Development bone cement and its preparation method and use

A bone cement and developing technology, which is used in the field of developing bone cement and its preparation, can solve the problems of weak interaction between bone cement particles and polymer matrix, phase separation between bone cement and contrast agent, and artificial joint wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of above-mentioned visible bone cement, comprises the following steps:

[0024] (1) refinement treatment of the developer, the developer is ground and mixed for 0.5-5 hours, and passed through a 200-mesh sieve;

[0025] (2) Take the sieved developer and the rest of the bone cement powder in a mixer and mix for 3-12 hours;

[0026] (3) Add the mixed bone cement powder to the bone cement liquid for reconciliation. According to the mass ratio, the ratio of powder to liquid is (1.5-2.5):1.

[0027] The aforementioned visible bone cement is used for fracture fixation and bone defect filling caused by osteoporosis.

[0028] The powder polymethyl methacrylate PMMA and benzoyl peroxide are conventional ratios and options, and the liquid liquid is composed of methyl methacrylate monomer, N, N dimethyl p-toluidine and hydroquinone, It is also a conventional ratio and selection, and will not be described here.

Embodiment 1

[0029] Example 1: Using strontium phosphate as a contrast agent to prepare developable bone cement

[0030] (1) Grinding strontium phosphate for 3 hours, passing through a 200-mesh sieve on a vibrating sieve after grinding;

[0031] (2) After sieving, mix strontium phosphate with PMMA and benzoyl peroxide powder in a mixer, mix for 12 hours, and the content of benzoyl peroxide in bone cement powder mass is 0.5%;

[0032] (3) Add the mixed bone cement powder to the bone cement liquid for blending. The ratio of powder to liquid is 2:1 (mass ratio, the same below). After blending evenly, inject or fill it into the desired site.

