Heavy metal sewage treatment agent

A sewage treatment and heavy metal technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing biological toxicity, endangering environmental health, increasing operation difficulty, etc. The effect of chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

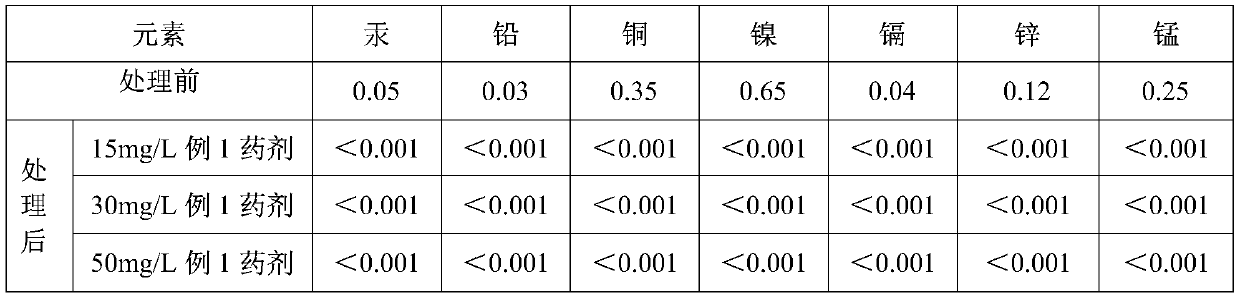

[0018] Embodiment 1 The influence of pH and heavy metal species on treatment effect

[0019] Take the following heavy metal standard solutions to prepare simulated heavy metal water samples containing mercury (II), lead (II), copper (II), nickel (II), cadmium (II), zinc (II) and manganese (II), respectively.

[0020] The heavy metal treatment agent of this example mainly comprises the following raw materials in parts by weight: 2 parts of anionic polyacrylamide; 5 parts of chitosan; 12 parts of montmorillonite; 15 parts of calcium chloride; 12 parts of sodium alginate; 30 parts of tetraacetic acid; 24 parts of sodium dimethyl dithiocarbamate.

[0021] Specific treatment method: Take 500 ml of three simulated heavy metal water samples, adjust the pH to 5.8, 6.8 and 7.8 in turn, then add 5 mg / L of heavy metal treatment agent, stir and react for 2 minutes, then directly filter with a 0.45 micron filter membrane, using inductive coupling The plasma-mass spectrometer was used to d...

