Titanium surface micro-nano zinc phosphate strontium chemical conversion film and controllable preparation method thereof

A chemical conversion film and chemical conversion technology, which is applied in the field of micro-nano structure zinc strontium phosphate chemical conversion film on the surface of titanium and its controllable preparation, can solve the problem that it is difficult to form a mixture of zinc strontium phosphate, achieve improved clinical application effect, and simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

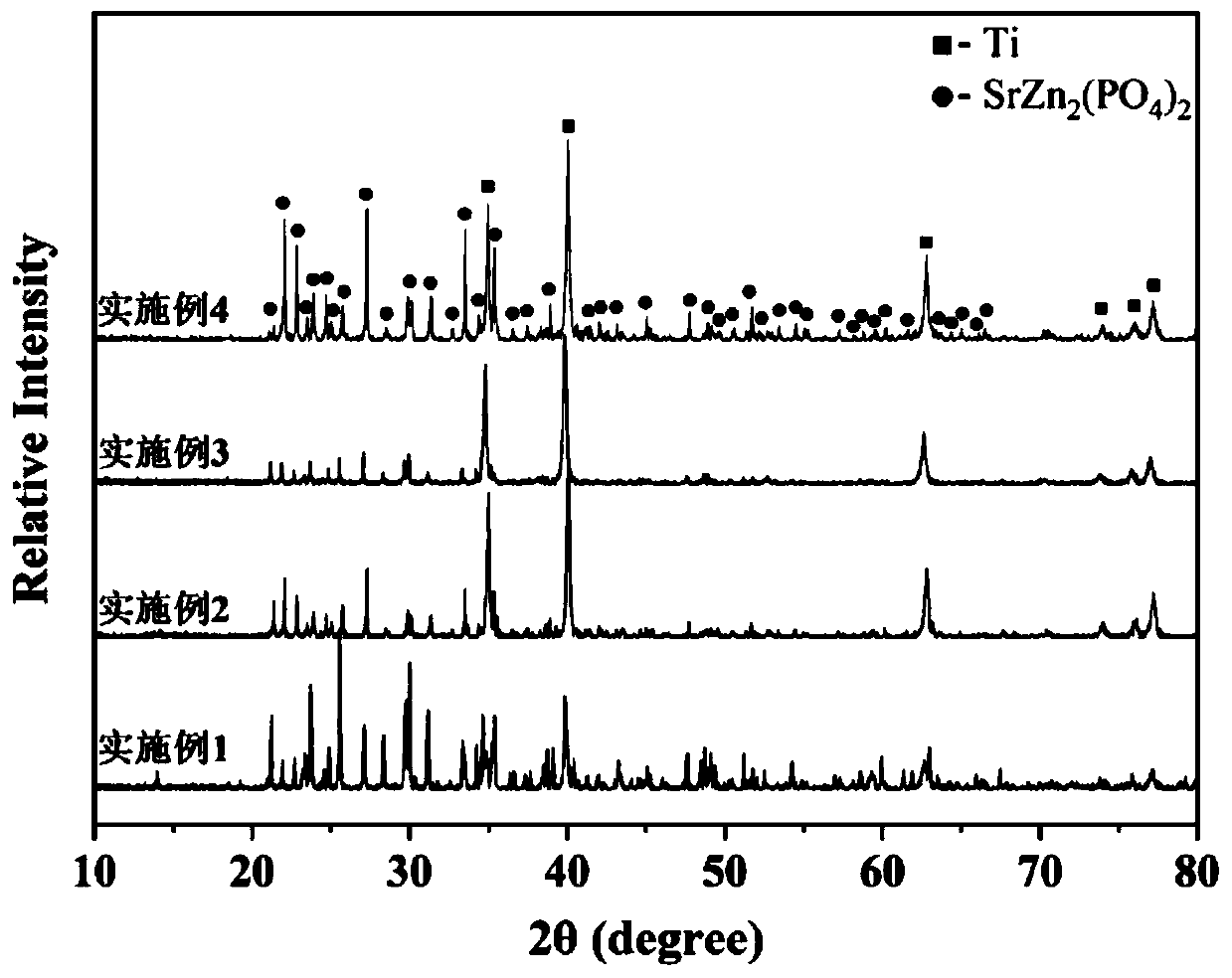

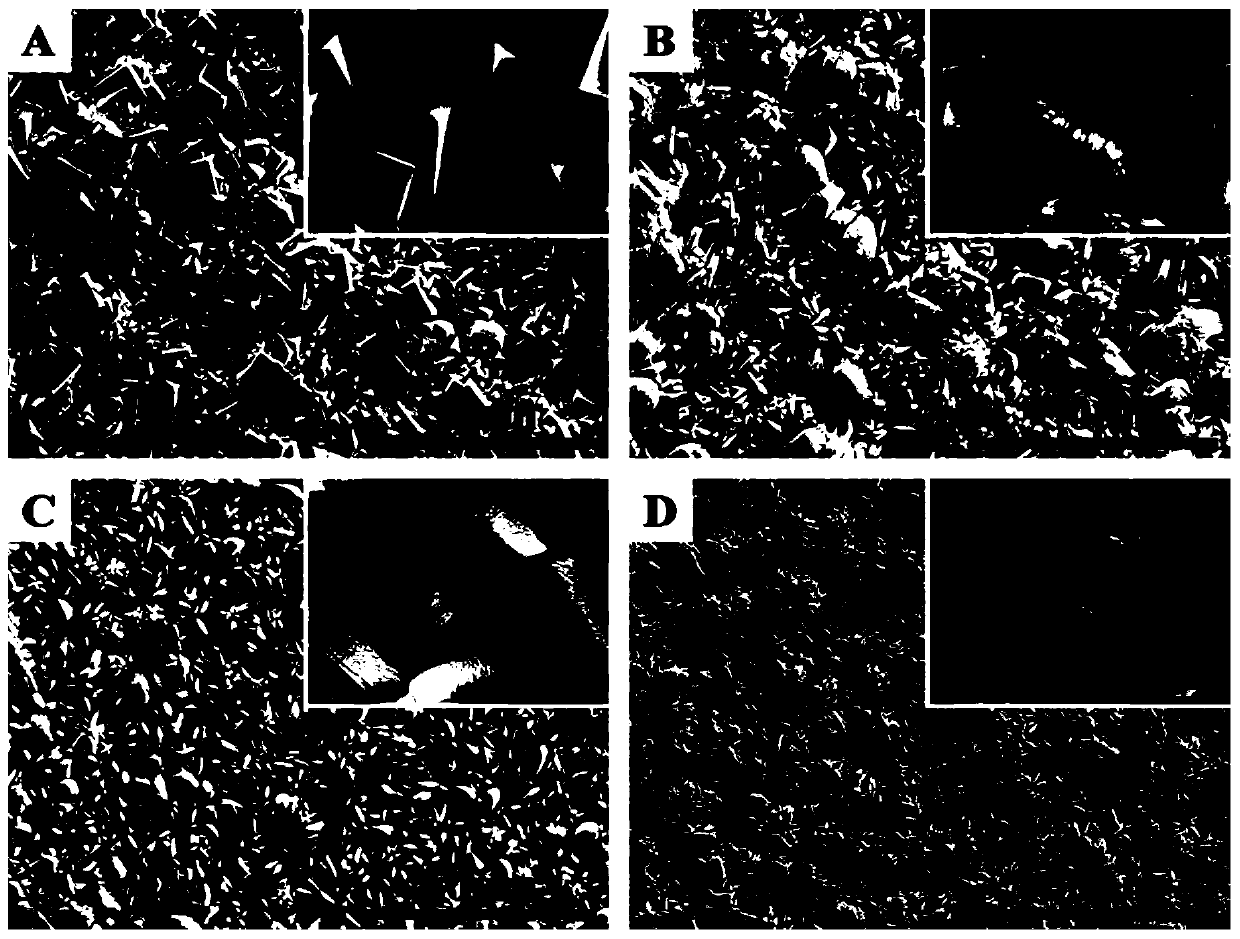

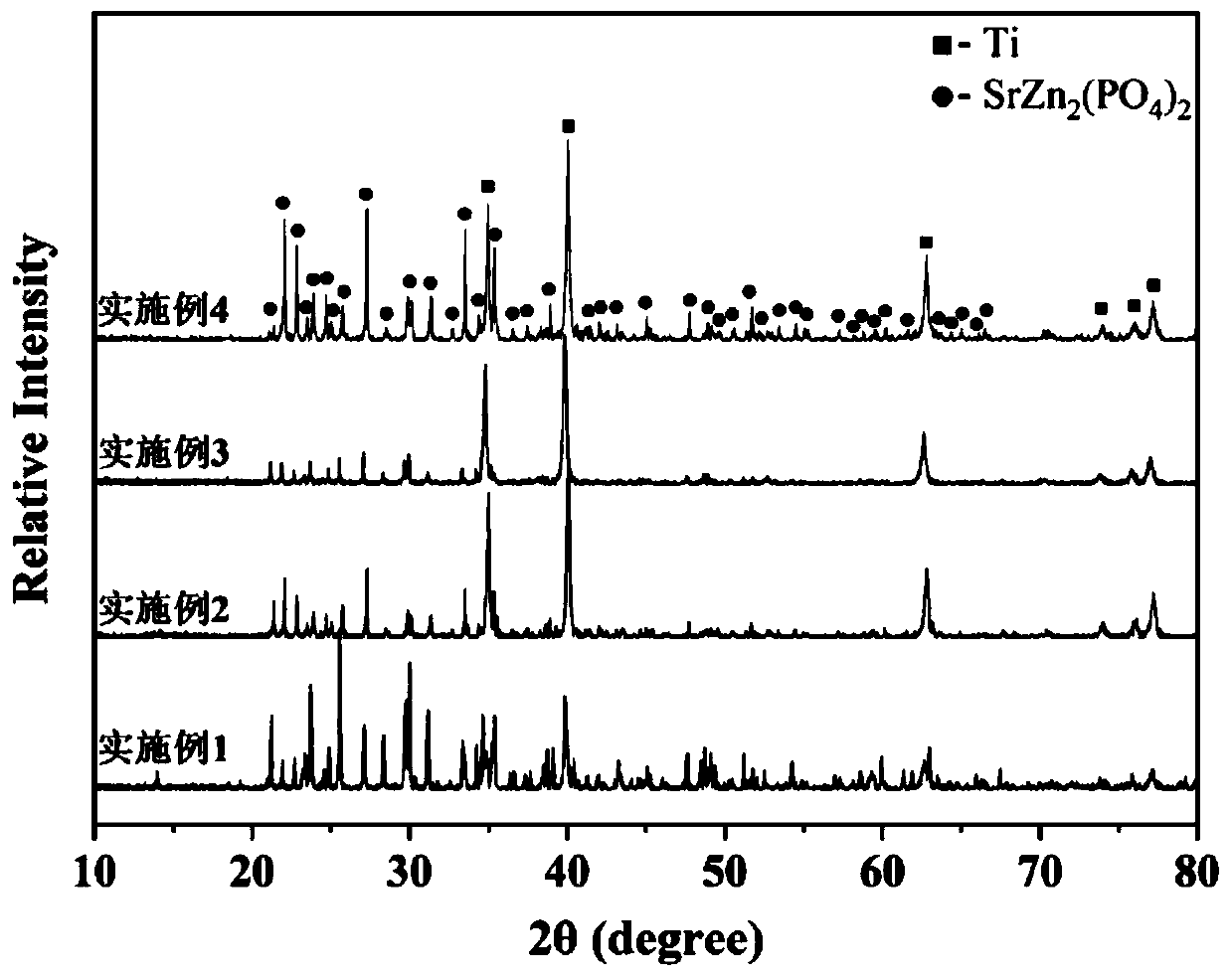

Embodiment 1

[0047] (1) Weigh SrCl 2 ·6H 2 O 32g, NaH 2 PO 4 2H 2 O 14g, Zn(H 2 PO 4 ) 2 2H 2 O 10g, NaNO 3 2g, dissolved in 1L deionized water and mixed evenly to obtain the chemical transformation base liquid;

[0048] (2) Weigh 5g of reduced iron powder, and use 7% v / v H 3 PO 4 After pickling for 5 minutes, add it to the chemical conversion base solution, let it stand at room temperature for aging for 24 hours, and filter the supernatant to obtain the aging solution;

[0049] (3) with 10wt% H 3 PO 4 Or 5mol / L NaOH solution to adjust the pH value of the curing solution to 3.25;

