Laser metal layer removing device of metallized film capacitor winding machine

A metallized film and metal removal technology, applied in the direction of wire wound capacitor machine, metal surface removal regulations, etc., can solve the problems of poor applicability, laser generator metallized film adjustment, etc., to achieve good removal effect and improve the effect of applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

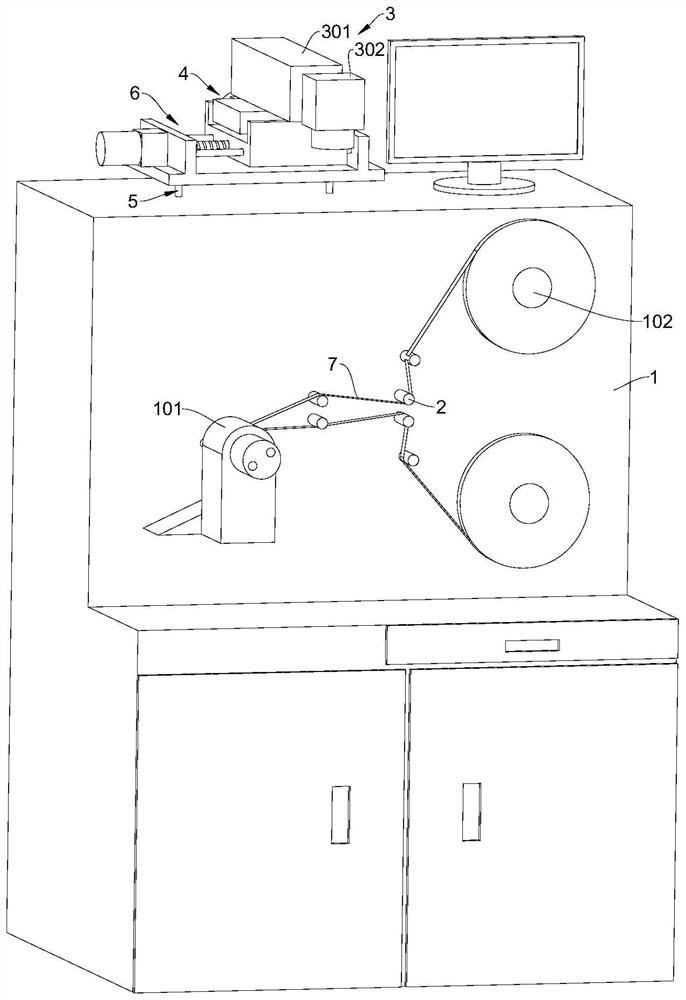

[0040] A metal film capacitor scroll machine laser clearing the metal layer device, including a rolling machine with 101 roll -up mechanism 101 and at least one roll -up mechanism 102. The institutional 101 rolls into the core (also known as Suzi). The closing mechanism 101 can be the same as the existing technology, that is, the rotation of the roller is achieved. Active rollers can drive rotation by connecting to the driver motor. The roller used for rolls does not require power. Of course, in other embodiments, the rollers used and the rollers used for rolls can also be connected to the driver motor, so that the speed of the two can be the same, and it can also achieve the collection and rolls.

[0041] There are two examples of the rolls in this embodiment, which can be wrapped in two layers of metallic film 7. Two thin membranes are superimposed together during the wound, forming a double -layer structure core. In practical applications, only one of them can be used.

[0042]...

