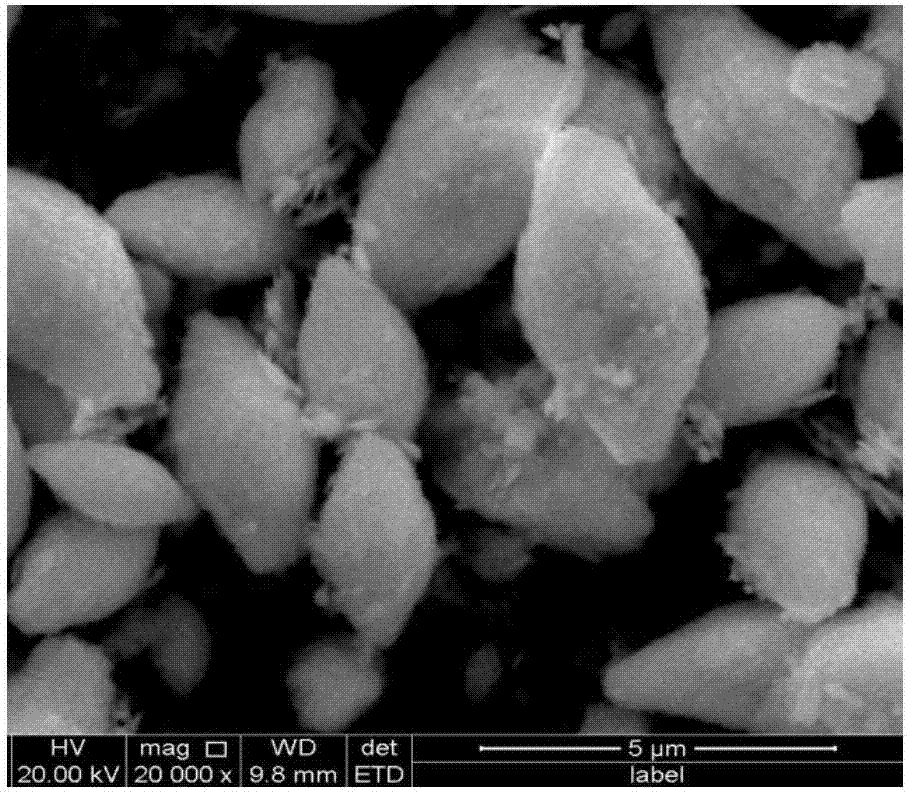

[0023] According to the molecular formula CaY 1.95 (WO 4 ) 3.5 (MoO 4 ) 0.5 :0.04Eu 3+ ,0.01Bi 3+ Weigh out CaCO 3 (A.R.) 0.1mol, Y 2 o 3 (A.R.)0.0975mol, Na 2 WO 4 (A.R.) 0.35mol, Na 2 MoO 4 (A.R.)0.05mol, Eu 2 o 3 (99.99%) 0.002mol and Bi 2 o 3(A.R.) 0.0005mol; the weighed CaCO 3 , Y 2 o 3 、Eu 2 o 3 and Bi 2 o 3 Dissolve with 1:1.2 concentrated nitric acid and heat to remove excess nitric acid, then add appropriate amount of deionized water to prepare a colorless and transparent metal cation mixed solution A; weighed Na 2 WO 4 and Na 2 MoO 4 Dissolve in an appropriate amount of deionized water to prepare anion solution B; mix solution A and solution B under continuous rapid stirring to form a precursor solution, and adjust the pH value of the precursor solution to 7 with diluted ammonia water, and then add an appropriate amount of anhydrous Ethanol makes the water-alcohol ratio in the precursor solution 2:1; move the precursor solution into the reac...

Embodiment 2

[0025] According to the molecular formula SrLa 1.9 (WO 4 ) 3 (MoO 4 ):0.08Eu 3+ ,0.02Bi 3+ Weigh out SrCO 3 (A.R.) 0.1mol, La 2 o 3 (A.R.)0.095mol, Na 2 WO 4 (A.R.) 0.3mol, Na 2 MoO 4 (A.R.) 0.1mol, Eu 2 o 3 (99.99%) 0.004mol and Bi 2 o 3 (A.R.) 0.001mol; the weighed SrCO 3 , La 2 o 3 、Eu 2 o 3 and Bi 2 o 3 Dissolve with 1:1.2 concentrated nitric acid and heat to remove excess nitric acid, then add appropriate amount of deionized water to prepare a colorless and transparent metal cation mixed solution A; weighed Na 2 WO 4 and Na 2 MoO 4 Dissolve in an appropriate amount of deionized water to prepare anion solution B; mix solution A and solution B under continuous rapid stirring to form a precursor solution, and adjust the pH value of the precursor solution to 7 with diluted ammonia water, and then add an appropriate amount of anhydrous Ethanol makes the water-alcohol ratio in the precursor solution 1:1; move the precursor solution into the reactor and ...

Embodiment 3

[0027] According to the molecular formula BaY 1.85 (WO 4 ) 2.5 (MoO 4 ) 1.5 :0.12Eu 3+ ,0.03Bi 3+ Weigh out BaCO 3 (A.R.) 0.1mol, Y 2 o 3 (A.R.)0.0925mol, Na 2 WO 4 (A.R.) 0.25mol, Na 2 MoO 4 (A.R.)0.15mol, Eu 2 o 3 (99.99%) 0.006mol and Bi 2 o 3 (A.R.) 0.0015mol; the weighed BaCO 3 , Y 2 o 3 、Eu 2 o 3 and Bi 2 o 3 Dissolve with 1:1.2 concentrated nitric acid and heat to remove excess nitric acid, then add appropriate amount of deionized water to prepare a colorless and transparent metal cation mixed solution A; weighed Na 2 WO 4 and Na 2 MoO 4 Dissolve in an appropriate amount of deionized water to prepare anion solution B; mix solution A and solution B under continuous rapid stirring to form a precursor solution, and adjust the pH value of the precursor solution to 7 with diluted ammonia water, and then add an appropriate amount of anhydrous Ethanol makes the water-alcohol ratio in the precursor solution 1:2; move the precursor solution into the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com