Open end wrench capable of being wrenched to and fro

A technology of open-end wrench and slider, which is applied in the field of open-end wrench, can solve problems such as unsmooth structure operation, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

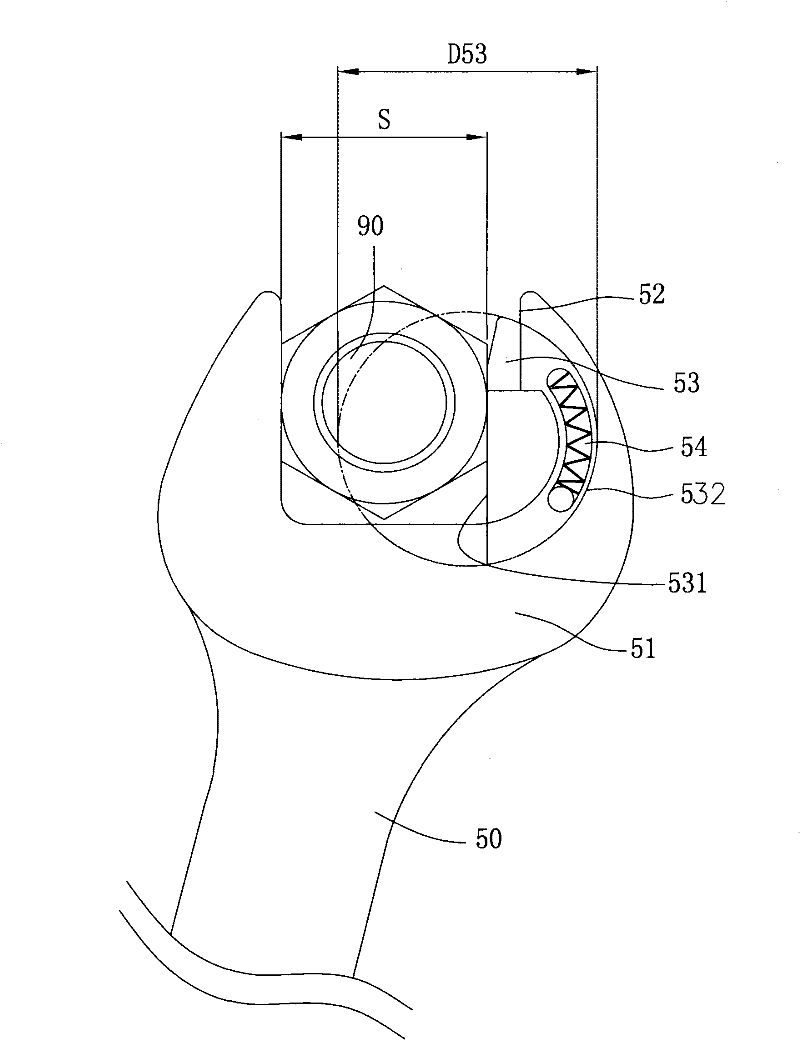

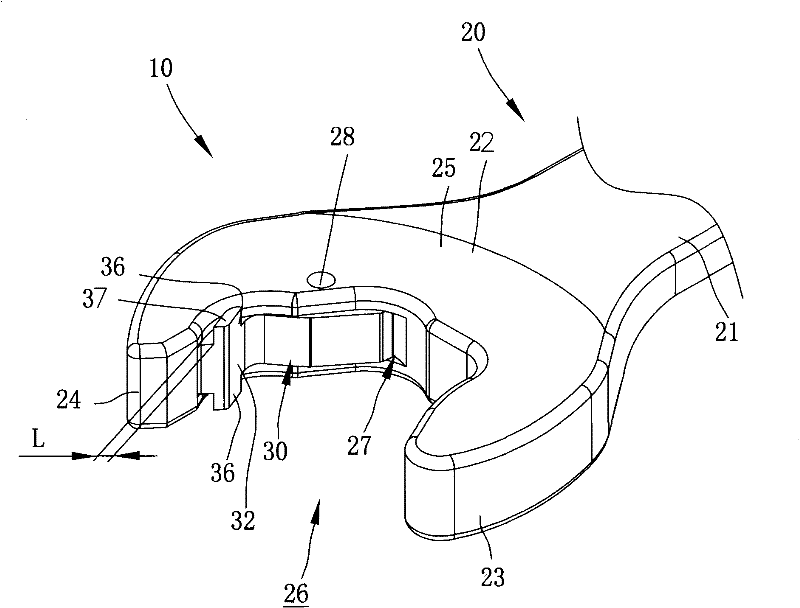

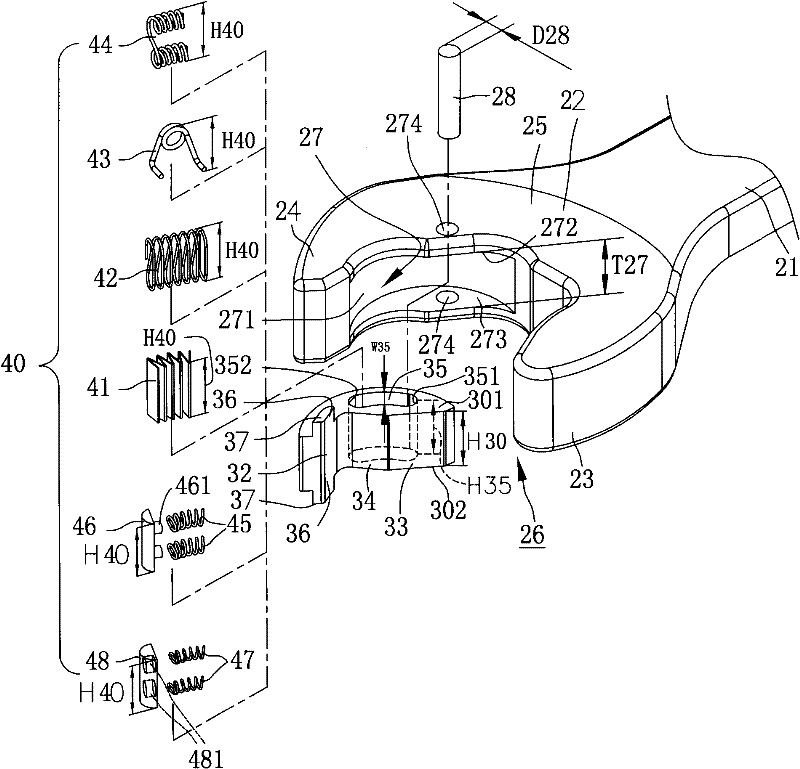

[0064] Regarding the technology, means and effects thereof adopted in the present invention, a preferred embodiment is given and described in detail in conjunction with the drawings as follows, with reference to Figure 2 to Figure 4 ,as well as Figure 7 to Figure 12 The open-end wrench 10 of the present invention includes a body 20 , a slider 30 and an elastic device 40 ; wherein: the body 20 has a grip portion 21 and a jaw 22 disposed at the front end of the grip portion 21 . Jaw 22 can connect working object 90, such as the hexagonal head of a bolt. When the working object 90 is a hexagonal head of a bolt, the six force-bearing surfaces are arranged counterclockwise in a ring at the six o'clock direction of the hexagonal head. Similarly, a positive force-bearing surface 91A to a sixth positive force-bearing surface 96A also have a first reverse force-bearing surface 91B to a sixth reverse force-bearing surface 96B. The user can hold the grip portion 21 and turn the body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com