Production method and device of electronic components

A technology for producing electronic parts and rolls, which is applied in the field of producing winding electronic parts, can solve the problems such as the difficulty in improving the electrical characteristics of electrolytic capacitors of electronic parts, and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

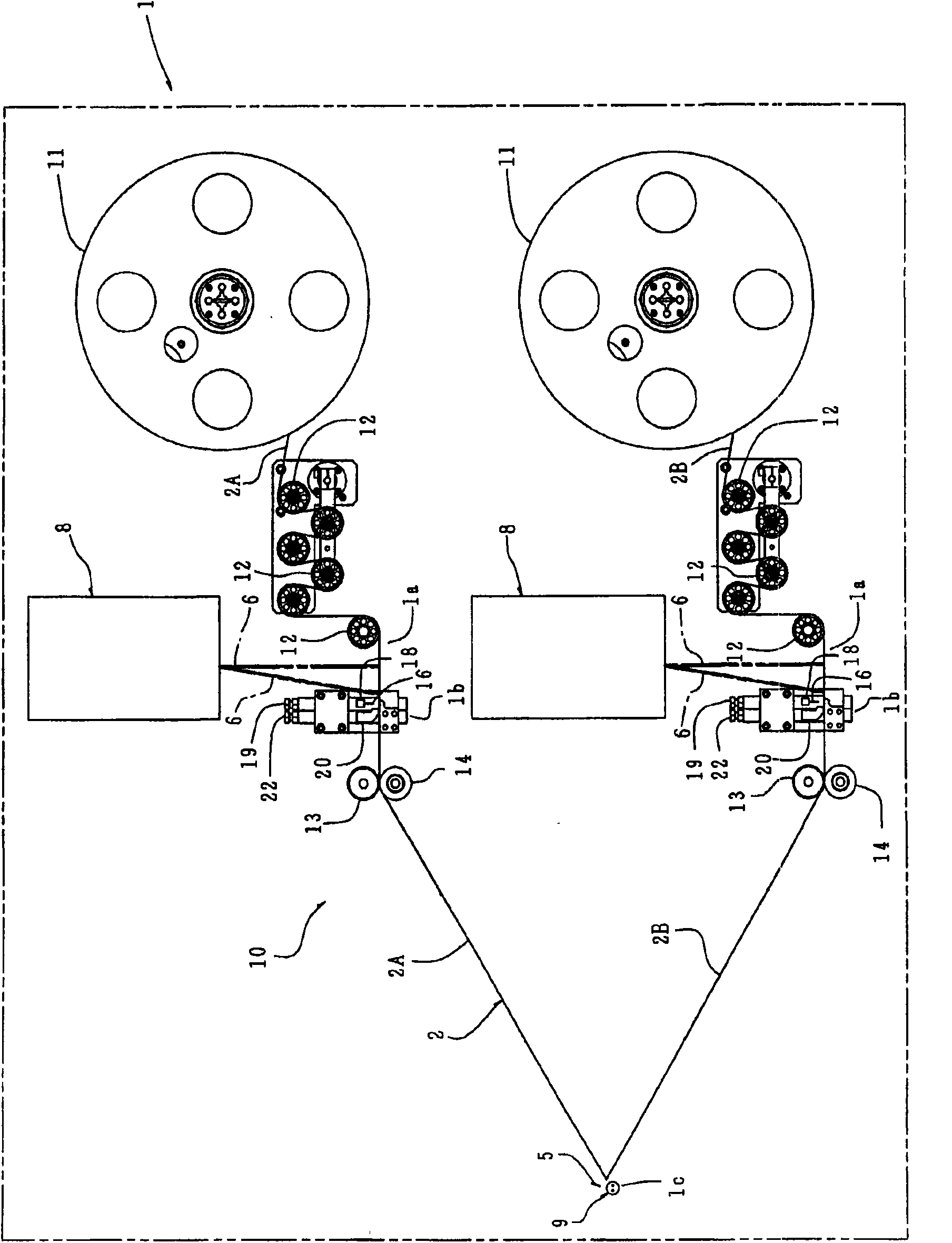

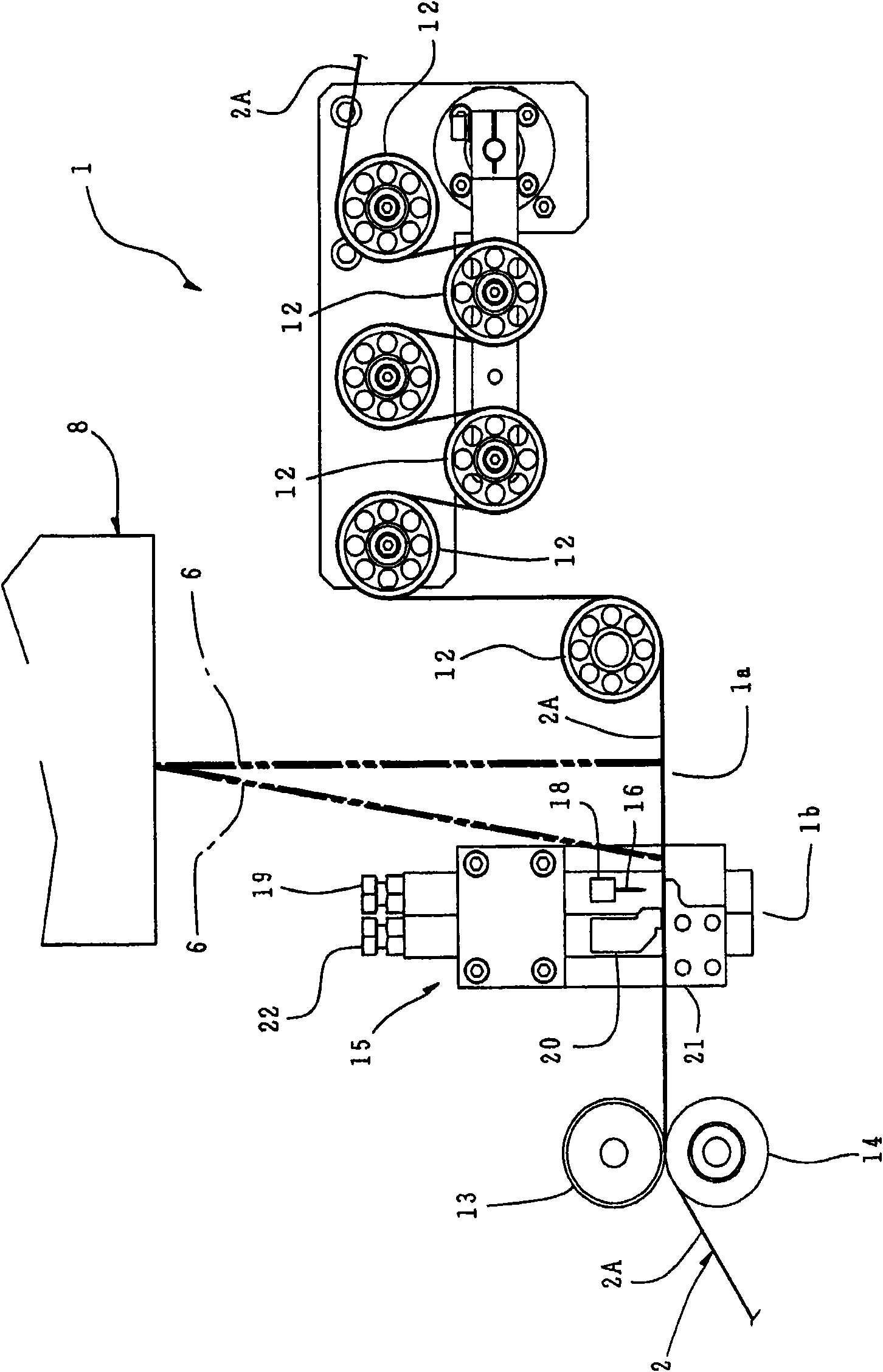

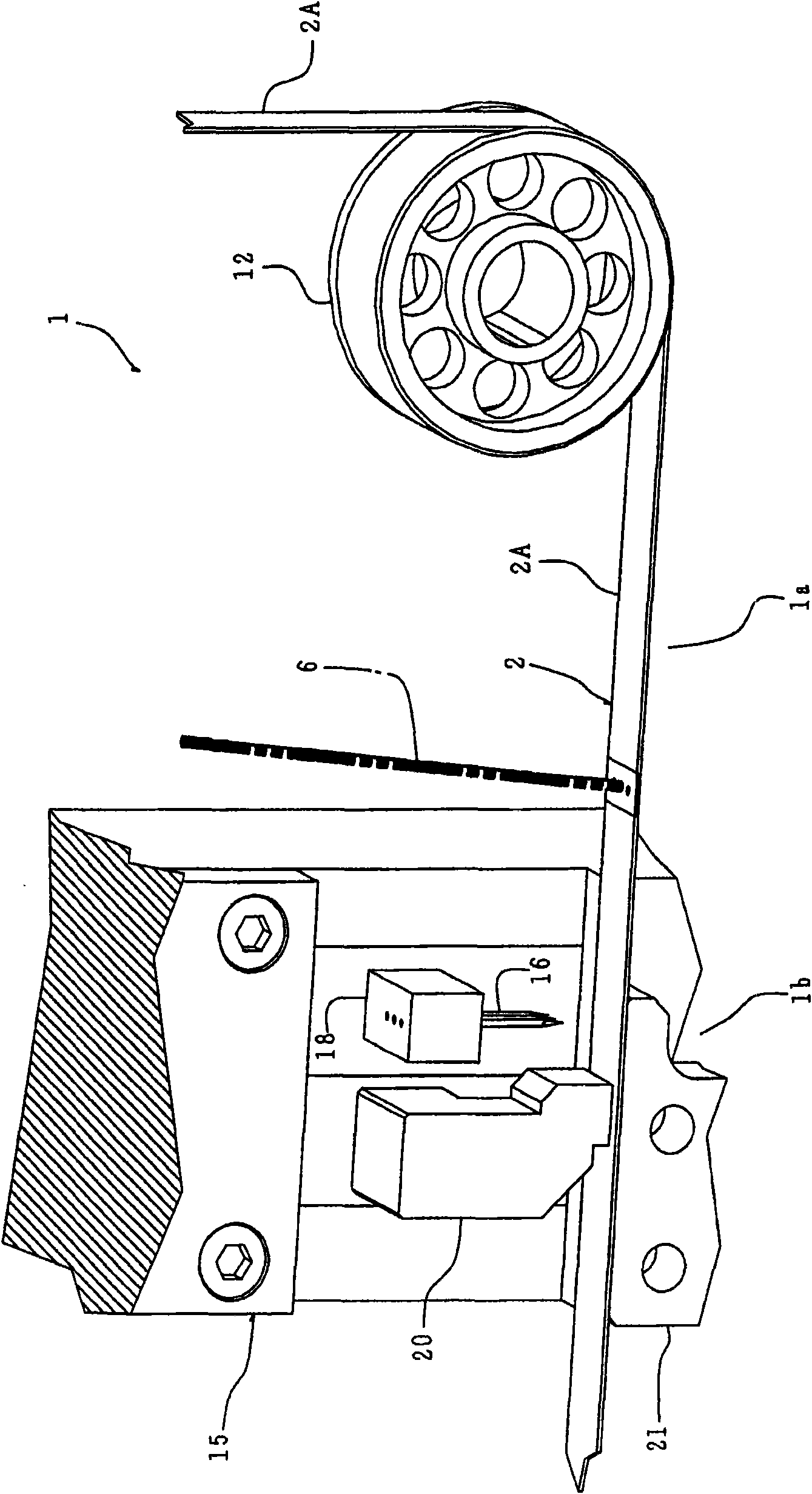

[0050] The present invention will be described in detail below with reference to the accompanying drawings. refer to Figure 1-5 , as an example, an apparatus 1 for producing an electronic part as a wound-type electrolytic capacitor 5 is equipped with a laser irradiation apparatus 8 for irradiating a laser beam to an electrode foil 2 to peel and remove an etching layer or coating from the electrode foil 2. layer (hereinafter referred to as "forming film 2a") ( Figure 6-8 ) for while the electronic parts production apparatus 1 is conveying a plurality of electrode foils 2 (2A, 2B) and a plurality of release papers 3 (3A, 3B) and winding the electrode foils 2 and the release paper 3 so as to wrap the lead terminals 4 ( 4A, 4B) while the joint 4a of the electrode foil 2 is attached to the electrode foil 2, before the electrode foil 2 is pierced with a piercing needle to attach the joint of the lead terminal, a hole is formed in the electrode foil 2 or a hole is formed in the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com