[0050] (4) Clean the polished pure titanium substrate sequentially with acetone, ethanol, and deionized water at room temperature for 10 minutes, then treat it with 2wt% hydrofluoric acid for 30 seconds at room temperature, and place it in 3 g / L colloidal titanium after washing. Activation treatment at room temperature for 30s in the solution;

[0051] (5) Coupling the pure titanium substrate tre...

Embodiment 2

[0054] (1) Weigh SrCl 2 ·6H 2 O 32g, NaH 2 PO 4 2H 2 O 14g, Zn(H 2 PO 4 ) 2 2H 2 O 2g, NaNO 3 2g, dissolved in 1L deionized water and mixed evenly to obtain the chemical transformation base liquid;

[0055] (2) Weigh 5g of reduced iron powder, and use 7% v / v H 3 PO 4 After pickling for 5 minutes, add it to the chemical conversion base solution, let it stand at room temperature for aging for 24 hours, and filter the supernatant to obtain the aging solution;

[0056] (3) with 10wt% H 3 PO 4 Or 1mol / L NaOH solution to adjust the pH value of the curing solution to 3.25;

[0057] (4) Clean the polished pure titanium substrate sequentially with acetone, ethanol, and deionized water at room temperature for 10 minutes, then treat it with 2wt% hydrofluoric acid for 30 seconds at room temperature, and place it in 3 g / L colloidal titanium after washing. Activation treatment at room temperature for 30s in the solution;

[0058] (5) Coupling the pure titanium substrate trea...

Embodiment 3

[0061] (1) Weigh SrCl 2 ·6H 2 O 32g, NaH 2 PO 4 2H 2 O 14g, Zn(H 2 PO 4 ) 2 2H 2 O 1g, NaNO 3 2g, dissolved in 1L deionized water and mixed evenly to obtain the chemical transformation base liquid;

[0062] (2) Weigh 5g of reduced iron powder, and use 7% v / v H 3 PO 4 After pickling for 5 minutes, add it to the chemical conversion base solution, let it stand at room temperature for aging for 24 hours, and filter the supernatant to obtain the aging solution;

[0063] (3) with 10wt% H 3 PO 4 Or 1mol / L NaOH solution to adjust the pH value of the curing solution to 3.25;

[0064] (4) Clean the polished pure titanium substrate sequentially with acetone, ethanol, and deionized water at room temperature for 10 minutes, then treat it with 2wt% hydrofluoric acid for 30 seconds at room temperature, and place it in 3 g / L colloidal titanium after washing. Activation treatment at room temperature for 30s in the solution;

[0065] (5) Coupling the pure titanium substrate trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com