Preparation machine of high-temperature structural ceramic

A technology for preparing machines and ceramics, applied in the direction of forming indenters, etc., can solve the problems of heat loss of ceramic sealing rings, reducing the degree of heating of ceramic sealing rings, and easy expansion of sealing rings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

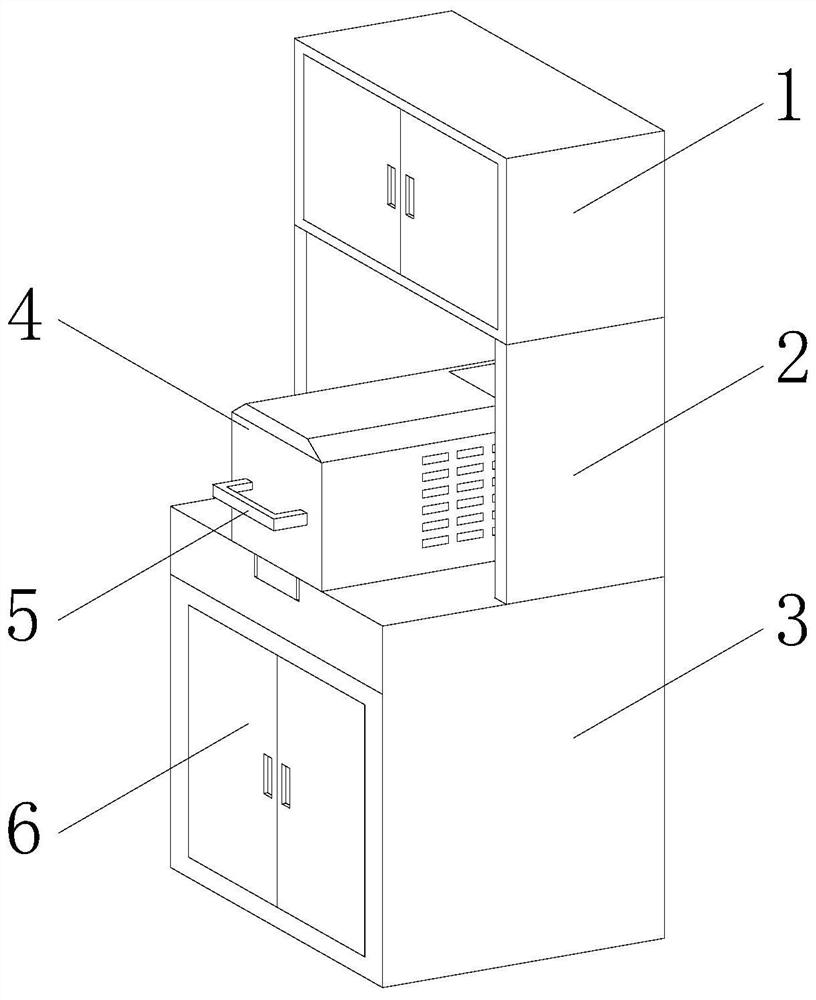

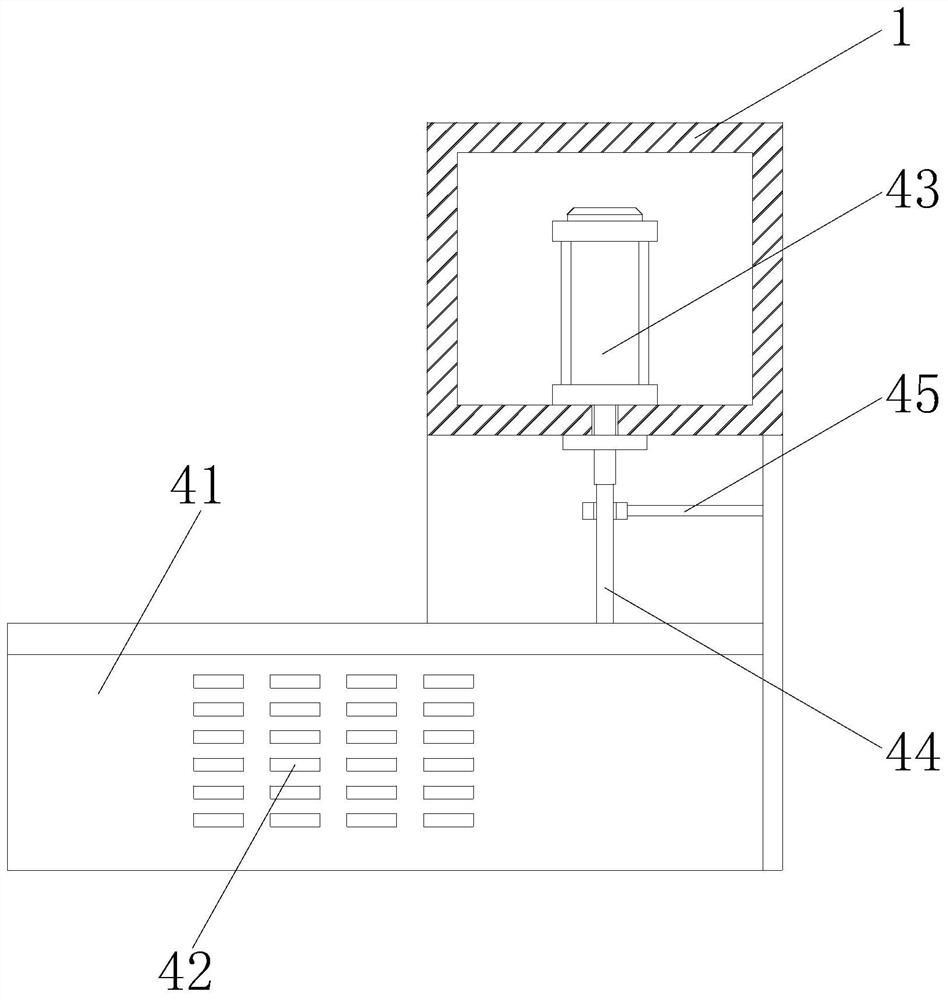

[0026] as attached figure 1 To attach Figure 6 Shown:

[0027] The present invention is a preparation machine for high-temperature structural ceramics, the structure of which includes a placement box 1, a support plate 2, a workbench 3, a preparation box 4, a handle 5, and a box door 6, and the bottom of the placement box 1 is welded to the top of the support plate 2 , the lower end of the support plate 2 is welded to the upper surface of the workbench 3, the lower end of the preparation box 4 is slidably installed inside the upper end of the workbench 3, the front end of the preparation box 4 is welded with a handle 5, and the box door 6 is hinged to the workbench 3 front surface, the preparation box 4 includes a calcined molding box 41, a heat dissipation hole 42, a cylinder 43, a connecting rod 44, and a guide ring 45, and the outer surface of the calcined molding box 41 is embedded with a heat dissipation hole 42, and the cylinder 43 is fixedly installed Inside the stor...

