A biomass gasification system and method

A gasification system and biomass technology, applied in the field of biomass energy preparation, can solve problems such as low production efficiency and poor quality of gas produced by equipment, and achieve the effects of convenient operation, improved gasification effect, and avoidance of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

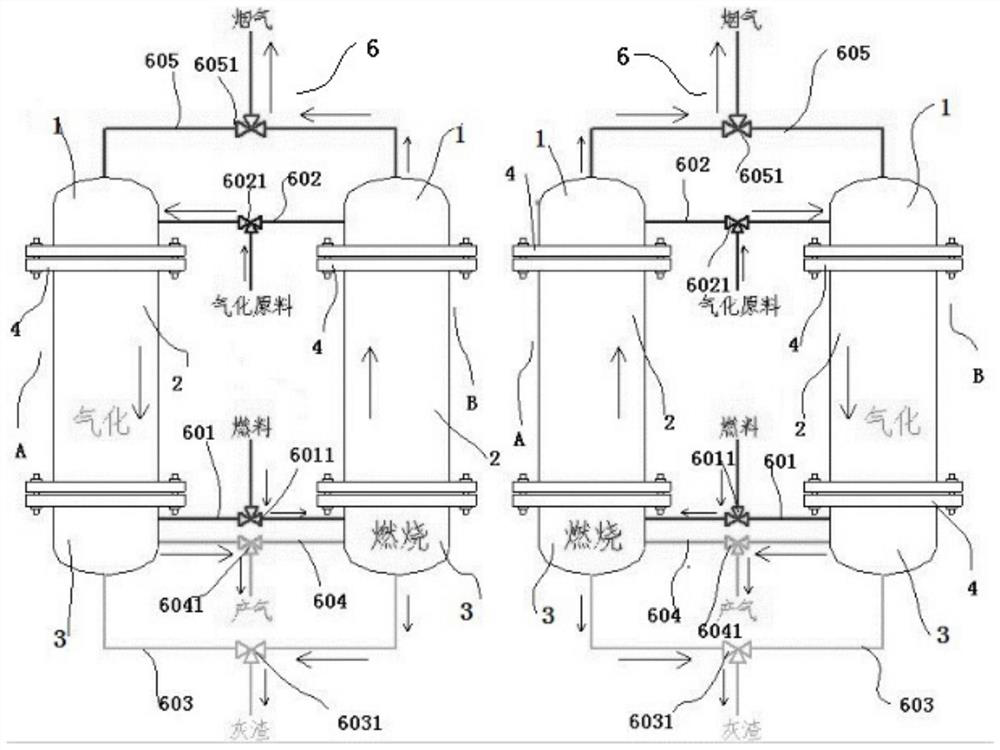

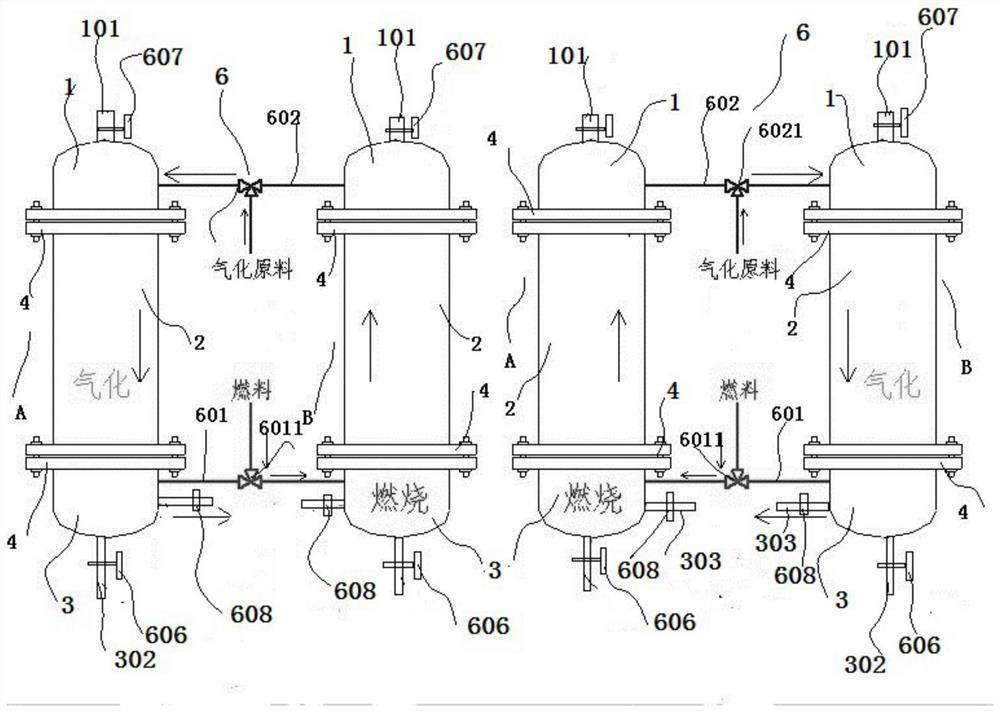

[0050] A biomass gasification system, the biomass gasification system comprising:

