A fuel supercritical combustion test equipment

A combustion test and supercritical technology, which is applied in gas turbine engine testing, jet engine testing, etc., can solve the problems of constant compression ratio and short test time, and achieve the effects of improving safety, convenient and quick operation, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

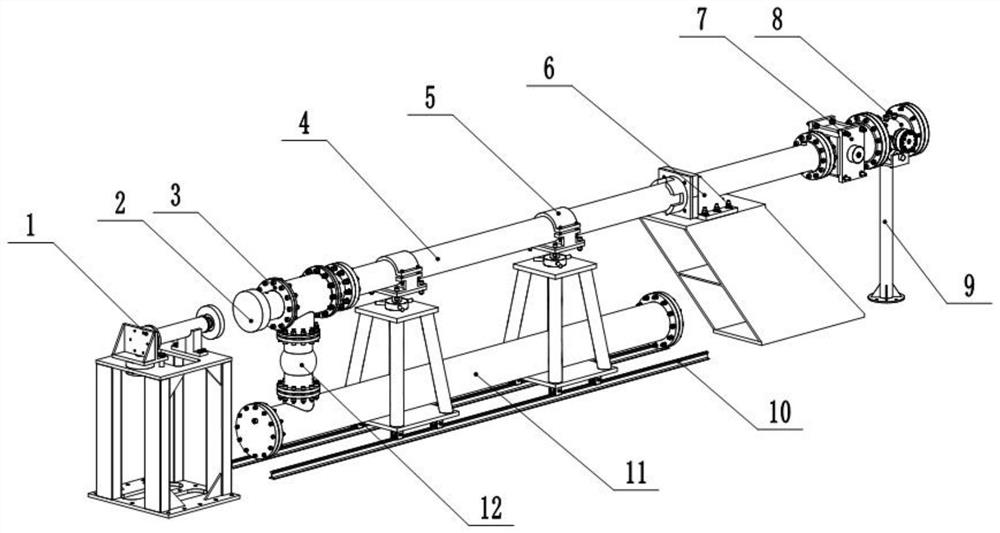

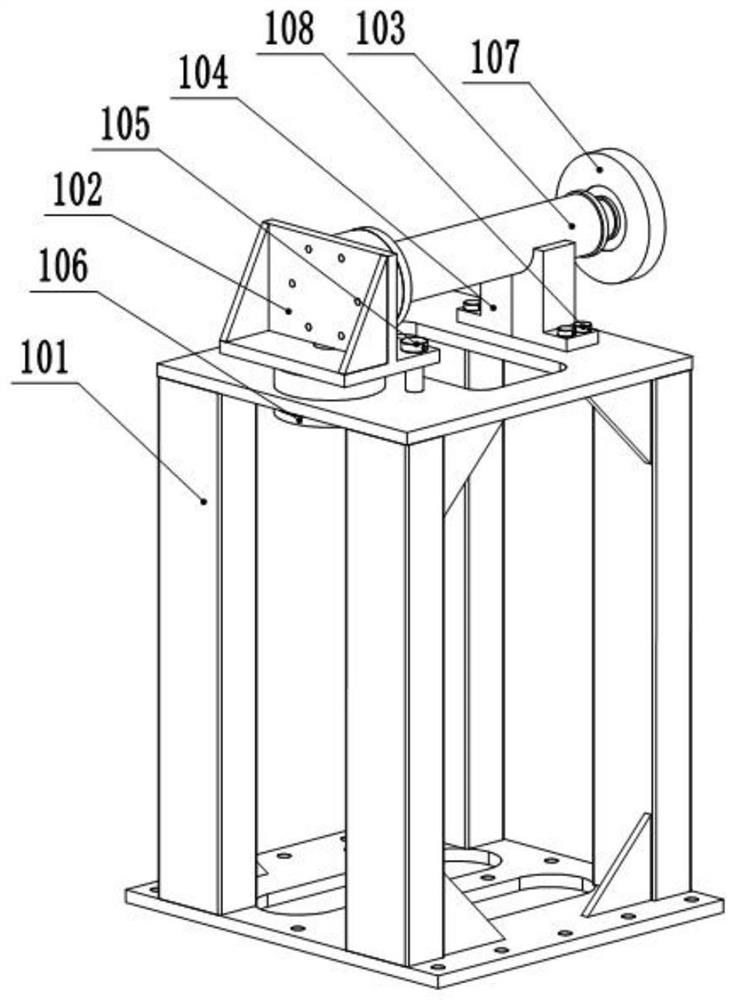

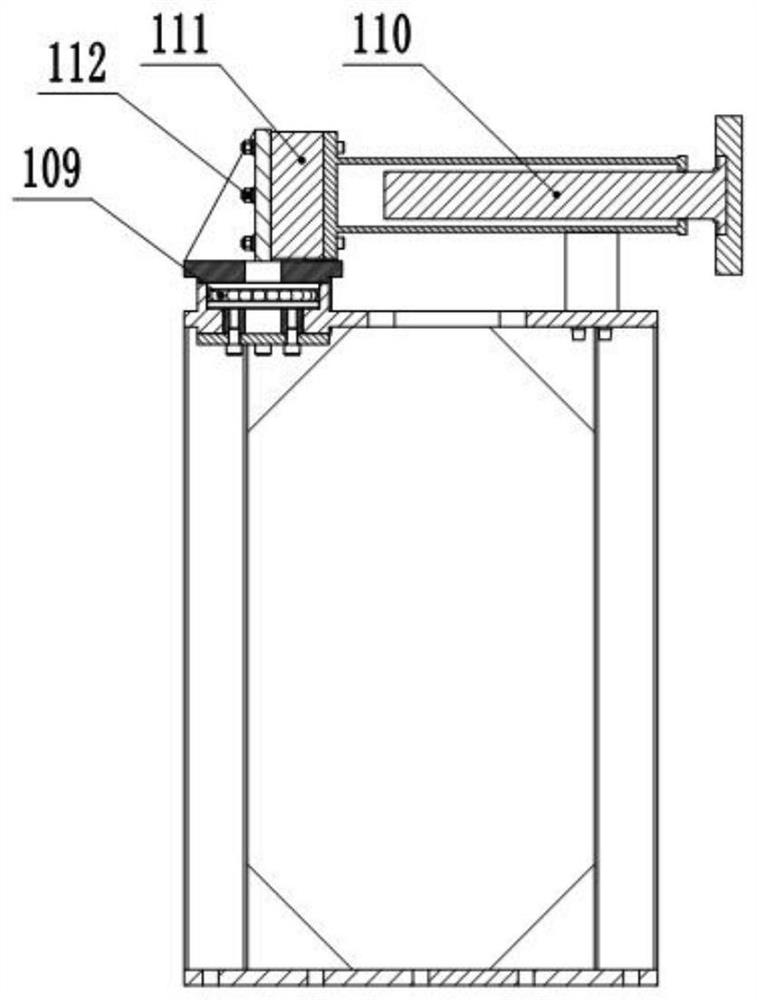

[0051] Such as Figure 1-18 As shown, a fuel supercritical combustion test equipment includes a hydraulic propulsion device 1, a nylon plug 2, a heavy piston installation section 3, a compression tube 4, a compression tube support device 5, a compression tube thrust device 6, and a heavy piston backstop device 7. Experimental cabin 8, experimental cabin support device 9, steel rail 10, high pressure source 11, ball valve 12 and heavy piston 13, the hydraulic propulsion device 1, nylon plug 2, heavy piston installation section 3, heavy piston 13, compression tube 4 , the heavy piston stop device 7 and the experimental cabin 8 are arranged in sequence to form a test line, the heavy piston installation section 3 is provided with the nylon plug 2 near the side of the hydraulic propulsion device 1, and the heavy piston installation section The bottom of 3 communicates with the high pressure source 11 through a ball valve 12, the compression tube 4 is supported by two compression tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com