Embodiment 2

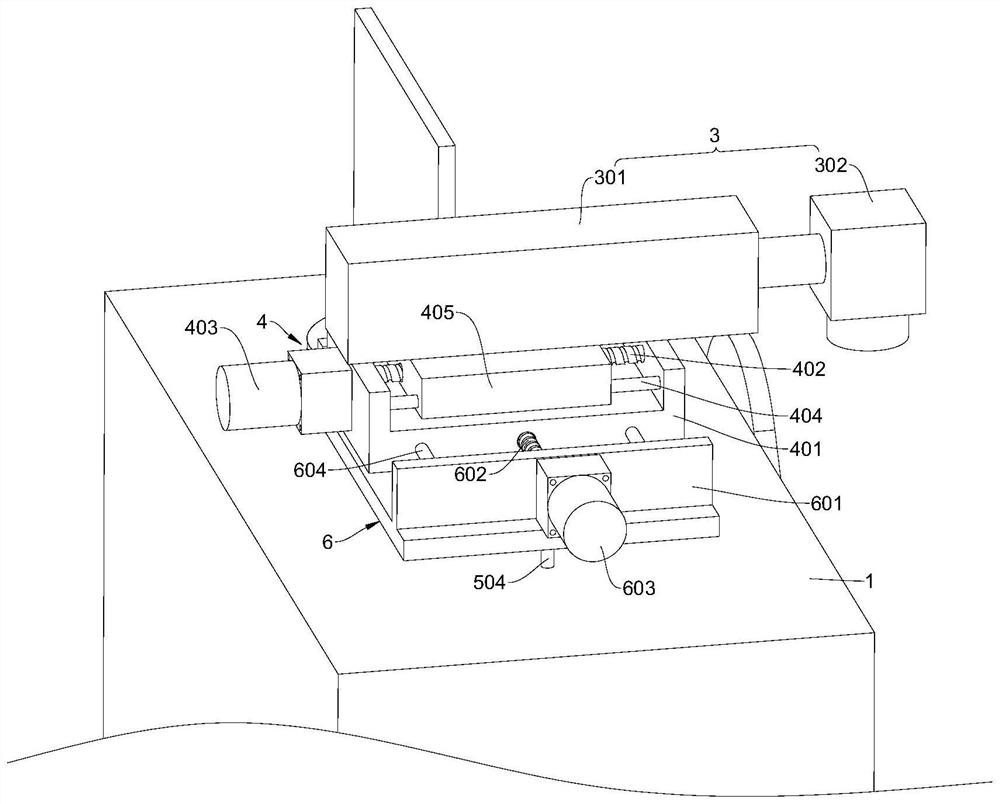

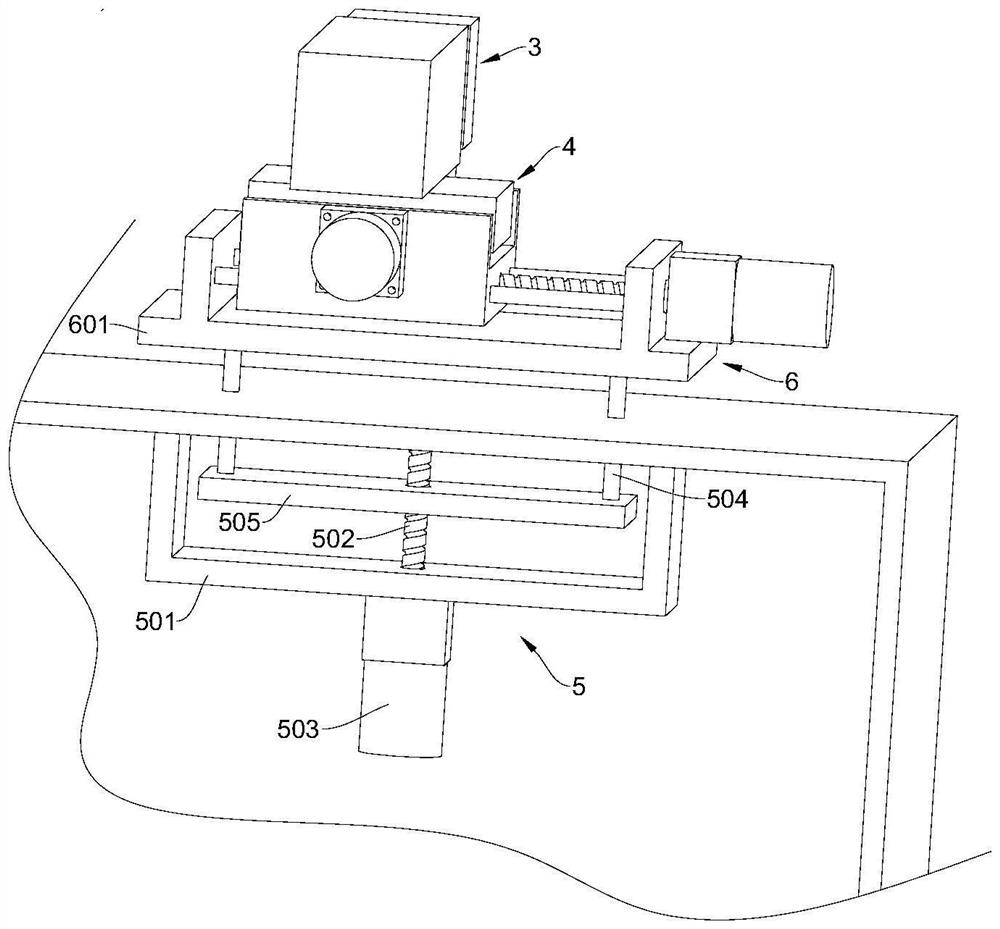

[0052] The difference between this embodiment and Example I is that the structure and embodiments of the X to regulating mechanism 6, and Z to the adjustment mechanism 5 are different.

[0053] In this embodiment, Y to the regulatory agency 4 includes the first driver element, and the first driver element is an electric push rod, a hydraulic push rod or a cylinder. The component drives the laser removal device 3 displacement, thereby adjusting the position of the laser removal device 3 in the direction of the width direction of the metallic film 7.

[0054] X to the regulating mechanism 6 includes the third -wheel drive component, the third -wheel drive element is an electric push rod, a hydraulic push rod or a cylinder. The overall displacement of the regulatory mechanism 4 and the laser removal device 3, thereby adjusting the position between the laser removal device 3 at the closing mechanism 101 and the release mechanism 102.

[0055] Z to the regulating mechanism 5 includes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com