Manufacturing method of AlGaInP light-emitting diode

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of not being suitable for small-sized light-emitting diodes, reducing the luminous efficiency of small-sized chips, reducing the light-emitting area of the front surface, etc., and achieving optimal current distribution. , improve light efficiency, avoid damage to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

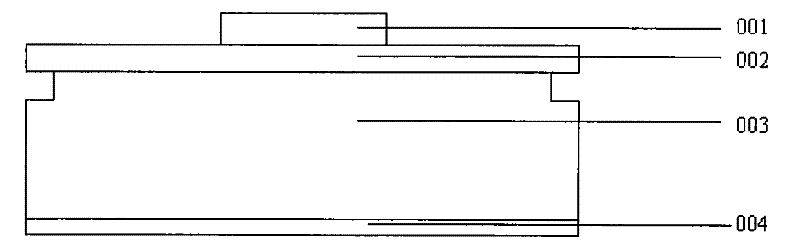

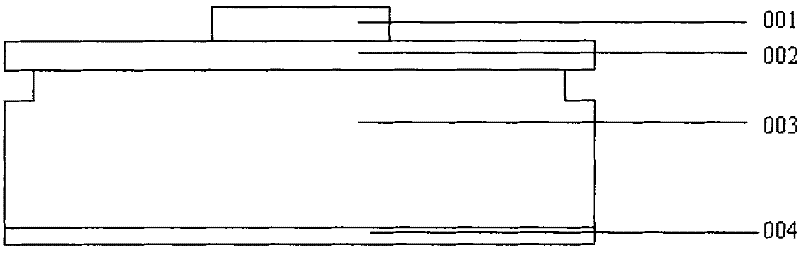

Image

Examples

Embodiment 1

[0022] Step 1: half-cut the AlGaInP light-emitting diode chip by contact scribing process, and the half-cut depth is 40-60um;

[0023] Step 2: Apply photoresist evenly on the back of the chip, and bake on a hot plate until the glue is dry;

[0024] Step 3: configure ammonia water corrosion solution, the ammonia water corrosion solution adopts ammonia water: hydrogen peroxide: water volume ratio is 1: 2: 1;

[0025] Step 4: Corrode the chip in the ammonia solution for 60 seconds with a flower basket;

[0026] Step 5: Rinse the chip with deionized water after corrosion;

[0027] Step 6: remove the photoresist on the back of the chip;

[0028] Step 7: Dry the chip with dry nitrogen.

[0029] sample

Brightnessmcd(20mA)

uncorroded

153.8

corrosion

158.6

[0030] Table 1: Comparison of optoelectronic performance parameters of chips

[0031] Referring to the experimental data in Table 1, the light intensity of the chip is 3.1% higher th...

Embodiment 2

[0033] Step 1: half-cut the AlGaInP light-emitting diode chip by contact scribing process, and the half-cut depth is 40-60um;

[0034] Step 2: Apply photoresist evenly on the back of the chip, and bake on a hot plate until the glue is dry;

[0035] Step 3: configure ammonia water corrosion solution, the ammonia water corrosion solution adopts ammonia water: hydrogen peroxide: water volume ratio is 1: 2: 1;

[0036] Step 4: Corrode the chip in the ammonia solution for 90 seconds with a flower basket;

[0037] Step 5: Rinse the chip with deionized water after corrosion;

[0038] Step 6: remove the photoresist on the back of the chip;

[0039] Step 7: Dry the chip with dry nitrogen.

[0040] sample

Brightnessmcd(20mA)

uncorroded

152

corrosion

165.4

[0041] Table 2: Comparison of optoelectronic performance parameters of chips

[0042] Referring to the experimental data in Table 2, the light intensity of the chip is 8.8% higher than...

Embodiment 3

[0044] Step 1: half-cut the AlGaInP light-emitting diode chip by contact scribing process, and the half-cut depth is 40-60um;

[0045] Step 2: Apply photoresist evenly on the back of the chip, and bake on a hot plate until the glue is dry;

[0046] Step 3: configure ammonia water corrosion solution, the ammonia water corrosion solution adopts ammonia water: hydrogen peroxide: water volume ratio is 1: 2: 1;

[0047] Step 4: Corrode the chip in the ammonia solution for 120 seconds with a flower basket;

[0048] Step 5: Rinse the chip with deionized water after corrosion;

[0049] Step 6: remove the photoresist on the back of the chip;

[0050] Step 7: Dry the chip with dry nitrogen.

[0051] sample

Brightnessmcd(20mA)

uncorroded

152.7

corrosion

175

[0052] Table 3: Comparison of optoelectronic performance parameters of chips

[0053] Referring to the experimental data in Table 3, the light intensity of the chip is 14.6% higher th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com