Toothed rack angle lapping machine

A technology of rack and angle grinding, applied in gear cutting machines, gear tooth manufacturing devices, gear teeth, etc., can solve the problems of low machining accuracy, poor consistency, time-consuming and labor-intensive, etc., and achieves easy installation of components, not easy to stick, and convenient processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with specific embodiments in conjunction with the accompanying drawings.

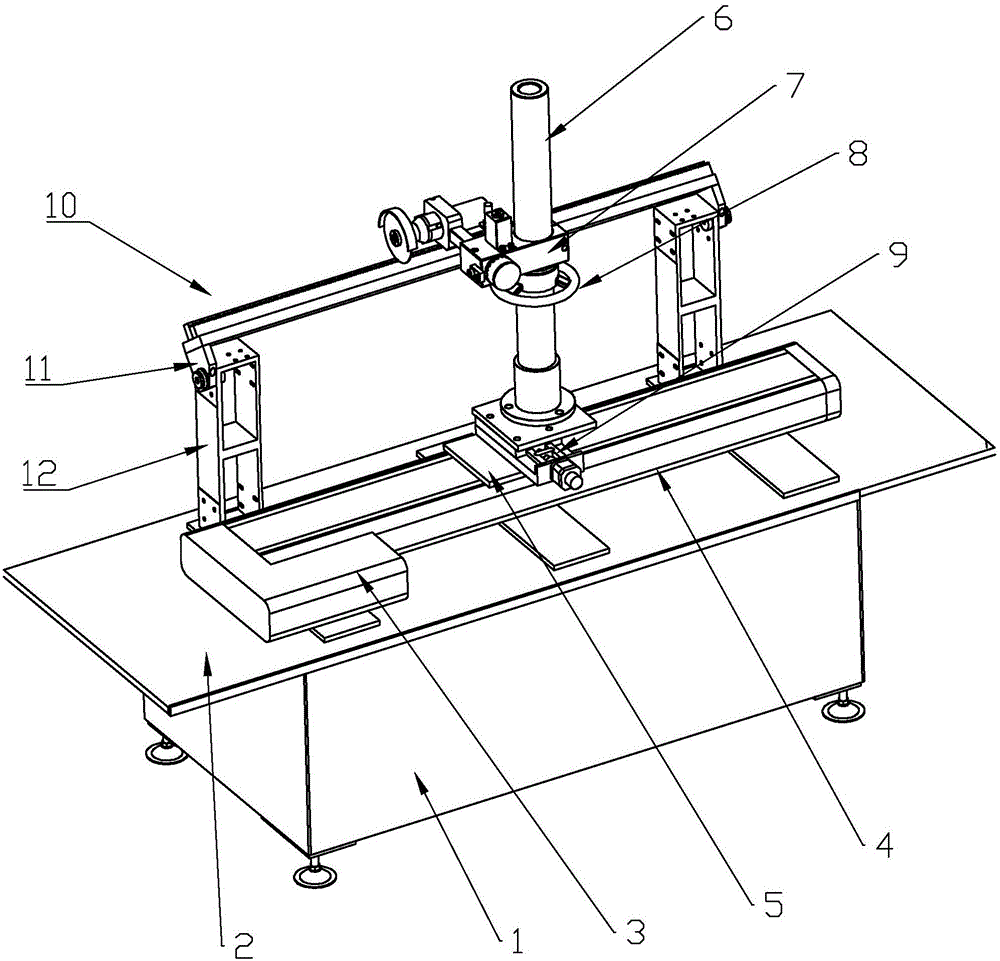

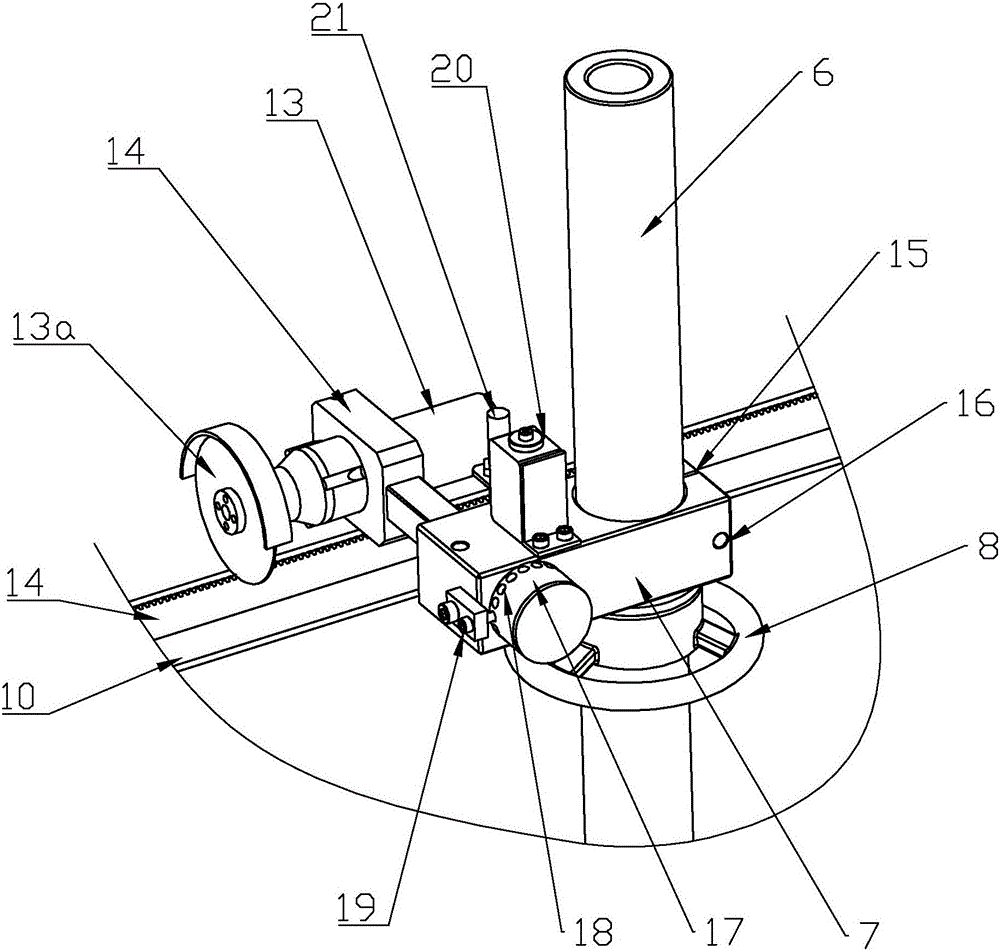

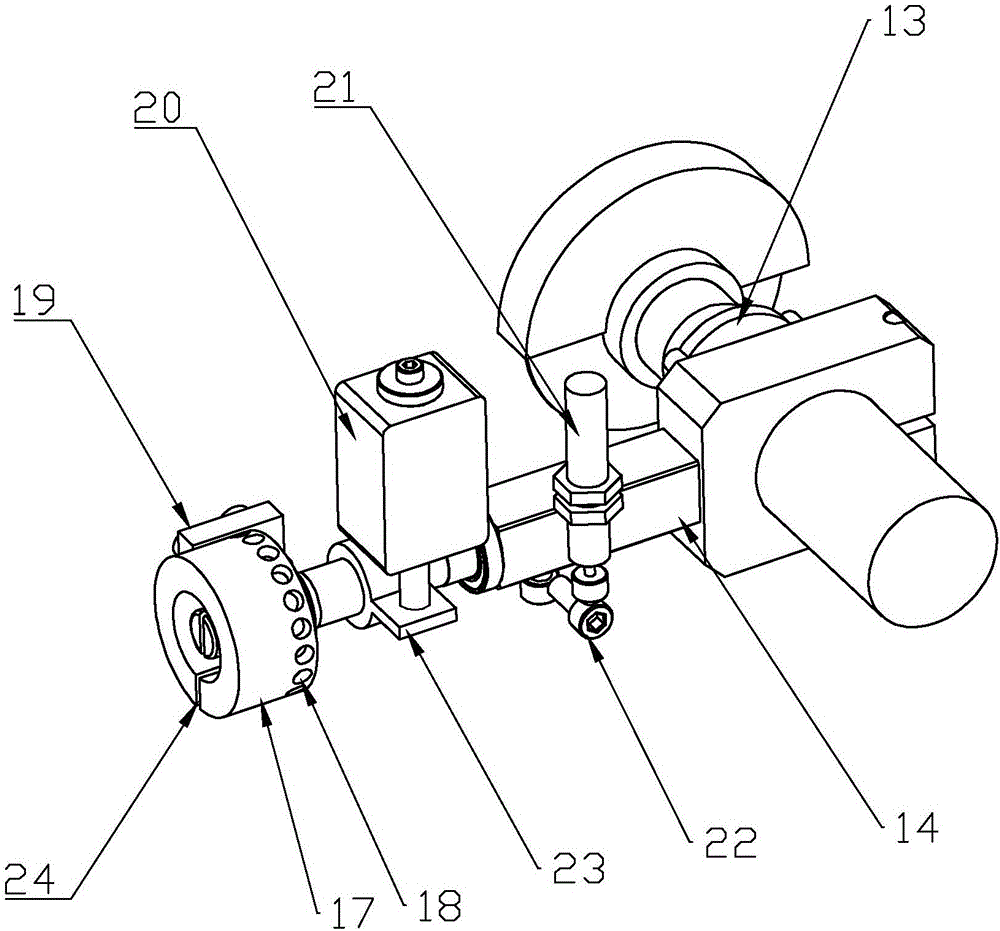

[0033] A toothed rack angle grinding machine, comprising a frame 1, a workbench 2 is fixed above the frame 1, a transverse traveling mechanism and a rack placement frame 10 are arranged on the working platform 2, and the transverse traveling mechanism includes a transverse sliding track 4. The servo motor 3 as the power source, the rack placement position of the rack rack 10 is parallel to the lateral sliding track 4; A cylindrical column 6 is provided above the slide plate 5, and a screw pair 9 adjustment structure is provided between the base of the column 6 and the slide plate 5 to realize vertical fine-tuning of the column 6 relative to the lateral sliding track 4; the surface of the column 6 is provided with threads, and The handwheel 8 is threaded, and the top of the handwheel 8 is supported with a sliding block 7. The tail of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com