Heat accumulating type double-hearth lime kiln

A dual-chamber lime kiln, regenerative technology, applied in the direction of lime production, can solve the problems of uneven heating of limestone, inability to achieve high temperature calcination, and large gas resistance of stone materials, and achieves favorable heat balance, shortening residence time, and total smoke. The effect of low air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

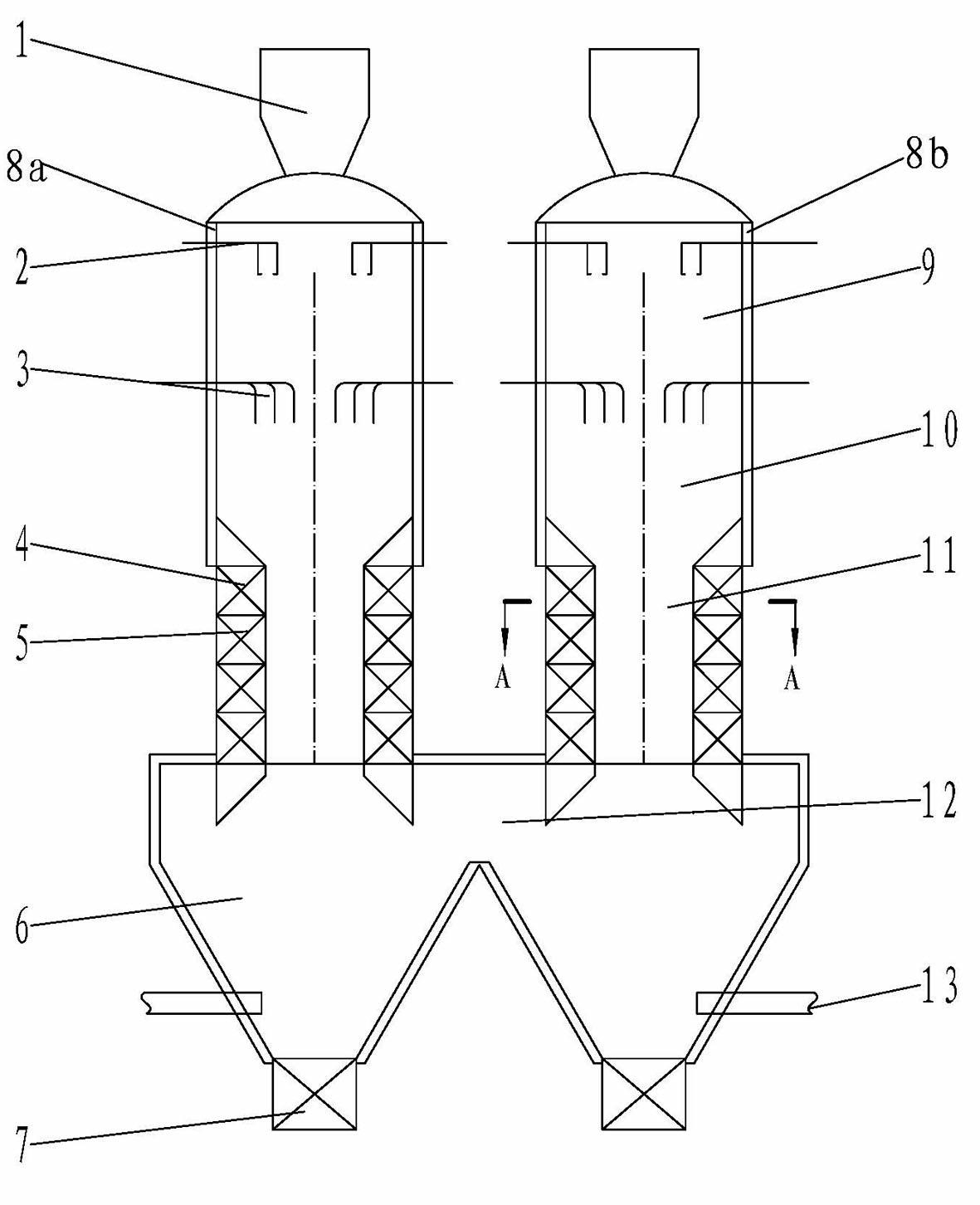

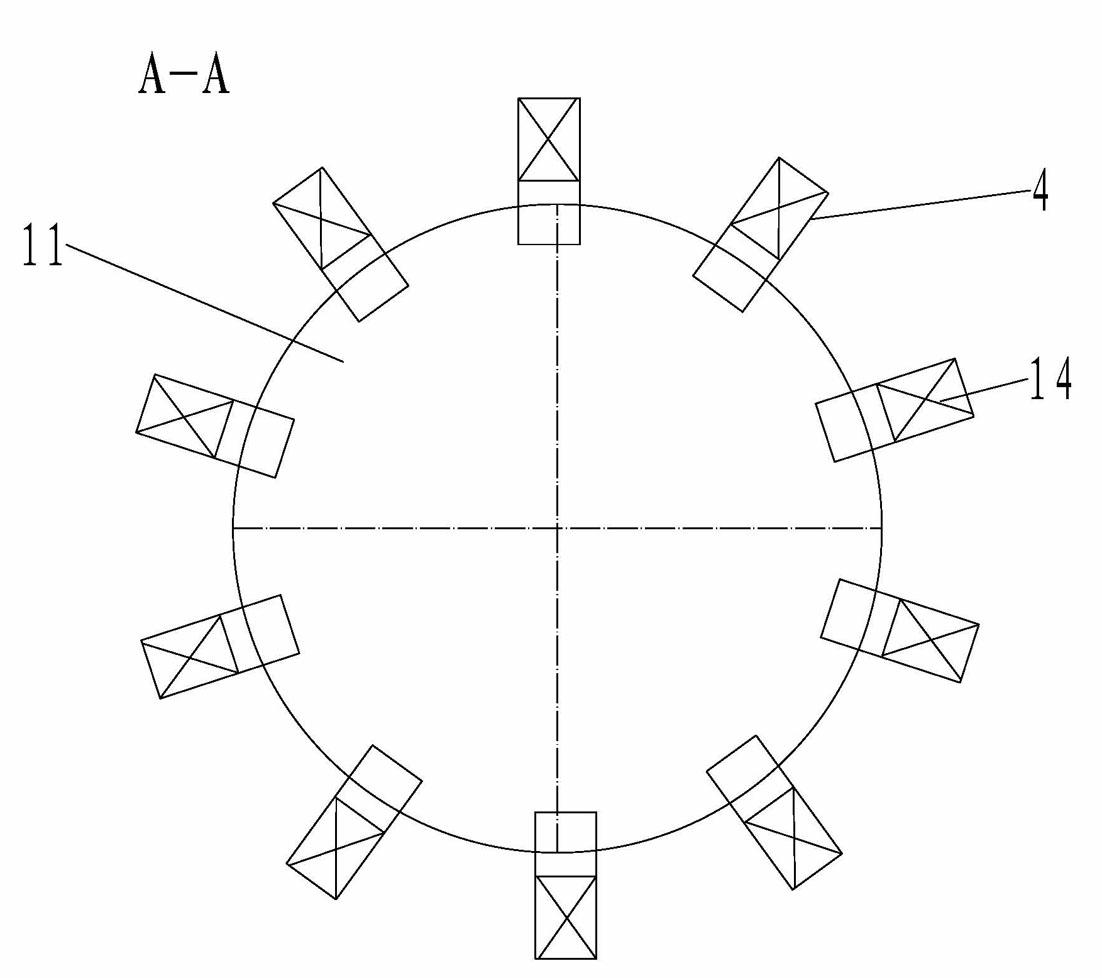

[0017] A regenerative double-chamber lime kiln of the present invention such as figure 1 As shown, it includes a feed system, a discharge system, a combustion system, an air supply system, an exhaust gas discharge system and two kiln bodies 8a and 8b arranged side by side. The cross section of the kiln body is circular. The two kiln bodies are respectively provided with a feed inlet 1, a preheating zone 9, a calcination zone 10, a high-temperature calcination zone 11, a cooling zone 6 and a discharge port 7, and the upper part of the cooling zone is provided with an annular channel 12 for communication. The two kiln bodies communicated through a ring channel. The upper part of the preheating zone is provided with a gas collecting device 2, which feeds combustion-supporting air during the calcination stage and discharges waste gas during the heat storage stage. The inlets of the gas collecting devices of the kiln body (8a, 8b) are respectively connected with the blower and the...

