Hydroxyl strontium phosphate super-long nanowire as well as preparation method and application thereof

A hydroxyphosphoric acid, nanowire technology, applied in nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve problems such as no relevant reports, and achieve the effects of simple process, good flexibility, and high aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing ultra-long strontium hydroxyphosphate nanowires, the preparation steps of which are as follows:

[0024] Under normal temperature stirring, the oleate aqueous solution is added to the strontium salt aqueous solution, and then the phosphate aqueous solution is added under stirring to form a precursor suspension.

[0025] Wherein, the oleate includes but not limited to sodium oleate, potassium oleate and ammonium oleate, and the concentration of the oleate in the precursor suspension can be 0.01-10 mol / L, preferably 0.1-10 mol / L. 3mol / L. The phosphate includes but not limited to sodium phosphate, sodium dihydrogen phosphate, disodium hydrogen phosphate, sodium tripolyphosphate, sodium hexametaphosphate, potassium phosphate, dipotassium hydrogen phosphate, potassium dihydrogen phosphate, potassium tripolyphosphate, hexa Potassium metaphosphate, ammonium phosphate, diammonium hydrogen phosphate, ammonium dihydrogen phosphate, a...

Embodiment 1

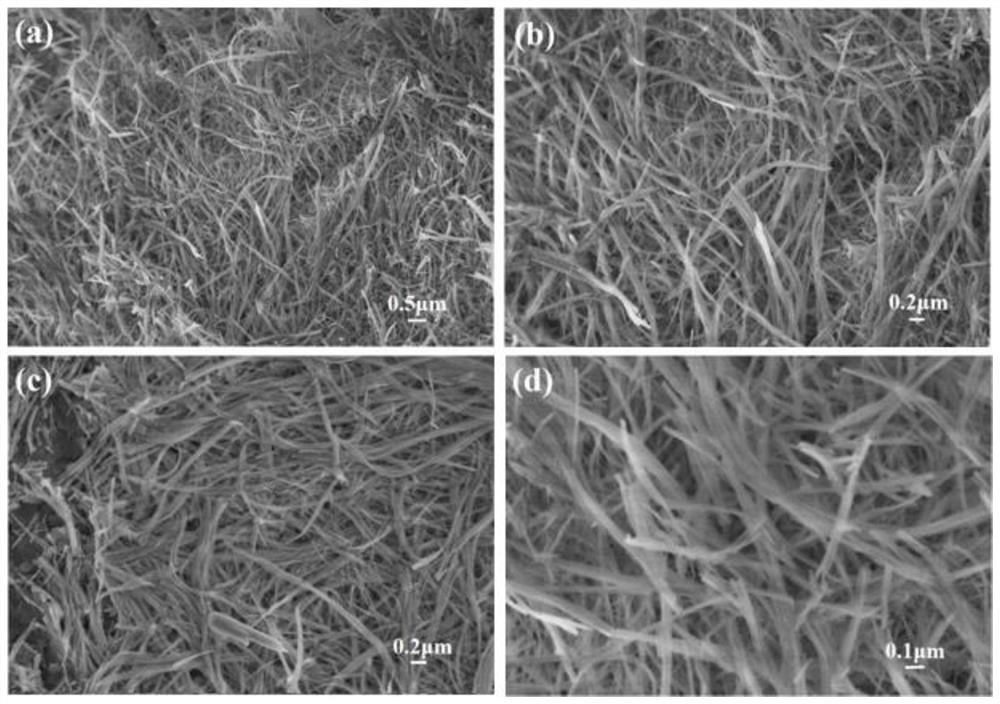

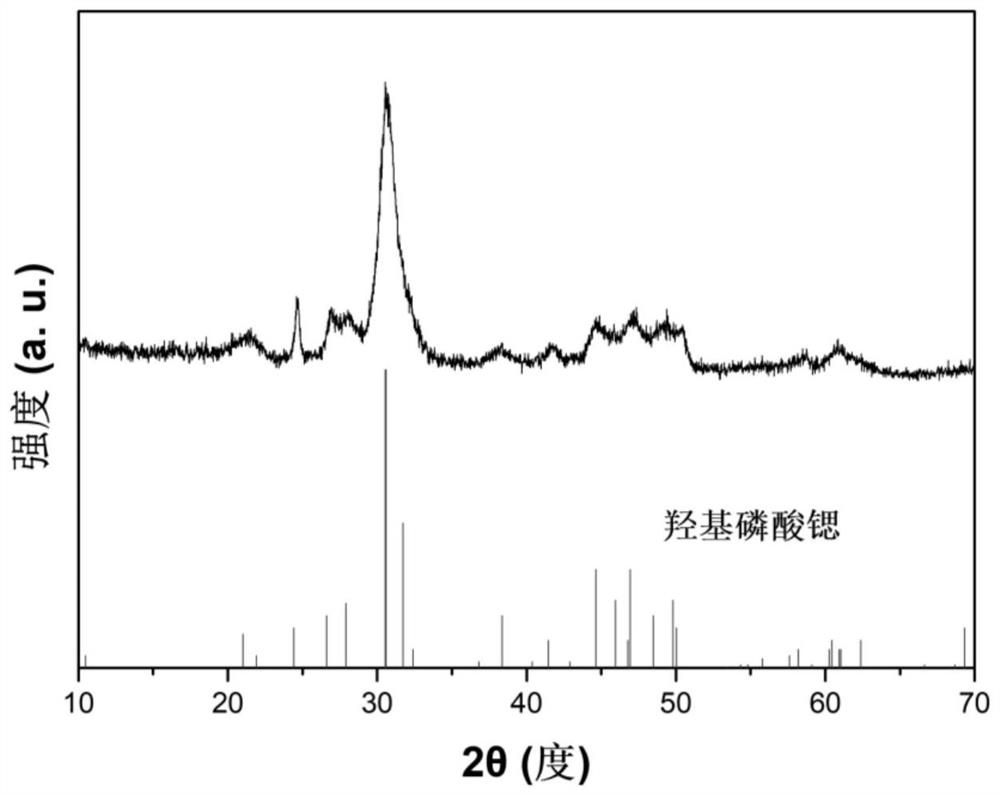

