Anticorrosion coating for buried pipeline and preparation method of anticorrosion coating

A technology for buried pipelines and anti-corrosion coatings, applied in anti-corrosion coatings, asphalt coatings, epoxy resin coatings, etc., can solve the problems of complex process, slow progress, asphalt contamination of soil, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for preparing a coating for anticorrosion of buried pipelines, including the following specific steps:

[0038] Step 1: be 25% epoxy resin, 5% auxiliary agent, 5% 70# paraffin wax, 5% curing agent, 3% zinc phosphate, 2% strontium sulfate, 5% hexadecimal Sodium phosphate and 5% sodium pyrophosphate were mixed and stirred at a stirring speed of 250 rpm, and stirred for 35 minutes to obtain a uniform and transparent mixture;

[0039] Step 2: In the stirring state, add 10% by weight talcum powder to the mixture, adjust the rotation speed to 550 rpm, control the cylinder temperature to ≤45°C, and stir for 35 minutes;

[0040] Step 3: Add 35% by weight of modified asphalt liquid, adjust the rotation speed to 750 rpm, stir for 1 hour, check the viscosity≧90s, solid content≧70%, and obtain the finished product.

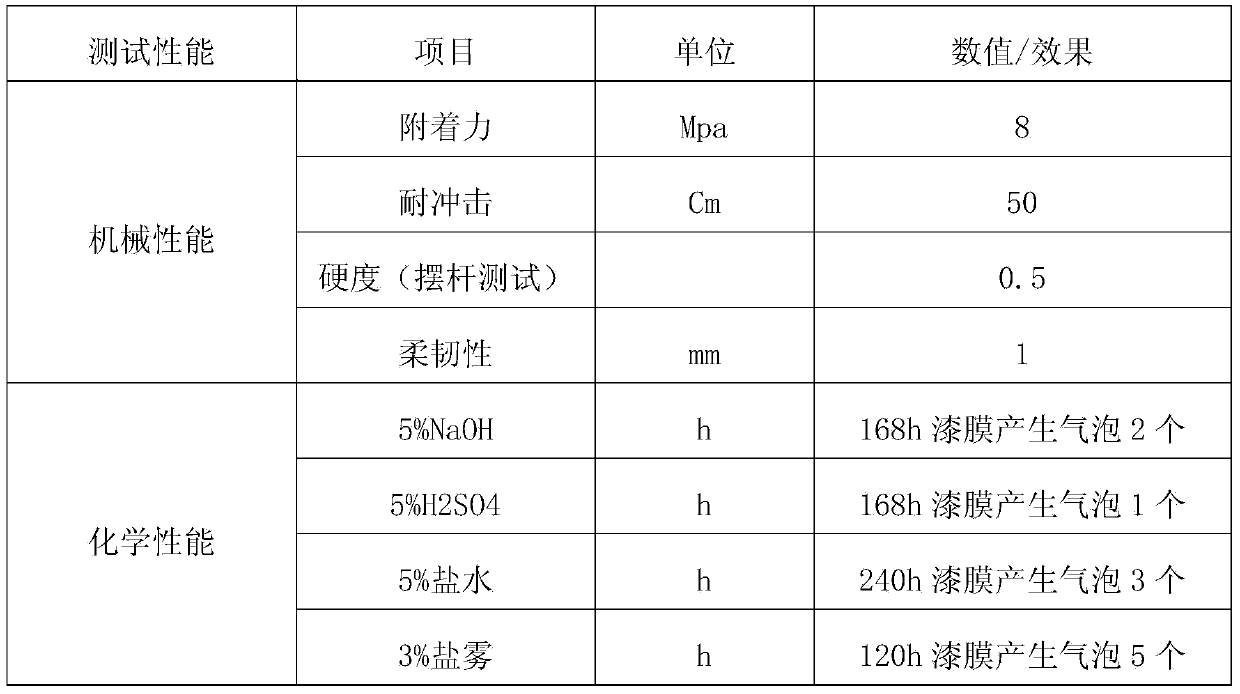

[0041] Effect of use: Make 5 test panels with the above formula, one of which is tested for mechanical properties, and the rest for ...