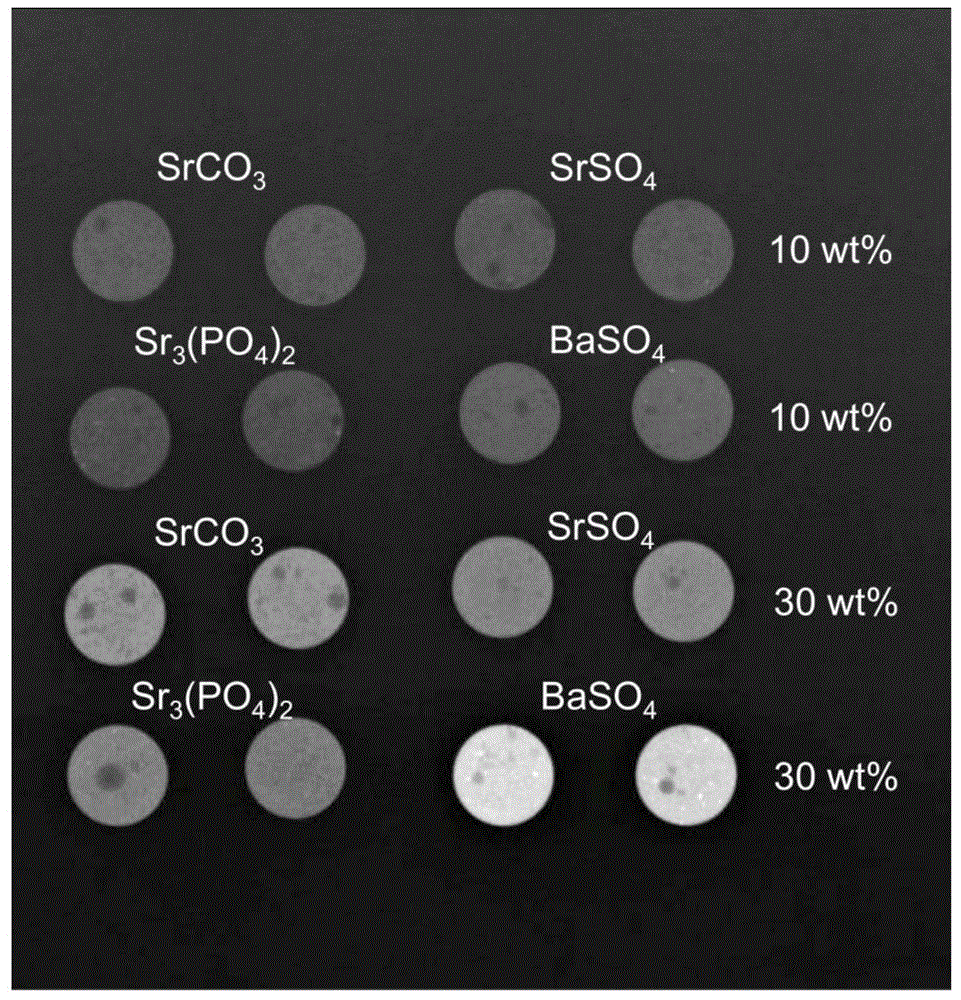

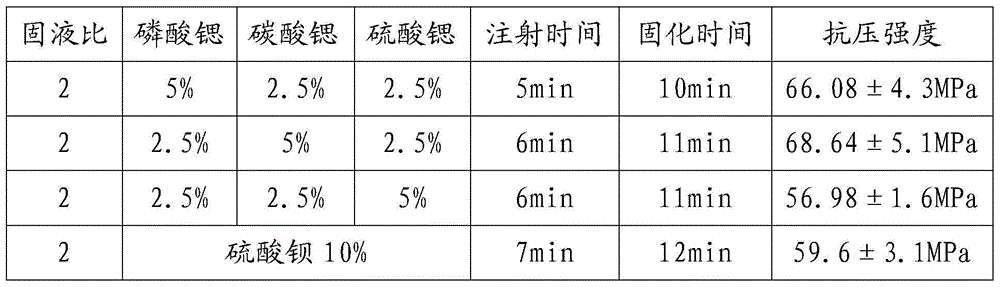

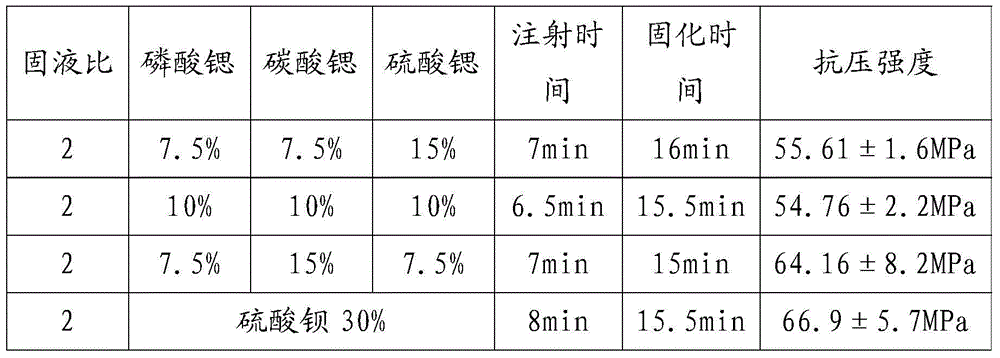

[0033] Bone cement performance comparison is shown in Table 1, from the X-ray photo of its cured body (see figure 1 ) It can be seen that compared with the bone cement added with barium sulfate for development, when the content of strontium phosphate is 10%, there is no difference in brightness, the curing time of bone cement is 12min, and the compressi...

Embodiment 2

[0036] Example 2: Using strontium carbonate as a contrast agent to prepare developable bone cement

[0037] (1) Grinding strontium carbonate for 3 hours, after grinding, cross a 200-mesh sieve on a vibrating sieve;

[0038] (2) After sieving, strontium carbonate, PMMA, and benzoyl peroxide powder were mixed in a mixer, and mixed for 12 hours, and the content of benzoyl peroxide accounting for the bone cement powder mass was 0.5%;

[0039] (3) Add the mixed bone cement powder to the bone cement liquid for blending. The ratio of powder to liquid is 2:1. After blending evenly, inject or fill into the desired part.

[0040] Bone cement performance comparison is shown in Table 1, from the X-ray photograph of bone cement (see figure 1 ) It can be seen that compared with the bone cement added with barium sulfate for development, when the content of strontium carbonate is 10%, there is no difference in brightness, the curing time of bone cement is 14.5min, 2min longer, and the compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com