Capacitor lead processing method

A treatment method and capacitor technology, which is applied in the direction of fixed capacitor leads, capacitors, capacitor manufacturing, etc., can solve the problems of corrosion of lead wires and circuit boards, troublesome processing, uneven sagging of tin-lead plating, etc., and achieve good solderability and electrical connectivity, easy disposal and recycling, and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, embodiments of the present invention will be described below, and those skilled in the art can easily understand other advantages and efficacy of the present invention, apparently, as described in the present invention. , Not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

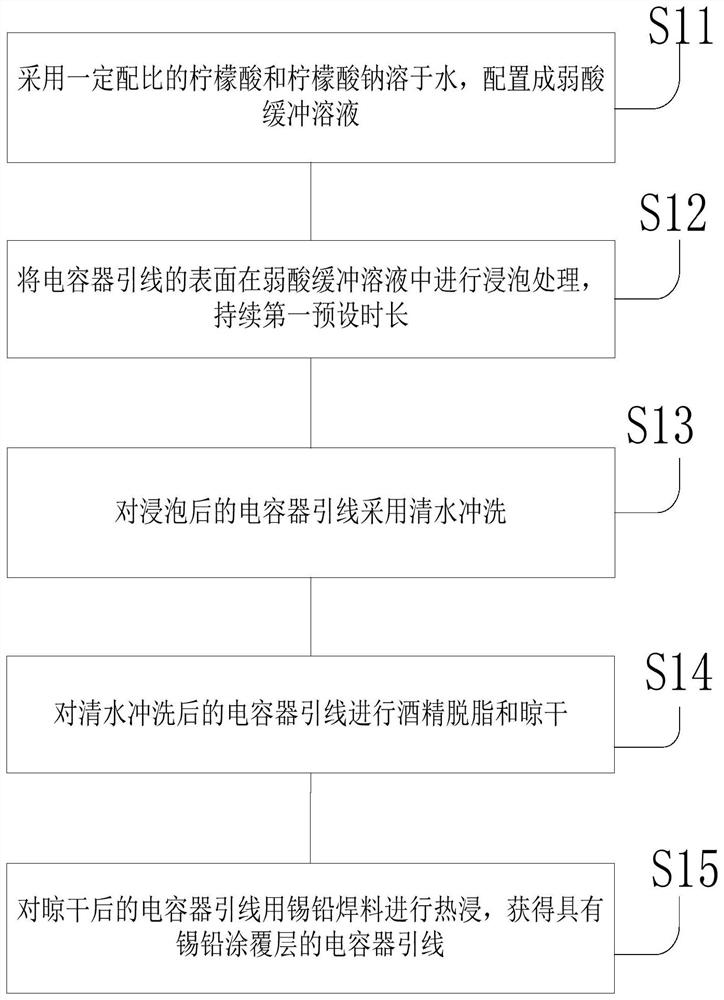

[0028] According to an embodiment of the present invention, a method of processing a capacitor lead is provided, such as figure 1 As shown, including:

[0029] S11, using a certain ratio of citric acid and sodium citrate to water, configure it to weak acid buffer solution;

[0030] S12, the surface of the capacitor lead in a weak acid buffer solution is subjected to a first preset time;

[0031] S13, flushing the soaking capacitor leads;

[0032] S14, the capacitor lead after purined water is alcoholized and dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com