Embodiment 2

[0045] This embodiment provides a method for preparing a coating for anticorrosion of buried pipelines, including the following specific steps:

[0046] Step one: be 25% epoxy resin, 1% auxiliary agent, 5% 70# paraffin, 13% curing agent, 1% zinc phosphate, 2% strontium sulfate, 3% sodium hexametaphosphate by weight Mix and stir with 5% sodium pyrophosphate, the stirring speed is 350 rpm, and stir for 25 minutes to obtain a uniform and transparent mixture;

[0047] Step 2: In the stirring state, add 10% by weight talcum powder to the mixture, adjust the rotation speed to 650 rpm, control the cylinder temperature to ≤45°C, and stir for 25 minutes;

[0048] Step 3: Add 35% modified asphalt liquid in parts by weight, adjust the rotation speed to 850 rpm, stir for 1 hour, check the viscosity≧90s, solid content≧70%, and obtain the finished product. .

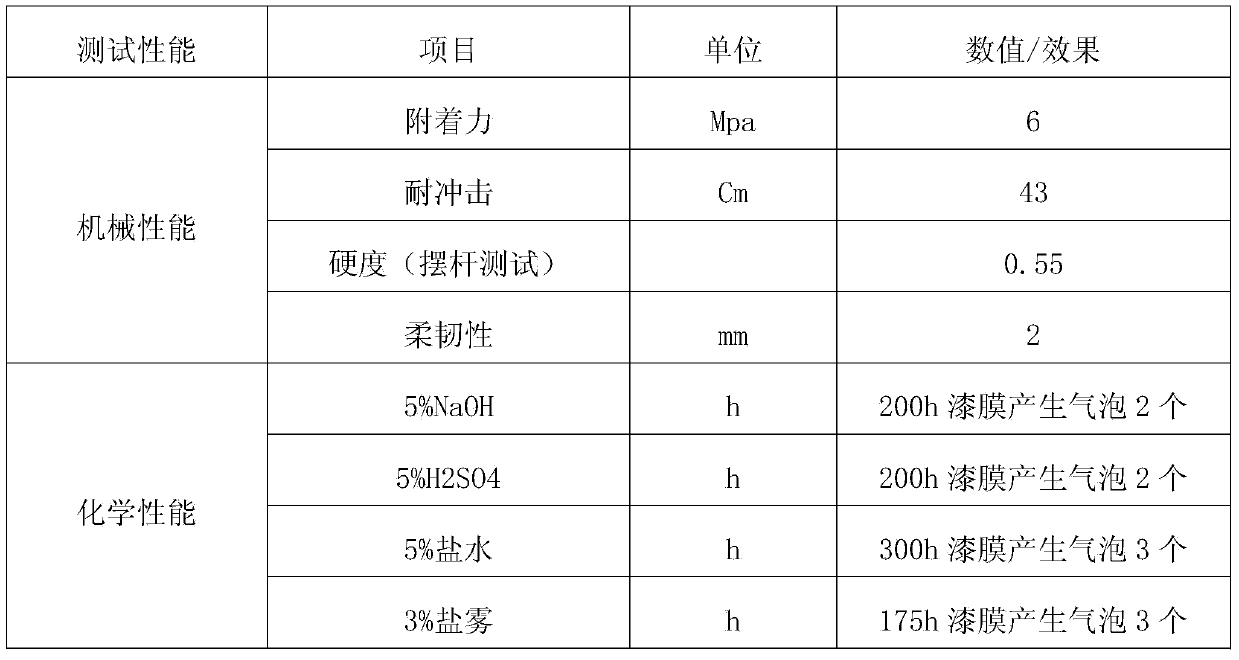

[0049] Effect of use: Make 5 test panels with the above formula, one of which is used for mechanical performance test, and the res...

