Method for improving specific volume of low pressure corrosion aluminum foil

A technology for corroding aluminum foil and aluminum foil, applied in capacitors, capacitor manufacturing, metal surface removal regulations, etc., can solve the problem of uniformity of corrosion hole distribution, corrosion foil expansion efficiency, dispersion in corrosive liquid or adsorption on aluminum foil surface, aluminum foil And the problem of uneven current distribution of graphite plates, to achieve the effect of easy and uniform growth, reduction of adsorption, and improvement of current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

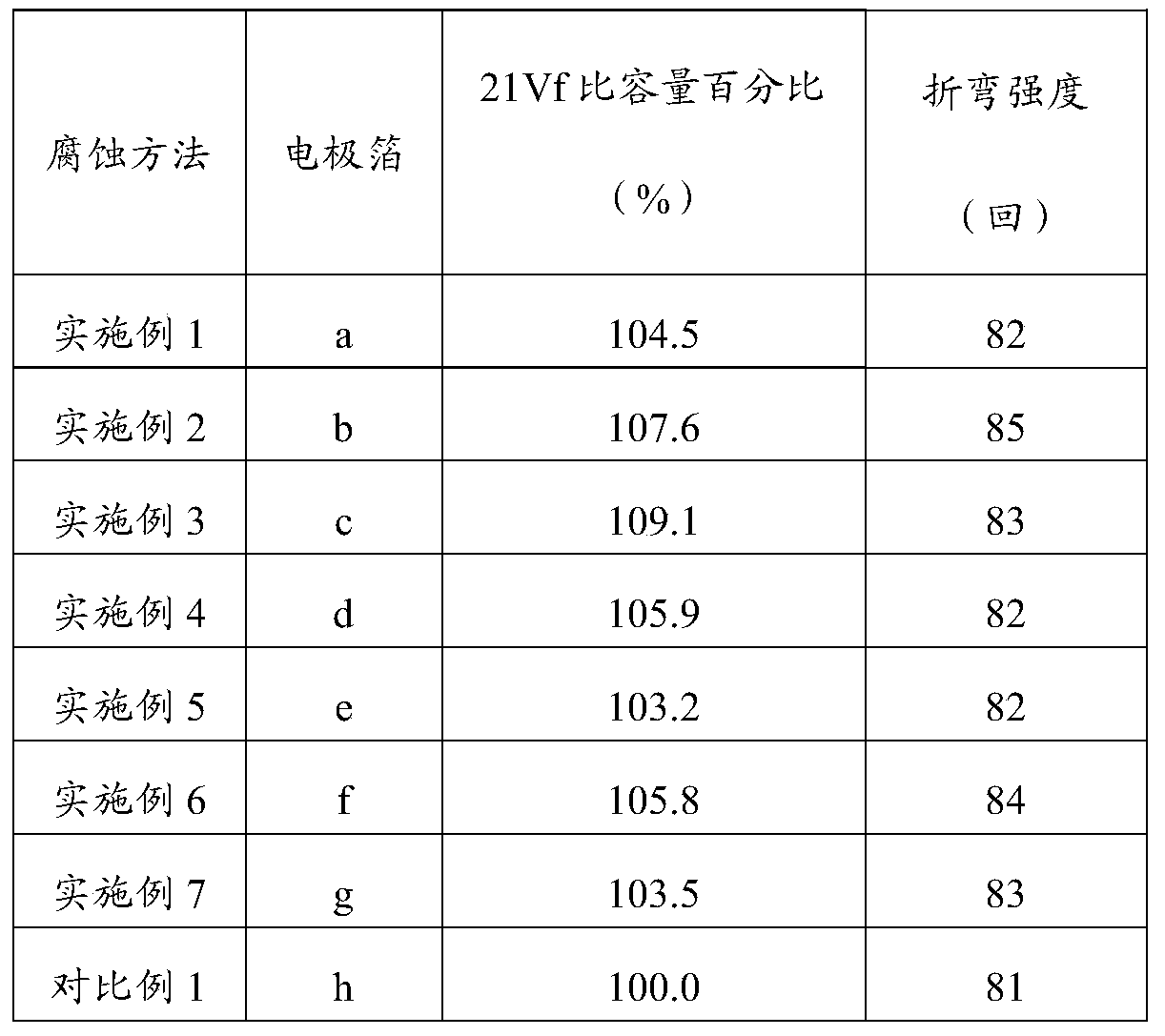

Examples

Embodiment 1

[0055] (1) Pretreatment

[0056] Soak the aluminum foil in an aqueous phosphoric acid solution containing 3wt% phosphoric acid at 60°C for 60 seconds, and wash it with industrial water at room temperature after taking it out;

[0057] (2) Hole corrosion

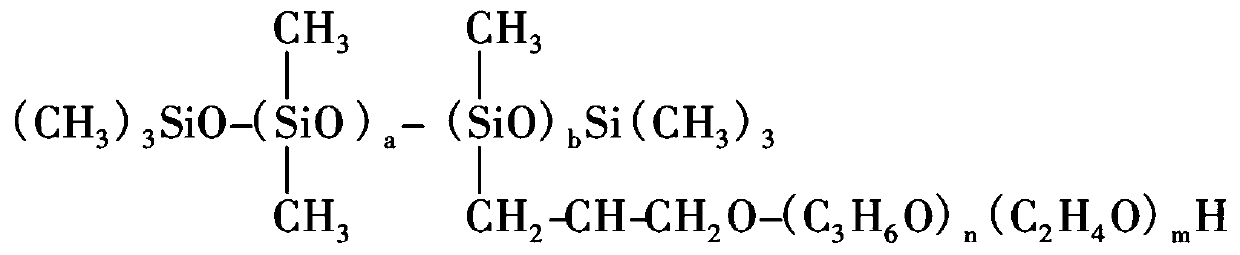

[0058] Place the aluminum foil treated in step (1) at 30°C in an aqueous solution containing 10wt% hydrochloric acid, 0.06wt% sulfuric acid, 0.6wt% aluminum trichloride and 3ppm emulsion type polyether-siloxane copolymer organosilicon foam breaker Corrosion of holes is carried out in the medium, the loading waveform is a sine wave, and the current density is 0.3A / cm 2 , the power-on time is 30 seconds, and the power-on frequency is 30Hz. After taking it out, wash it with industrial water at room temperature;

[0059] (3) processing

[0060] The aluminum foil treated in step (2) is placed in an aqueous solution containing 1 wt% ammonium dihydrogen phosphate at 90°C for intermediate treatment, and the treatment time is 60 se...

Embodiment 2

[0069] Except that the concentration of the emulsion-type polyether-siloxane copolymer organosilicon foam breaker in the aqueous solution in steps (2) and (4) is 30 ppm, the others are the same as in Example 1.

Embodiment 3

[0071] Except that the concentration of the emulsion type polyether-siloxane copolymer organosilicon foam breaker in the aqueous solution is 150ppm in steps (2) and (4), the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com