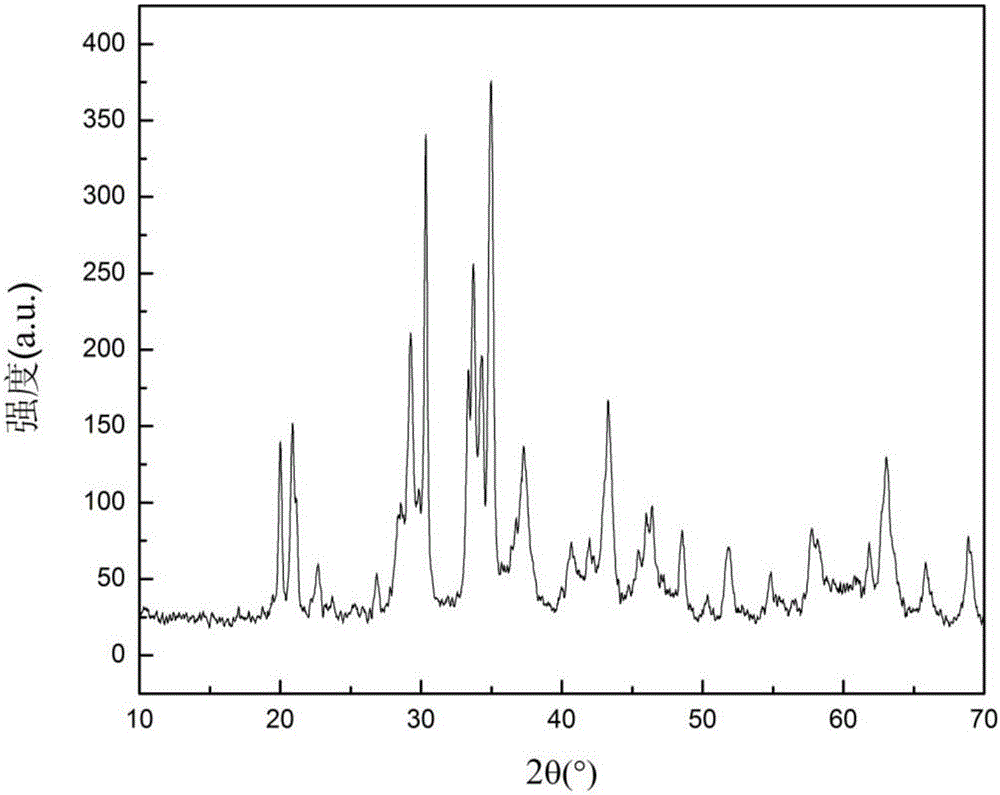

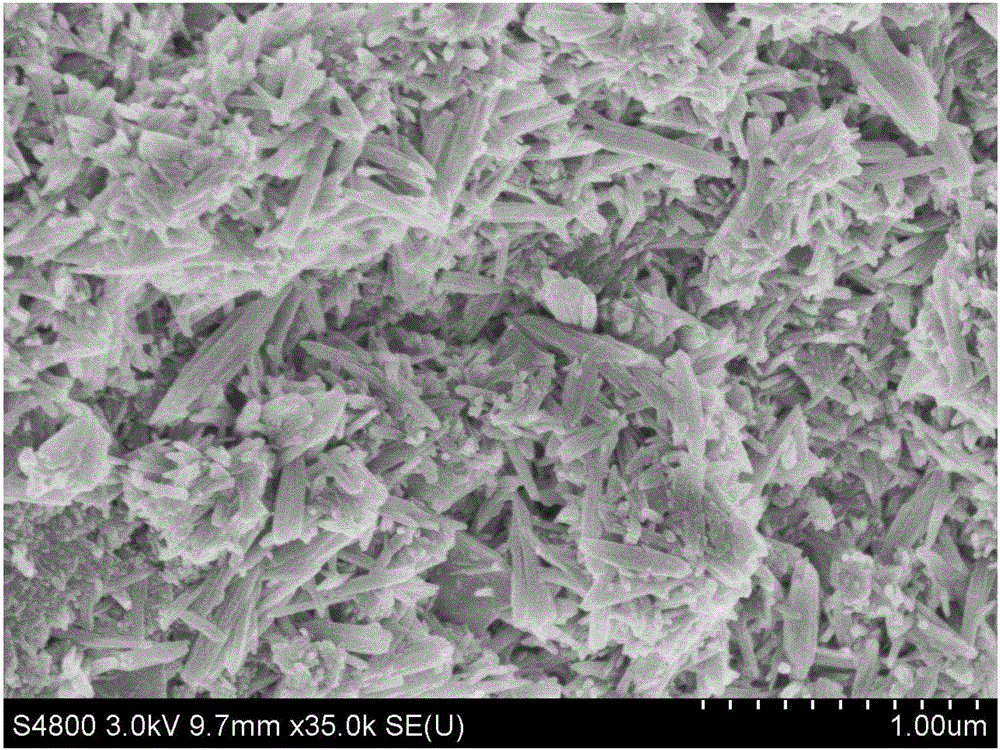

Preparation method of magnetoplumbite type CH4-CO2 reforming catalyst

A CH4-CO2, reforming catalyst technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of high energy consumption and the presence of many impurity phases , product impurity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) According to n(SrO):n(NiO):n(Al 2 o 3 )=1:1:6 molar ratio design magnetoplumbite structure oxide composition. First weigh a certain amount of sodium aluminate NaAlO 2 Chemical reagents, and use deionized water to prepare an aqueous solution with a concentration of 0.60 mol / L. Then weigh nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and strontium nitrate Sr(NO 3 ) 2 Chemical reagents, dissolved in appropriate amount of deionized water.

[0038] (2) The sodium aluminate aqueous solution was placed in a digitally controlled temperature-adjusting ultrasonic instrument, and the nickel nitrate solution was first slowly added into it under the action of continuous stirring and ultrasonic waves at 50°C, and the strontium nitrate solution was continued to be slowly added after 10 minutes. Then the prepared mass concentration of 1% HNO 3 The solution was slowly added dropwise to the beaker, the pH value was adjusted to 9.5, and the ultrasonic stirring was continued for 20 min ...

Embodiment 2

[0042] (1) According to n(SrO):n(NiO):n(Al 2 o 3 )=1:1:6 molar ratio design magnetoplumbite structure oxide composition. First weigh a certain amount of sodium aluminate NaAlO 2 Chemical reagents, and use deionized water to prepare an aqueous solution with a concentration of 0.65mol / L. Then weigh nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and strontium nitrate Sr(NO 3 ) 2 Chemical reagents, dissolved in appropriate amount of deionized water.