Embodiment 3

[0053] This embodiment provides a method for preparing a coating for anticorrosion of buried pipelines, including the following specific steps:

[0054] Step one: be 27% epoxy resin, 1% auxiliary agent, 5% 70# paraffin, 5% curing agent, 3% zinc phosphate, 2% strontium sulfate, 4% sodium hexametaphosphate by weight Mix and stir with 8% sodium pyrophosphate, the stirring speed is 300 rpm, and stir for 30 minutes to obtain a uniform and transparent mixture;

[0055] Step 2: In the stirring state, add 10% by weight talcum powder to the mixture, adjust the rotation speed to 600 rpm, control the cylinder temperature to ≤45°C, and stir for 30 minutes;

[0056] Step 3: Add 35% modified asphalt liquid in parts by weight, adjust the rotation speed to 800 rpm, stir for 1 hour, check the viscosity≧90s, solid content≧70%, and obtain the finished product.

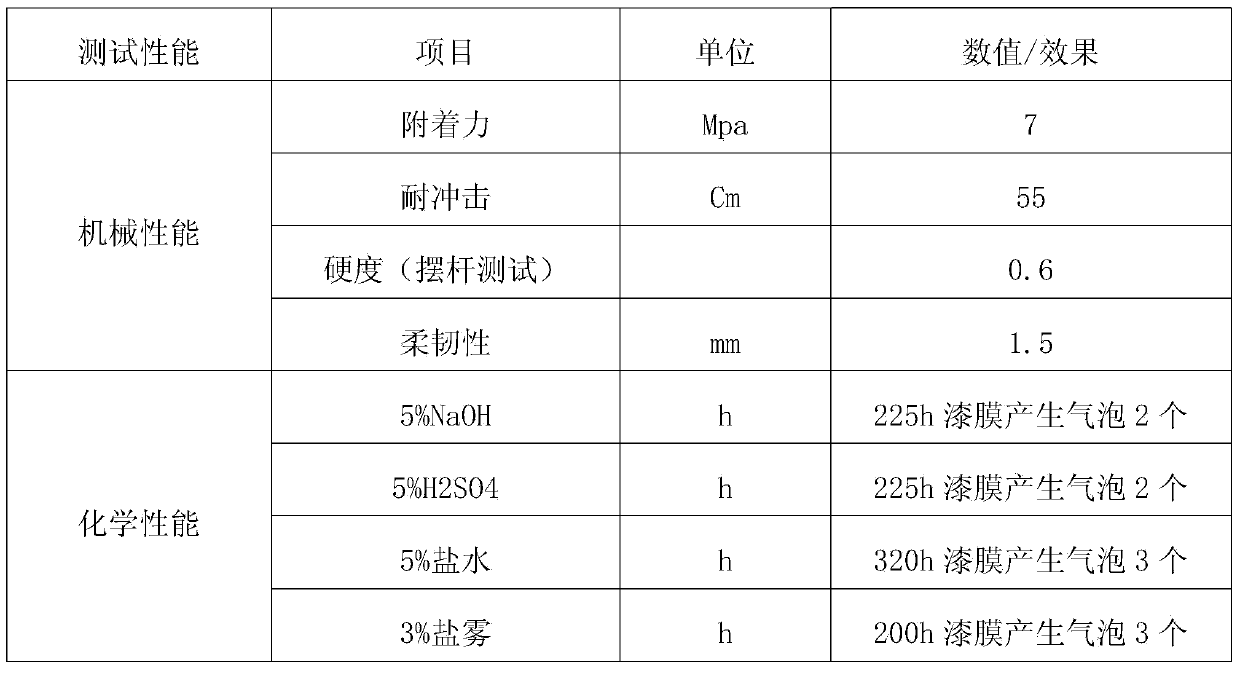

[0057] Effect of use: Make 5 test panels with the above formula, one of which is used for mechanical performance test, and the rest is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com