Method for producing microcarriers

A technology of microcarriers and ontology, applied in the field of microcarriers, can solve problems such as separation and error, and achieve the effect of improving mechanical properties and reliable analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

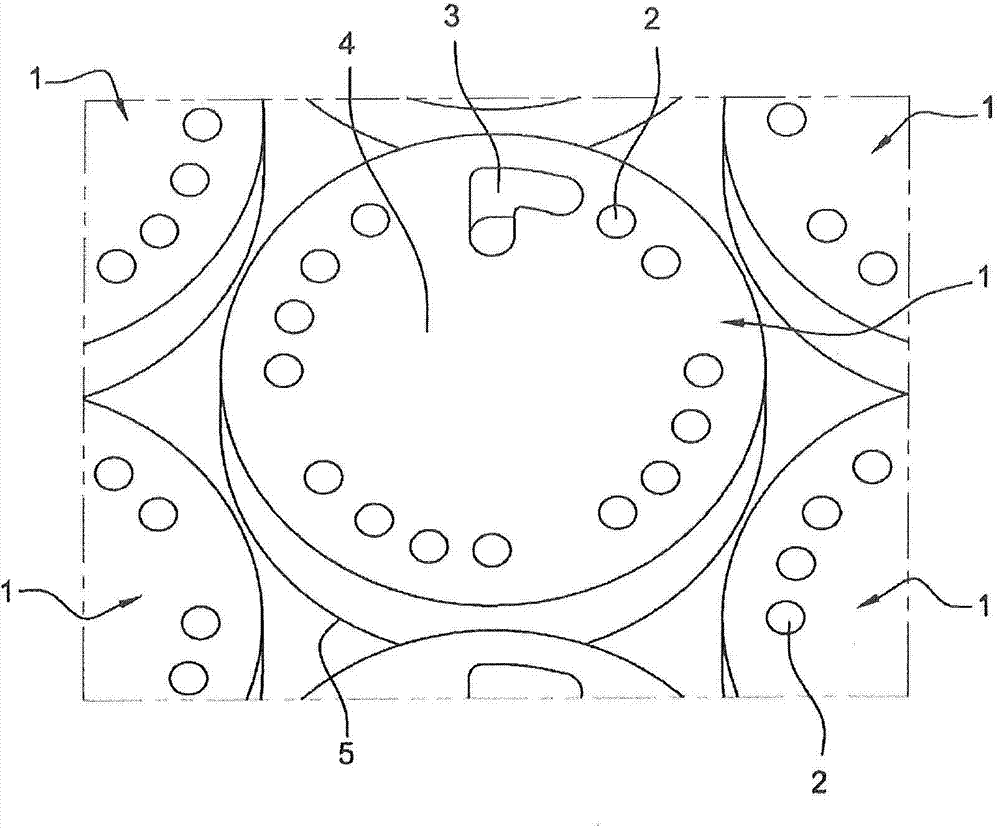

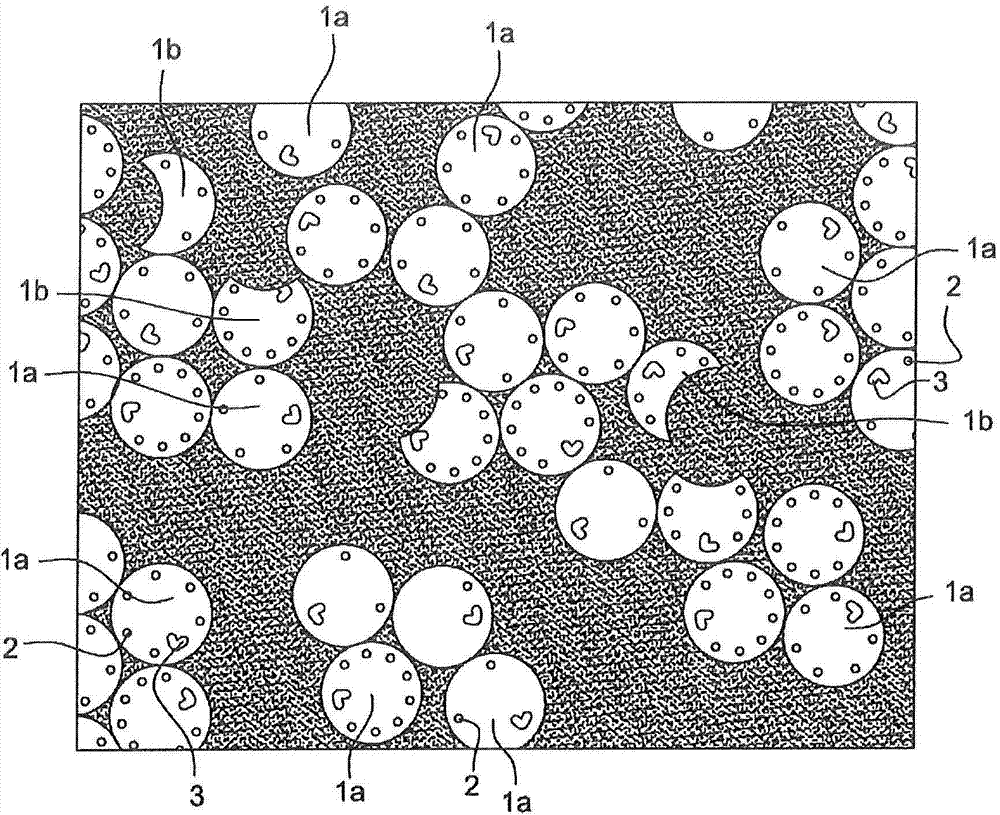

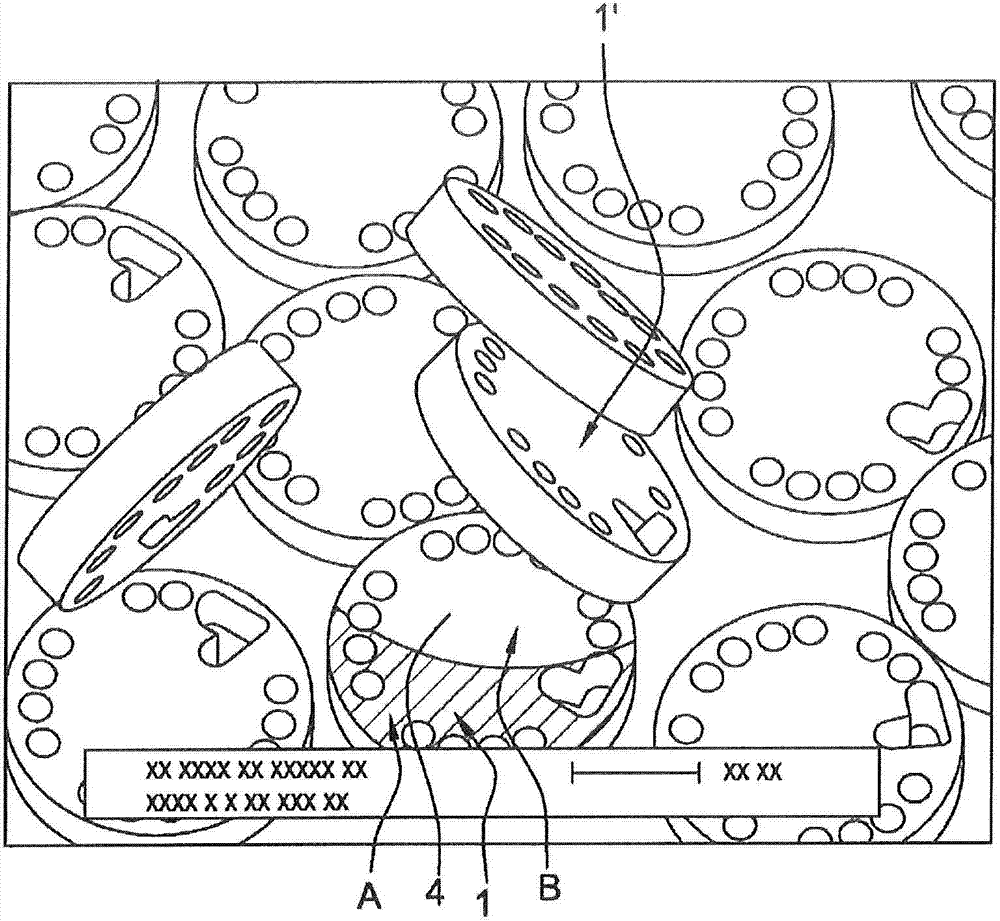

[0057] The following will refer to Figures 6 to 17 Methods of making microcarriers according to the invention are described. The method comprises the following sequential steps:

[0058] first step, such as Figure 4 As shown, there is provided a wafer 6 having a sandwich structure, the wafer 6 comprising a bottom layer 7, a top layer 8 and an insulating layer 9 between said bottom layer and top layer 7,8.

[0059] For example, the wafer 6 is an SOI (silicon on insulator) wafer having a bottom layer 7 with a diameter of 100 mm and a thickness of 380 μm, an insulating layer 9 with a thickness of 1 μm and a top layer 8 with a thickness of 10 μm. The top layer 8 and the bottom layer 7 are made of monocrystalline silicon, and the insulating layer 9 is made of silicon dioxide.

[0060] The second step, such as Figure 5 As shown, a photoresist layer 10 is applied on top layer 8 . In order to outline the surface of the microcarriers, the photoresist layer 10 is irradiated with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com