Integrated sedimentation device with enhanced flocculation function

A sedimentation device and flocculation technology, applied in the feeding/discharging device of the sedimentation tank, the sedimentation tank, etc., can solve the problems of large capital investment in installation, large disturbance of sedimentation tank, large internal water pressure, etc., and meet the requirements of compressive performance The effect of lowering, simple and quick management, and overall height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

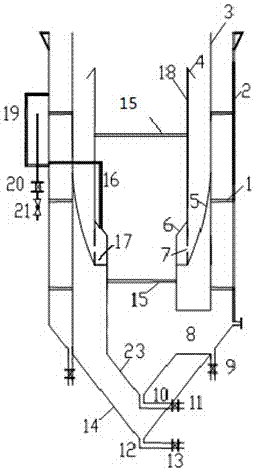

[0032] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

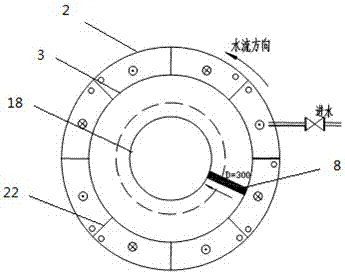

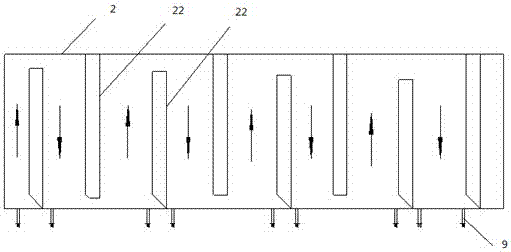

[0033] see figure 1 and figure 2 , the whole equipment main body of the present invention is made of 304 stainless steel, fixed on the bracket made of No. 10 channel steel, the upper structure of the device is cylindrical, and the main functional areas are sedimentation area and flocculation area; the lower structure is conical cylindrical , the main function is the sludge thickening area.

[0034] The flocculation zone is divided into two stages, including a central flocculation cylinder 18 and an outer ring flocculation cylinder 2 arranged concentrically, and a sedimentation zone 3 is concentrically arranged between the central flocculation cylinder 18 and the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com