Embodiment 2

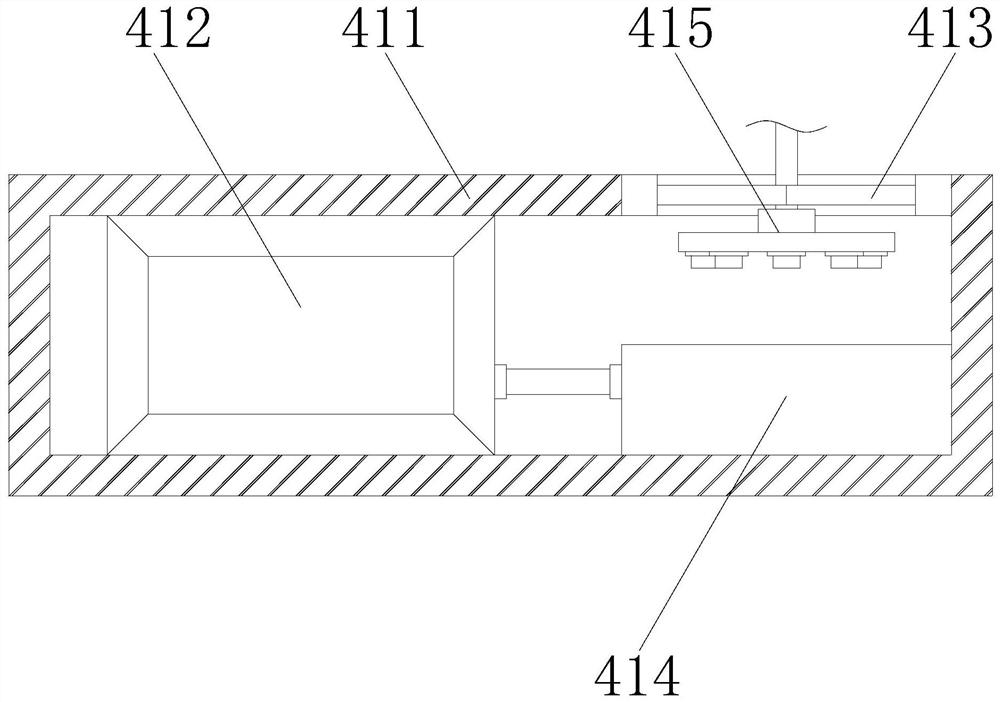

[0035] as attached Figure 7 to attach Figure 9 Shown:

[0036] Wherein, the extruding mechanism 415 includes a horizontal plate 15a, a spring 15b, and a pressing block mechanism 15c. The middle part of the upper surface of the horizontal plate 15a is fixed to the lower end of the connecting rod 44, and the inside of the horizontal plate 15a is welded to the upper end of the spring 15b. And the lower end of the spring 15b is fixed to the upper surface of the briquetting mechanism 15c, and the briquetting mechanism 15c is installed inside the lower end of the horizontal plate 15a by clearance fit. There are nine briquetting mechanisms 15c distributed with the nine molding cavities 14c match the vertical position of the briquetting mechanism 15c to ensure that the press block mechanism 15c vertically squeezes the inside of the molding cavity 14c, ensuring that the thickness of the ceramic seal ring remains vertical after molding.

[0037] Wherein, the briquetting mechanism 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com