[0051] The first biomass gasifier A and the second biomass gasifier B connected by the gas reversing device 6;

[0052] The first biomass gasifier A and the second biomass gasifier B both include:

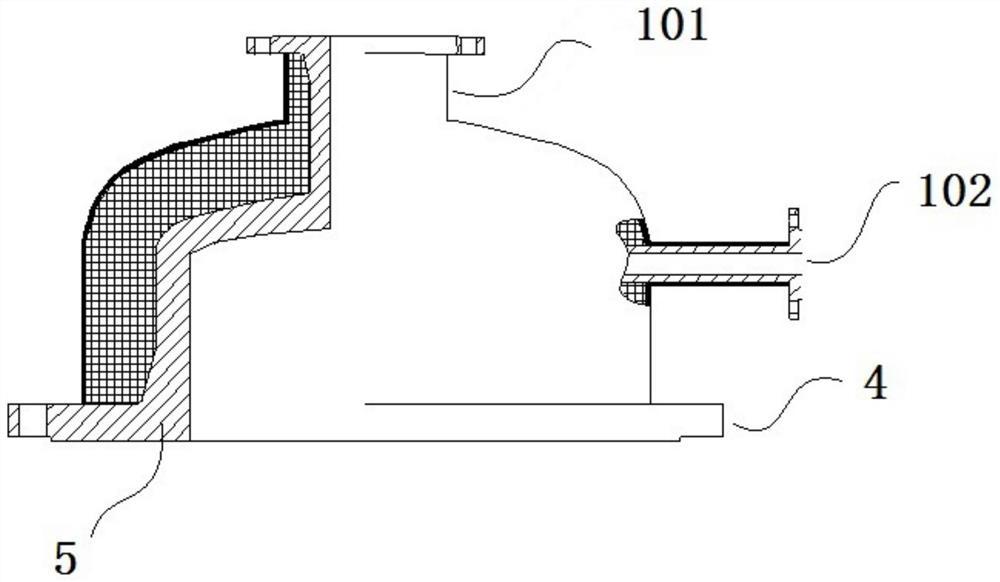

[0053] The feed chamber 1, regenerator 2 and combustion chamber 3 are manufactured separately from top to bottom, and are connected by a flange structure 4; The heat pipes 202 are airtightly arranged, and refractory cotton 203 is filled between the heat storage pipes 202, so as to ensure the heat insulation effect of the heat storage chamber 2. The biomass raw material undergoes a high-temperature gasification process in the heat storage pipes. The ash outlet 302 and the gas production outlet 303, the ash outlet 302 are arranged at the bottom of the combustion chamber 3, the flue gas outlet 101 and the gasification raw material inlet 102 are arranged in the feeding chamber 1, and the flue gas outle...

Embodiment 2

[0083] Using embodiment one figure 1 The device, under the condition of gasification temperature at 1035°C and ER value (that is, the ratio of the amount of air supplied by biomass gasification to the amount of air required for complete biomass combustion theory) is 0.2, 0.3, 0.4, 0.6, micron-sized sawdust Biomass gasification reaction is carried out separately as raw material.

[0084] Specific steps are as follows:

[0085] Step S1: First, preheat the combustion chamber to 250°C, connect the fuel delivery pipe 301, the ash discharge port 302 and the flue gas discharge port 101 of the first biomass gasifier A, Sawdust raw material at a rate of 18kg / h~30kg / h, air at a rate of 1.656m 3The rate of / h is transported to the combustion chamber 3 through the fuel delivery pipe for combustion. When the gasification temperature reaches 1035°C, the ash generated by the combustion is discharged from the ash discharge port 302, and the smoke generated is discharged from the smoke disch...

Embodiment 3

[0090] Using embodiment one figure 1 The device, under the conditions of gasification temperature of 941°C and ER value (that is, the ratio of the amount of air supplied by biomass gasification to the amount of air required for the complete combustion of biomass) of 0.2, 0.3, 0.4, and 0.6, micron-sized sawdust Biomass gasification reaction is carried out separately as raw material.

[0091] Specific steps are as follows:

[0092] Step S1: First, preheat the combustion chamber to 250°C, connect the fuel delivery pipe 301, the ash discharge port 302 and the flue gas discharge port 101 of the first biomass gasifier A, Sawdust raw material at a rate of 18kg / h~30kg / h, air at a rate of 1.656m 3 The rate of / h is transported to the combustion chamber 3 through the fuel delivery pipe for combustion and heat storage. When the gasification temperature reaches 1035°C, the ash generated by combustion is discharged from the ash discharge port 302, and the smoke generated is discharged fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com