Embodiment 2

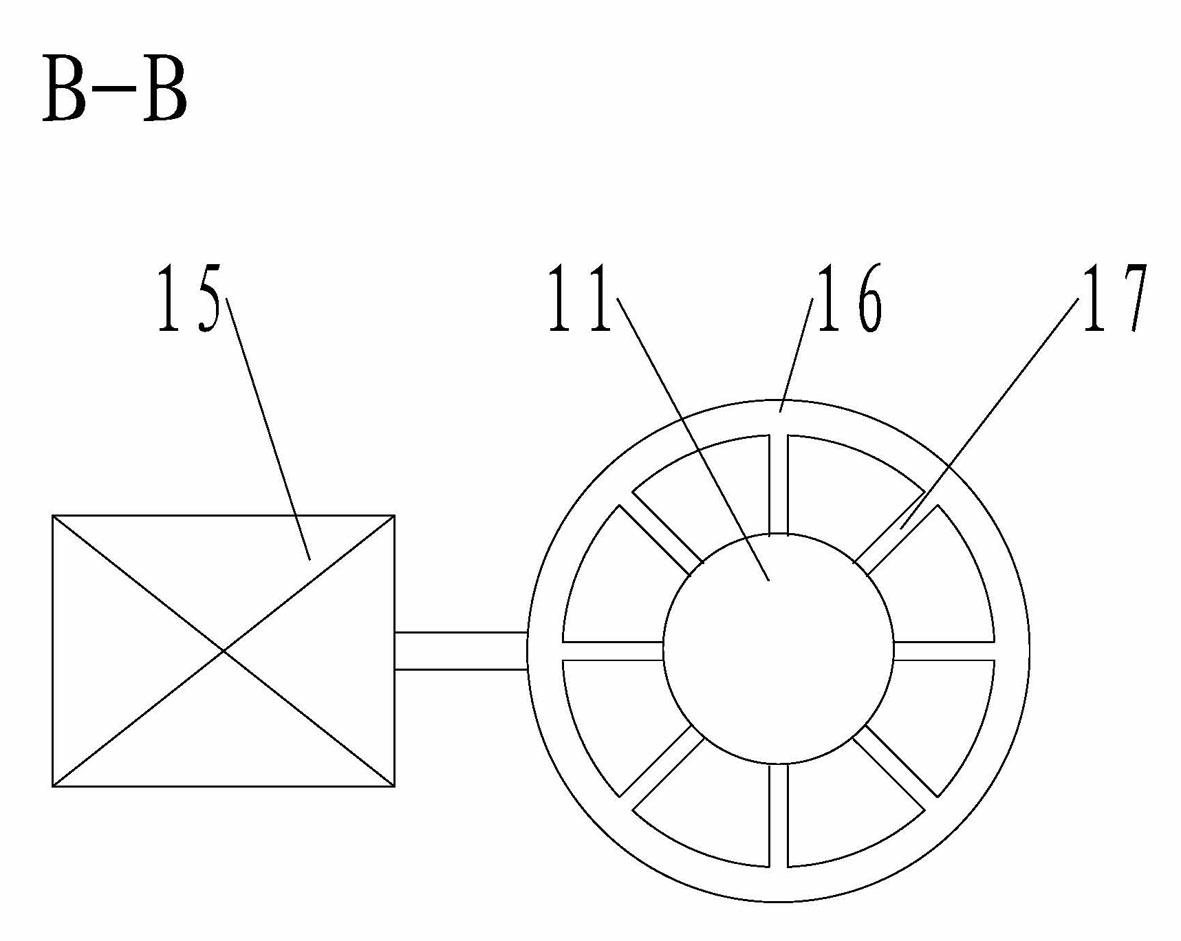

[0020] Another embodiment of the present invention is as image 3 , Figure 4As shown, the two kiln bodies are respectively provided with a feed port 1, a preheating zone 9, a calcination zone 10, a high-temperature calcination zone 11, a cooling zone 6 and a discharge port 7, and the upper part of the cooling zone is provided with an annular channel 12 for communication. The kiln bodies are connected through annular passages. The upper part of the preheating zone is equipped with a gas collecting device 2, and the inlets of the gas collecting devices of the kiln body (8a, 8b) are respectively connected with the blower and the exhaust gas discharge system, and the direction is changed through a three-way valve. The high temperature calcination zone 11 is provided with a gas heat accumulator 15, and the gas heat accumulator is connected to the high temperature preheating zone through a gas ring pipe 16 and an air inlet pipe 17. The other end of the gas heat accumulator is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com