Frequency conversion power module of all-in-one machine of explosive-proof frequency conversion motor

A technology of power module and variable frequency motor, which is applied to the output power conversion device, the conversion of AC power input to DC power output, and the direction of electric components, etc., can solve the problems of inconvenient maintenance and replacement in the well, and the water quality cannot be guaranteed to be particularly good, and achieve savings. Area and volume, easy maintenance and replacement, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

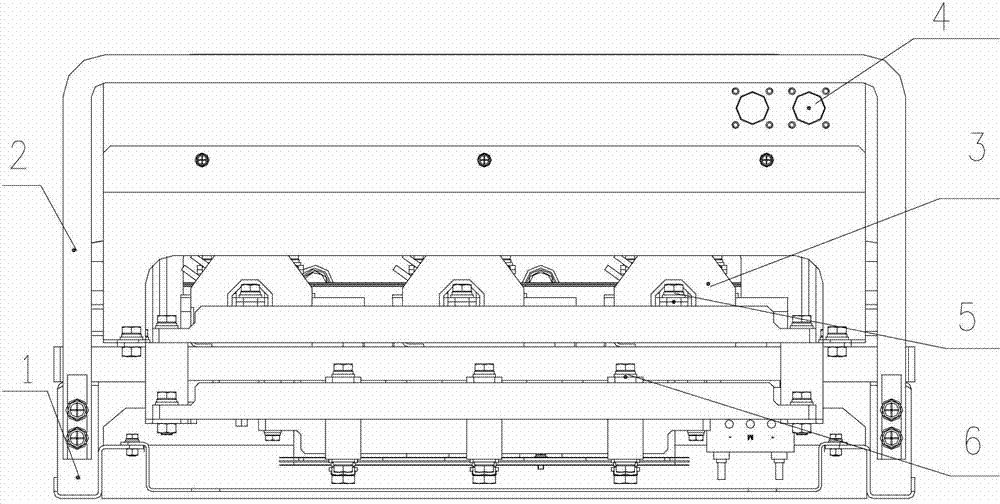

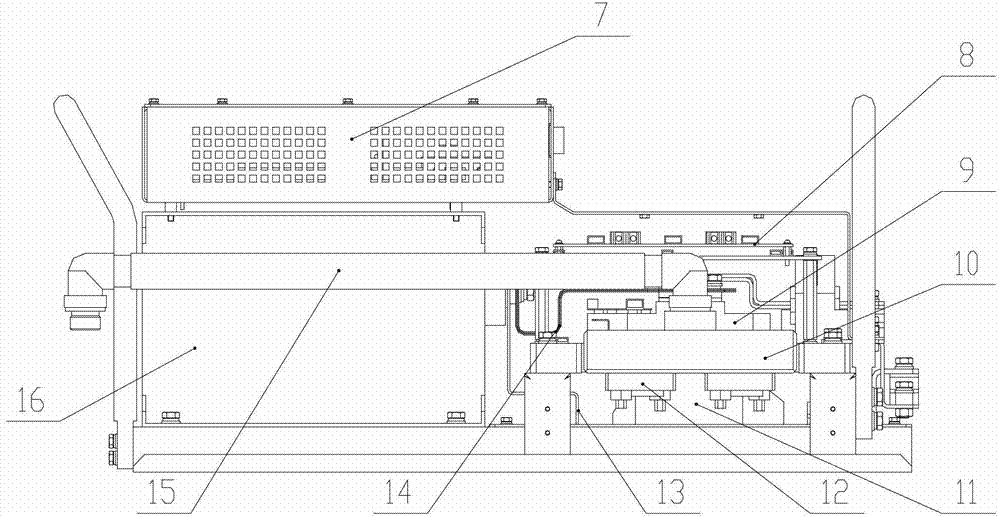

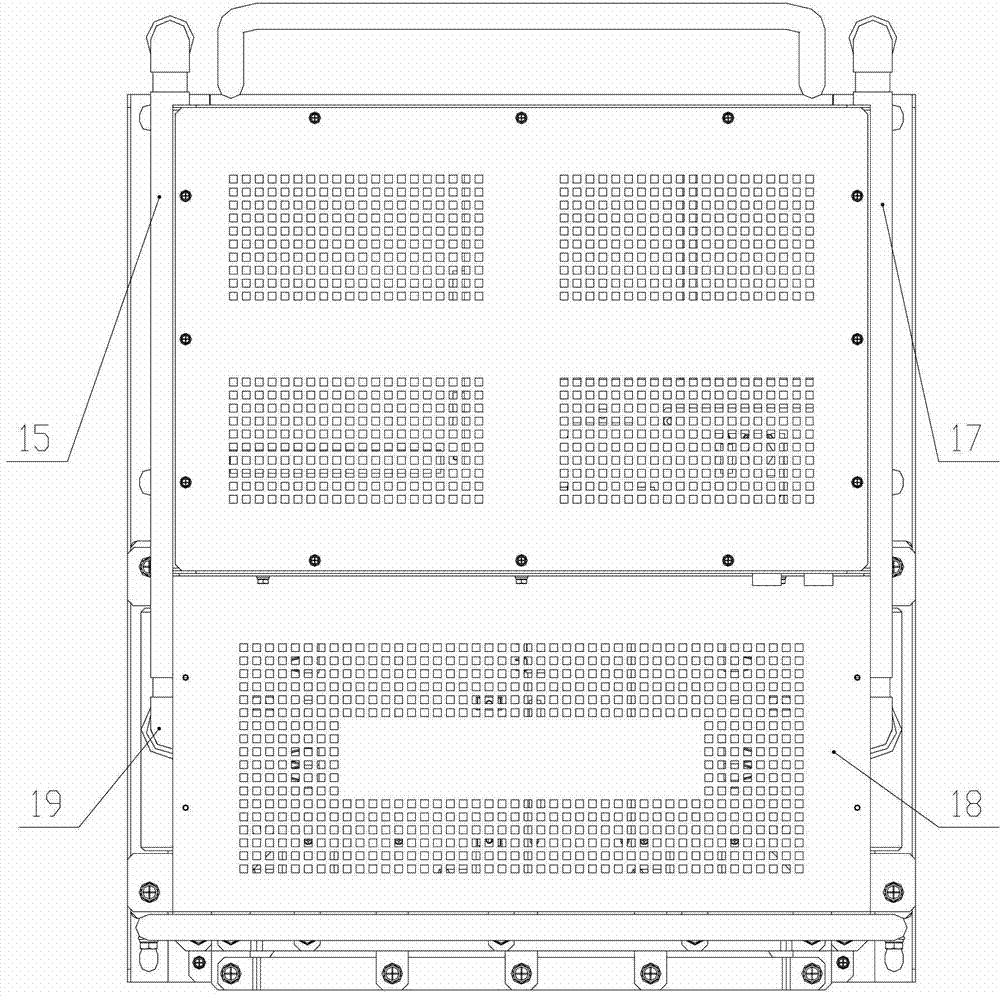

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] An embodiment of the present invention provides a frequency conversion power module of a frequency conversion motor integrated machine, including: a frame, an IGBT component, a DC capacitor, a rectifier diode, a low-inductance composite busbar, an AC laminated busbar, a drive circuit component, a control circuit component, Water-cooled radiator, discharge resistor, water inlet high-pressure hose and water outlet high-pressure hose;

[0045] The water-cooled radiator is installed on the support column on the front side of the rack; the IGBT element is installed on the upper surface of the water-cooled radiator; the rectifier diode and discharge resistor are installed on the lower surface of the water-cooled radiator;

[0046] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com