Embodiment 2

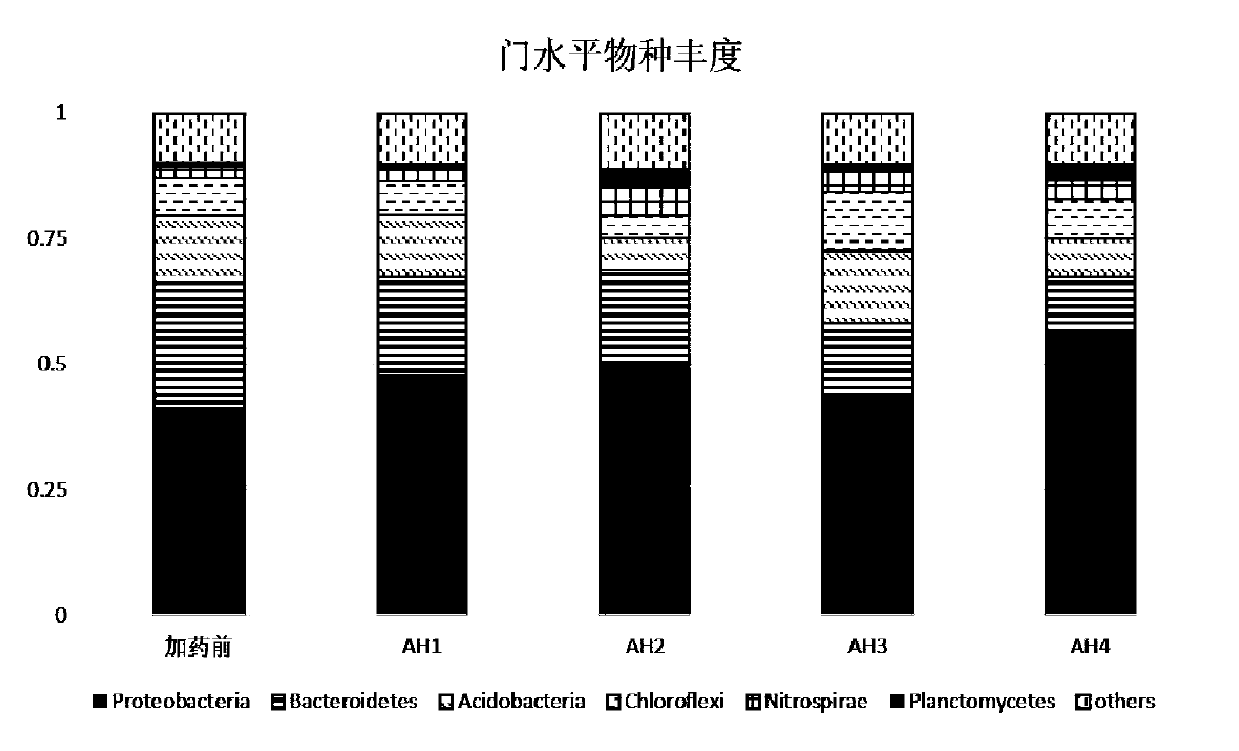

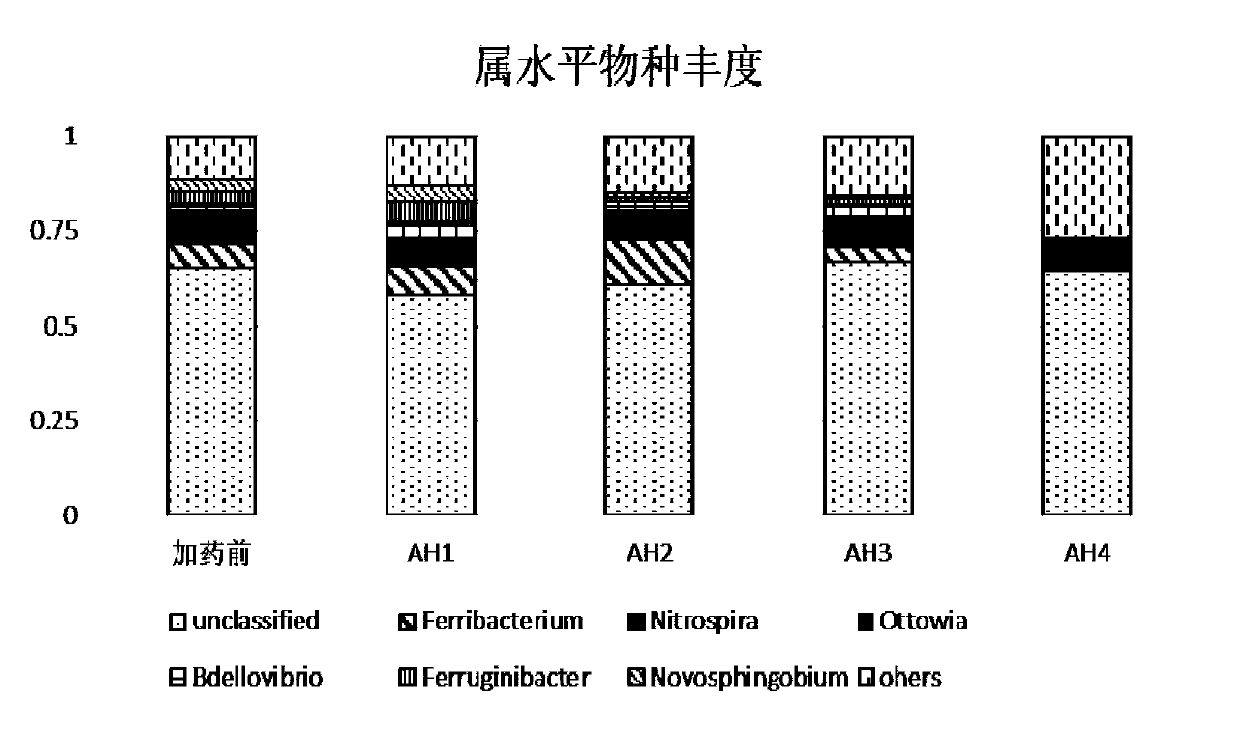

[0025] Embodiment 2 The influence of treatment agent of the present invention on biochemical treatment system

[0026] The main process of the first-phase and second-phase treatment facilities of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant have a pH value of 6.5-7.5. For heavy metals such as cadmium ions, zinc ions, and manganese ions, the treatment process did not design a heavy metal removal unit, resulting in heavy metals in the effluent exceeding the discharge standard.

[0027] Treatment process: At the end of the biochemical tank, the sludge mixture is dropped from the biochemical tank into the well to add different dosages of heavy metal sewage treatment agents (prepared according to Example 1). Under the turbulent mixing state, fully mix and contact with the wastewater for 5 minutes, and enter the secondary settling tank with the sludge mixture for mud-water separation. Take the effluent fro...

Embodiment 3

[0041] Embodiment 3 Compounding effect of heavy metal sewage treatment agent components of the present invention

[0042] Take the following heavy metal standard solutions to prepare simulated heavy metal water samples containing mercury (II), lead (II), copper (II), nickel (II), cadmium (II), zinc (II) and manganese (II), respectively. The heavy metal treatment medicament of the present invention and the medicament other than the formula ratio of the heavy metal treatment medicament of the present invention are respectively adopted.

[0043] The heavy metal treatment medicament of this example (prepared by Example 1), the medicament A other than the heavy metal treatment medicament formula ratio of the present invention, the medicament B other than the heavy metal treatment medicament formula ratio of the present invention, the composition of A and B is specifically as follows:

[0044] The heavy metal sewage treatment agent A comprises the following raw materials in parts by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com