[0039] At room temperature, 0.533 g of SrCl 2 ·6H 2 O was dissolved in 25 ml of deionized water to form solution A; 2.436 g of sodium oleate was dissolved in 25 ml of deionized water to form solution B; after stirring, solution A was added dropwise to solution B, and after stirring at room temperature for 20 minutes , add 25 ml containing 0.281 g NaH 2 PO 4 2H 2 O aqueous solution to obtain a suspension of the reaction precursor, and then transfer the suspension of the reaction precursor to a 100 ml polytetrafluoroethylene-lined stainless steel reactor, seal it, hydrothermally treat it at 180 ° C for 24 hours, and then cool it naturally to room temperature. The product was centrifuged and washed twice with ethanol and deionized water respectively to obtain figure 1 It can be seen that in most cases, a plurality of strontium hydroxyphosphate ultralong nanowires self-assemble into strontium hydroxyphosphate ultralong nanowire bundles along the length direction; X-ray diffrac...

Embodiment 2

[0041] At room temperature, 1.066 g of SrCl 2 ·6H 2 O was dissolved in 25 ml of deionized water to form solution A; 2.436 g of sodium oleate was dissolved in 25 ml of deionized water to form solution B; after stirring, solution A was added dropwise to solution B, and after stirring at room temperature for 20 minutes , add 25 ml containing 0.281 g NaH 2 PO 4 2H 2 O aqueous solution to obtain a suspension of the reaction precursor, and then transfer the suspension of the reaction precursor to a 100 ml polytetrafluoroethylene-lined stainless steel reactor, seal it, hydrothermally treat it at 180 ° C for 24 hours, and then cool it naturally to room temperature. The product was centrifuged and washed twice with ethanol and deionized water respectively to obtain ultra-long nanowires of strontium hydroxyphosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com