[0043] (2) The sodium aluminate aqueous solution was placed in a numerically controlled temperature-adjusting ultrasonic instrument, and the nickel nitrate solution was slowly added to it under the action of continuous stirring and ultrasonic waves at 45°C, and then the strontium nitrate solution was continued to be slowly added after 5 minutes. Then the prepared mass concentration of 1% HNO 3 The solution was slowly added dropwise into the beaker, the pH value was adjusted to 10, and the ultrasonic stirring was continued for 30 min to...

Embodiment 3

[0047] (1) According to n(SrO):n(NiO):n(Al 2 o 3 )=1:1:6 molar ratio design magnetoplumbite structure oxide composition. First weigh a certain amount of sodium aluminate NaAlO 2 Chemical reagents, and use deionized water to prepare an aqueous solution with a concentration of 0.50 mol / L. Then weigh nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and strontium nitrate Sr(NO 3 ) 2 Chemical reagents, dissolved in appropriate amount of deionized water.

[0048] (2) The sodium aluminate aqueous solution was placed in a digitally controlled temperature-adjusting ultrasonic instrument, and the nickel nitrate solution was first slowly added to it under the action of continuous stirring and ultrasonic waves at 45°C, and then the strontium nitrate solution was continued to be slowly added after 8 minutes. Then the prepared mass concentration of 1% HNO 3 The solution was slowly added dropwise into the beaker, the pH value was adjusted to 9.0, and the ultrasonic stirring was continued for 25 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com