Preparation method of strontium-containing phosphate bioactivity conversion coating on titanium surface

A technology of biological activity and phosphate chemistry, which is applied in the field of preparation of strontium-containing phosphate bioactive conversion film on the surface of titanium, can solve the problems of not reaching the nanometer scale, and achieve the promotion of deposition, low energy consumption and production cost, and is beneficial to The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

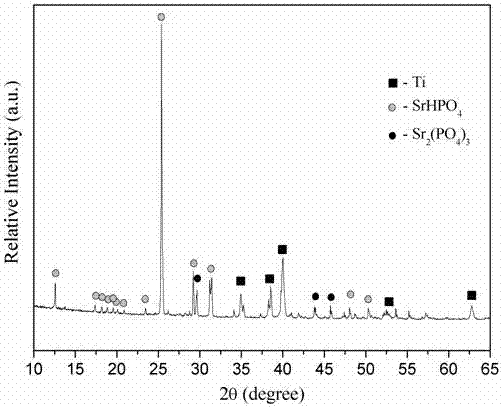

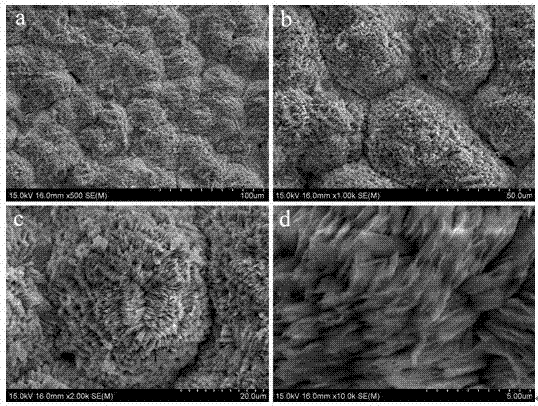

Image

Examples

Embodiment 1

[0025] (1) Preparation of chemical conversion base liquid: sodium dihydrogen phosphate 0.1mol / L, strontium nitrate 0.4mol / L, sodium nitrite 0.05mol / L;

[0026] (2) adjust the pH value of the chemical conversion base solution to be 3.25;

[0027] (3) Using pure titanium as the substrate, pickling with 2wt% hydrofluoric acid at room temperature for 15s, then washing with water, and then activating with 3g / L colloidal titanium solution at room temperature for 30s;

[0028] (4) Soak the treated titanium substrate in the chemical conversion base solution, treat it in an ultrasonic field environment at 65°C for 15 minutes, and then let it stand in a water bath and heat it for 15 minutes;

[0029] (5) Rinse and dry the product obtained in step (4) to obtain a strontium-containing phosphate bioactive conversion film on the titanium surface.

Embodiment 2

[0031] (1) Preparation of chemical conversion base liquid: zinc dihydrogen phosphate 0.1mol / L, strontium nitrate 0.5mol / L, sodium nitrate 0.05mol / L;

[0032] (2) adjust the pH of the chemical conversion base solution to be 3.75;

[0033] (3) Using pure titanium as the substrate, pickling with 2wt% hydrofluoric acid at room temperature for 15s, then washing with water, and then activating with 3g / L colloidal titanium solution at room temperature for 30s;

[0034] (4) Soak the treated titanium substrate in the chemical conversion base solution, treat it in an ultrasonic field environment at 65°C for 20 minutes, and then let it stand in a water bath and heat it for 20 minutes;

[0035] (5) Rinse and dry the product obtained in step (4) to obtain a strontium-containing phosphate bioactive conversion film on the titanium surface.

Embodiment 3

[0037] (1) Preparation of chemical conversion base liquid: sodium dihydrogen phosphate 0.1mol / L, strontium nitrate 0.6mol / L, calcium nitrate 0.05mol / L;

[0038] (2) adjust the pH value of the chemical conversion base solution to 4.50;

[0039] (3) Using pure titanium as the substrate, pickling with 2wt% hydrofluoric acid at room temperature for 20s, then washing with water, and then activating with 3g / L colloidal titanium solution at room temperature for 30s;

[0040] (4) Soak the treated titanium substrate in the chemical conversion base solution, treat it in an ultrasonic field environment at 75°C for 20 minutes, and then let it stand in a water bath and heat it for 20 minutes;

[0041] (5) Rinse and dry the product obtained in step (4) to obtain a strontium-containing phosphate bioactive conversion film on the titanium surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com