Secondary fast forming machine for sole material

A shoe sole material and molding machine technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of the threat of the operator's working environment, the inefficiency of equipment use, the loss of energy from the transfer plate, etc., and achieve the temperature change of the working environment. Low, reduce the frequency of failures, improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

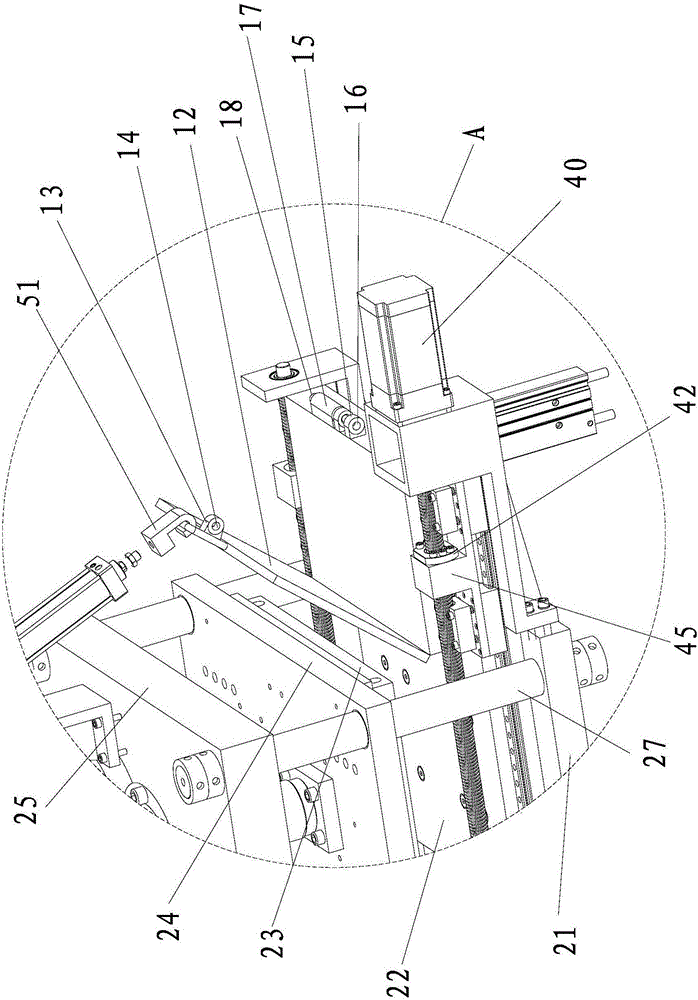

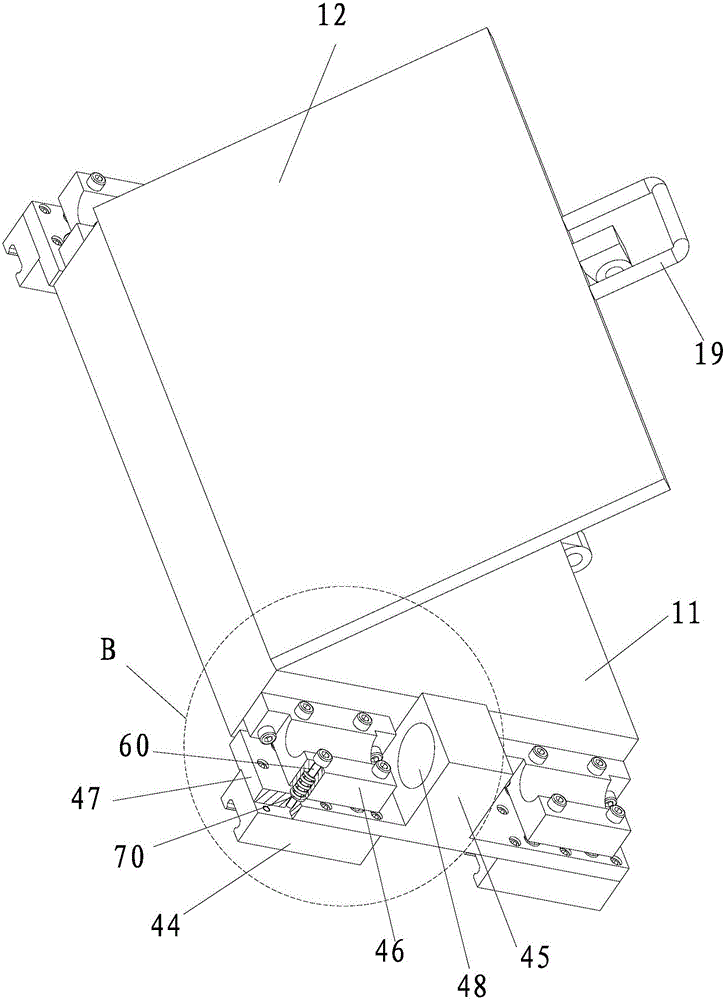

[0078] As the first embodiment of the bolt driving mechanism, the bolt driving mechanism includes a No. 1 locking mechanism 81 for pushing the No. 1 bolt 18 into the No. 1 lower connecting hole 16. Between the cooling mold station 20 and the heating mold station 30, a No. 1 unlocking mechanism 82 for pushing the No. 1 latch 18 away from the No. 1 lower connecting hole 16 is also included. The No. 1 unlocking mechanism 82 corresponds to the No. 1 cooling mold station 20 set up. With this structure, automatic mold locking and automatic mold opening can be realized. During operation, before the heating of the No. 1 mold 10, the No. 1 latch 18 is inserted into the No. 1 upper connection hole 14 and the No. 1 lower part through the No. 1 mold locking mechanism 81. In the connection hole 16, the locking of the No. 1 mold box 11 and the No. 1 mold cover 12 is realized. After the No. 1 mold 10 is cooled, the No. 1 latch 18 is connected from the No. 1 upper connection hole 14 to the No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com