Surface polymer remover of electrode needle for tantalum capacitor and method for removing surface polymer of electrode needle for tantalum capacitor

A technology for tantalum capacitors and electrode needles, which is applied in the field of polymer remover and its removal on the surface of electrode needles for tantalum capacitors. It can solve the problems of poor conductivity and increased use costs, and achieve accurate stripping, lower use costs, and faster processing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

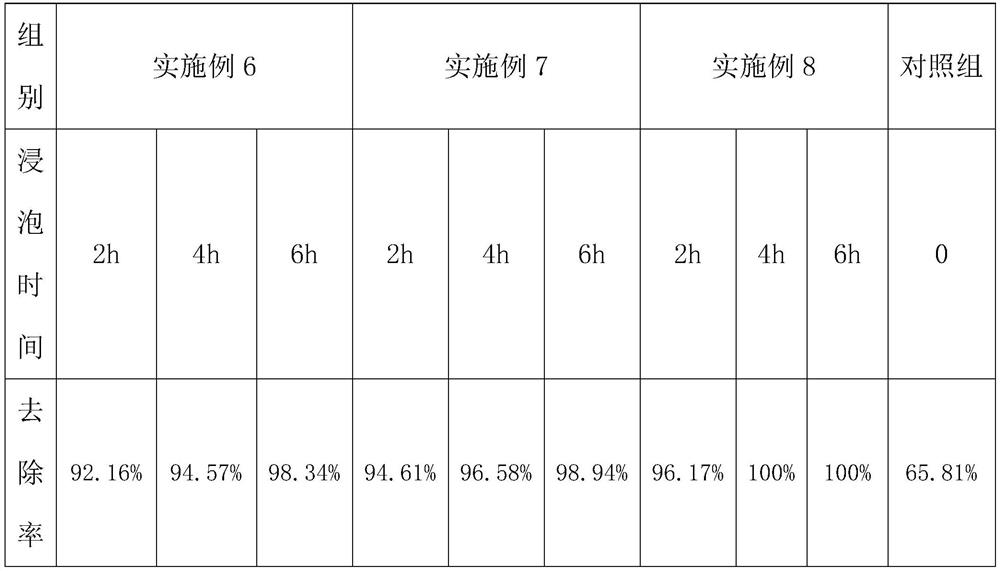

Examples

Embodiment 1

[0025] This embodiment discloses a polymer remover on the surface of electrode needles for tantalum capacitors, which includes the following components in parts by weight: 20 parts of softener, 12 parts of surfactant, 24 parts of inorganic acid, 2 parts of coupling agent, and 4 parts of emulsifier share.

[0026] Wherein, the softening agent includes the following raw materials in parts by weight: 30 parts of sodium lauryl sulfate, 10 parts of polyethylene glycol, 5 parts of diethylene glycol monobutyl ether, 1 part of N-methylpyrrolidone, defoamer 0.6 part, the balance is deionized water; Surfactant comprises anionic surfactant and nonionic surfactant that weight ratio is (3:4); Described mineral acid comprises methanesulfonic acid, phosphoric acid, hydrochloric acid, hydrobromic acid , tartaric acid and acetic acid, and proportioned according to the following mass ratio: 20% methanesulfonic acid, 18% phosphoric acid, 6% hydrochloric acid, 12% hydrobromic acid, 12% tartaric a...

Embodiment 2

[0033] This embodiment discloses a polymer remover on the surface of electrode needles for tantalum capacitors. Its formula ratio and preparation method are basically the same as those in Example 1. The only difference is that the remover includes the following components in parts by weight: softener 35 parts, 19 parts of surfactant, 36 parts of inorganic acid, 4 parts of coupling agent, 8 parts of emulsifier.

Embodiment 3

[0035] This embodiment discloses a polymer remover on the surface of electrode needles for tantalum capacitors. Its formula ratio and preparation method are basically the same as those in Example 1. The only difference is that the remover includes the following components in parts by weight: softener 50 parts, 26 parts of surfactant, 48 parts of inorganic acid, 6 parts of coupling agent, 12 parts of emulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com