Method for enlarging surface area of ultrahigh voltage electrode foil by corrosion

An electrode foil and ultra-high voltage technology, which is applied in the direction of removing regulations on metal surfaces, can solve the problems of enlarged surface area of aluminum foil and lack of electrochemical treatment methods for electrode foils, and achieves the effects of high specific volume, high strength, and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

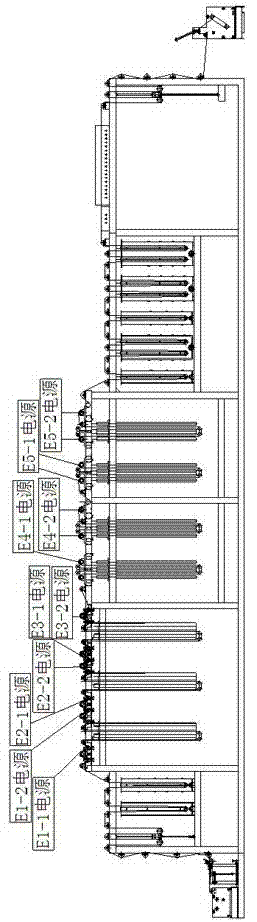

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as figure 1 As shown, the method of the present invention of the present invention at least comprises the following steps:

[0027] The method for corroding and expanding the surface of ultra-high voltage electrode foil is characterized in that the method at least includes the following steps:

[0028] 1) Raw material selection: choose the appropriate raw material aluminum foil;

[0029] 2) Pre-treatment: the purpose is to remove oil and oxides on the surface of raw aluminum foil; pre-treatment uses a concentration of 10-25% H by weight 2 SO 4 Solution, the temperature of the solution is controlled at 40-70°C, the treatment time of aluminum foil in the solution is 1-5min; the pretreatment is carried out in the acid tank;

[0030] 3) Water washing: the aluminum foil obtained in step 2) is washed with water; the purpose of water washing is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com