A heavy metal sewage treatment process

A treatment process and sewage treatment technology, applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as increasing biological toxicity, endangering environmental health, increasing operational difficulty, etc., to achieve Stable chemical properties and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

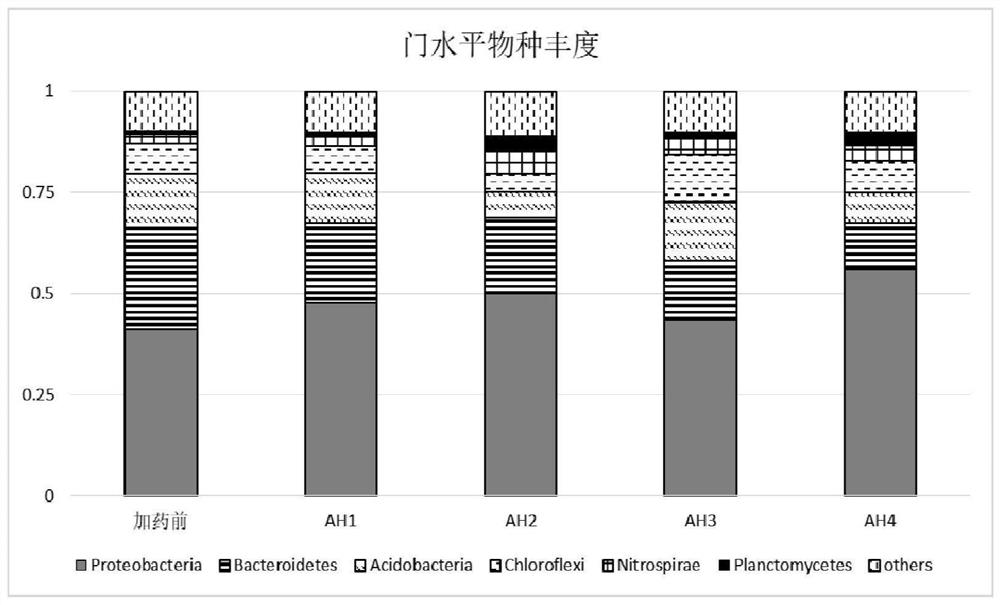

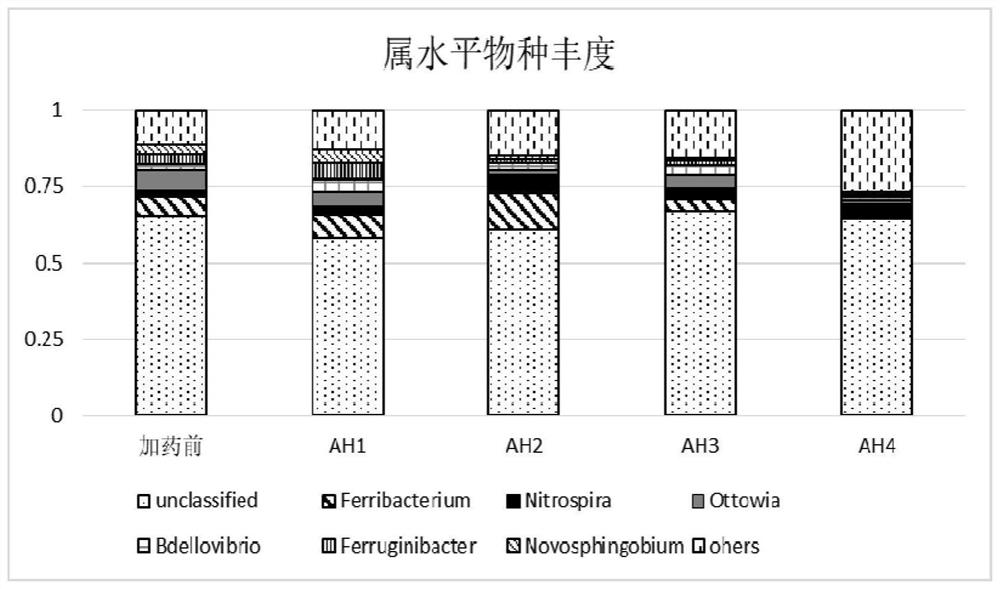

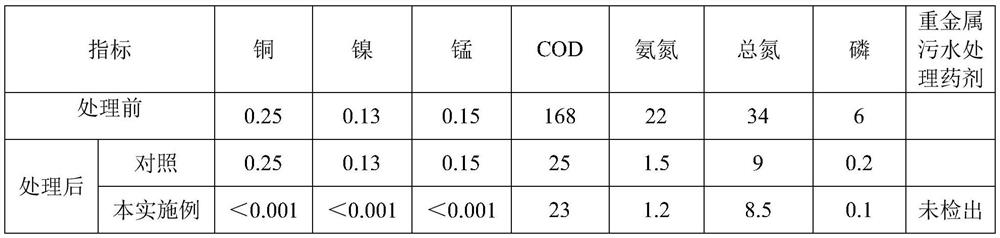

[0038] The main process of the treatment facilities of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant have a pH value of 6.8. The wastewater contains heavy metals such as copper ions, nickel ions, and manganese ions. The treatment process does not design a heavy metal removal unit. The heavy metals in the effluent exceeded the discharge standard. The present embodiment handles above-mentioned sewage, specifically as follows:

Embodiment approach

[0039]Implementation method: the sewage enters the primary reaction tank, and the water treatment coagulant is added as an iron salt coagulant. The calculation basis for the dosage is: B1 is 600mg / L, Bs is set to 300mg / L, and a is 3; the calculation shows that the sewage enters After treating the primary reaction pool, add water treatment coagulant 9mg / L (iron salt coagulant 9mg / L); stir rapidly for 3min (G value 600s -1 ), stirring slowly for 5min (G value 50s -1 );

[0040] After standing still for 2 hours, after coagulation and sedimentation, the supernatant enters the secondary reaction tank for biochemical treatment, and the heavy metal sewage treatment agent is added to the water outlet drop well at the end of the biochemical treatment. In this example, the dosage of the heavy metal water treatment agent is calculated. Basis: The sum of C1 heavy metals is 0.53mg / L, Cs is set at 0.05mg / L, and k is 30. It is calculated that adding heavy metal water treatment chemicals is ...

Embodiment 2

[0044] The main process of the treatment facilities of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant have a pH value of 7.2. The wastewater contains heavy metals such as lead ions, nickel ions, and zinc ions. The treatment process does not design a heavy metal removal unit. The heavy metals in the effluent exceeded the discharge standard. The present embodiment handles above-mentioned sewage, specifically as follows:

[0045] Implementation method: the sewage enters the primary reaction tank, and the water treatment coagulant is added as an aluminum salt coagulant. The calculation basis of the dosage is: B1 is 600mg / L, Bs is set to 300mg / L, a is 3, and the calculated sewage enters the treatment Add water treatment coagulant 9mg / L (dosing amount of aluminum salt coagulant 9mg / L) to the primary reaction tank; stir rapidly for 5min (G value 700s -1 ), stirring slowly for 7min (G value 80s -1 );

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com