Preparation method for early strength cement admixture containing red mud or coal gangue

A technology of coal gangue and mixed materials, applied in the field of cement materials, can solve the problems of land occupation and serious environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

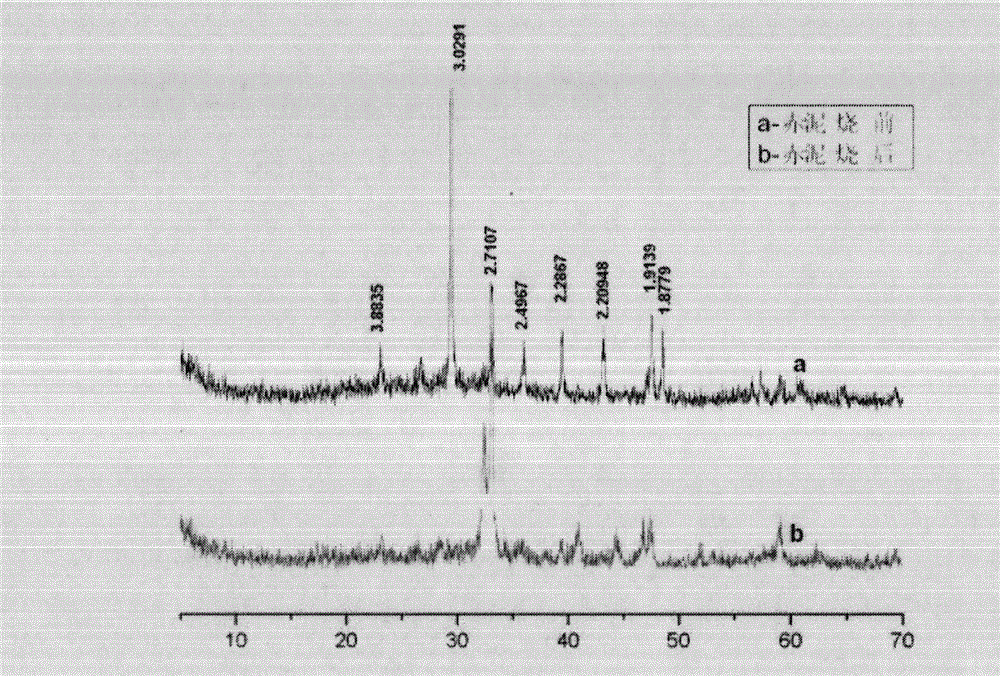

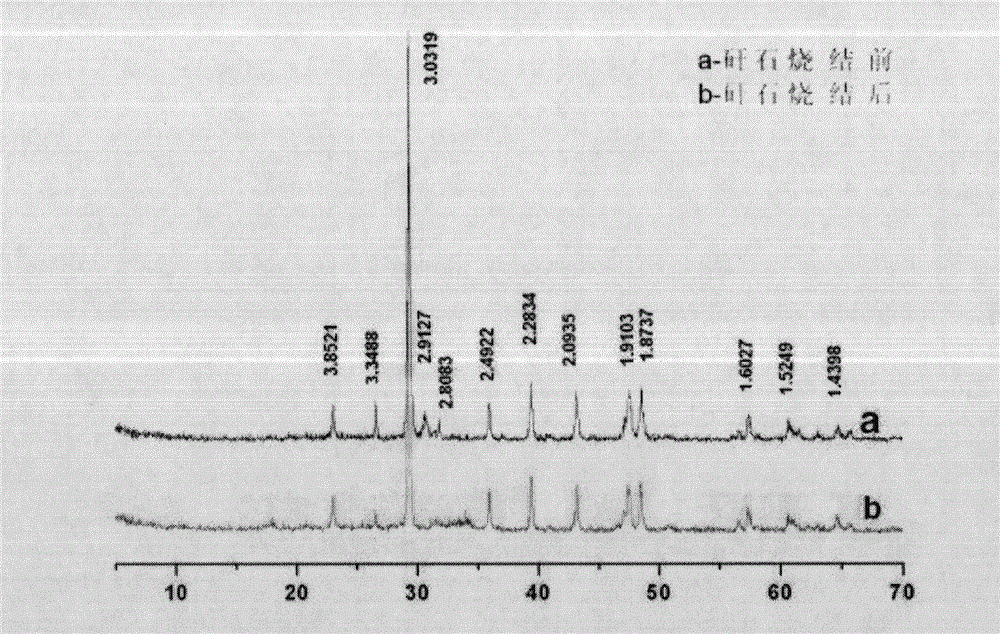

Method used

Image

Examples

example 1

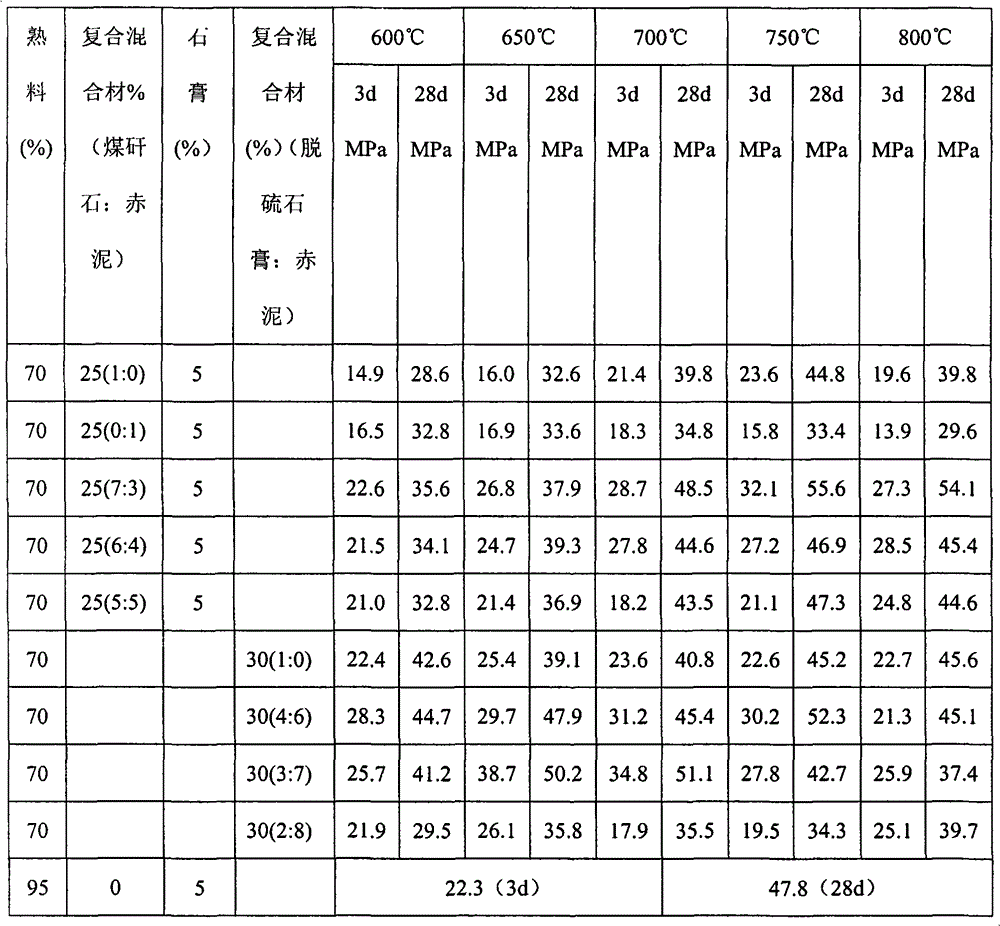

[0029] Mix the red mud and coal gangue and process the composite mixed material after treatment and calcining for 30 minutes with cement clinker and gypsum according to the ratio shown in Table 1. Add water at a gray ratio of 0.5, stir slowly for 120 seconds, stop for 15 seconds, and stop after stirring rapidly for 120 seconds. Put the clean slurry into a mold of 20×20×20mm, standard curing, and test its strength at 2d and 28d. The experimental results are shown in Table 1.

example 2

[0031] Red mud and desulfurized gypsum were processed and calcined for 30 minutes and mixed with cement clinker according to the ratio shown in Table 1. The grinding completely passed through a 0.075mm sieve, and then put into a cement slurry mixer, and water was added at a water-cement ratio of 0.5. seconds, stop for 15 seconds, stop after 120 seconds of rapid stirring, put the clean slurry into a mold of 20×20×20mm, and test its strength at 2d and 28d. The experimental results are shown in Table 1;

[0032] Table 1 The strength of the composite mixture calcined at different temperatures (the proportions in the table are all percentages by weight)

[0033]

[0034] It can be seen from Table 1 that the composite mixture obtained by mixing red mud, coal gangue or desulfurized gypsum and red mud in proportion and calcining respectively can improve the early strength of cement paste, in which red mud and coal gangue are mixed at a ratio of 3:7, red mud Mud and desulfurized gy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com